Reducing Energy Use with Solar Transpired Walls in Poultry Houses

By Sanjay Shah, BAE Dept., North Carolina State University Bob McGuffey, North Carolina Solar Center, published in the North Carolina Poultry Industry Joint Area Newsletter. The Energy Information Administration reported that in North Carolina, wholesale propane prices increased by a whopping 67% to $1.67/gallon in January 2008 compared to January 2007.However, it is not just the increase in price but the market uncertainty that makes decision making difficult. Propane prices largely depend on demand and though we had a relatively mild December 2007, we saw many colder-than average days in January 2008. Since energy is a large part of poultry production cost, reducing energy use has the potential to somewhat cushion the effects of the volatile propane market.

The poultry industry has been watching this situation carefully and has been active in trying to reduce energy use through better maintenance and by adding insulation. Producers have made bigger investments to reduce energy use, such as, replacing the less efficient pancake brooders with the infrared tube heaters. The USDA can also help through the Renewable Energy and Energy Efficiency (REEE) Program. It can offer grants, guaranteed loans, and combination grant/guaranteed loans to animal producers to make energy efficiency improvements and install renewable energy generators. (For more details, go to: http://www.rurdev.usda.gov/rbs/farmbill/). The USDA will fund solar energy projects because it is renewable and it also reduces air pollution by reducing the release of gases such as carbon dioxide. Furthermore, in NC, you can sell renewable energy to your electricity provider at $0.21c/unit. You also get substantial federal and state tax credits when you make renewable energy investments. These factors have increased interest in using solar energy in animal houses.

Transpired wall at INTEK in Aberdeen, NC.

Solar energy can be used in two ways to the meet the energy needs of poultry houses, namely, (a) using photovoltaic (PV) cells and (b) using transpired walls. Using the PV method, solar energy is converted into electrical energy by PV cells on solar panels. A typical broiler house may need about 8 to 10 kW to meet the electrical energy demand and an array of PV cells may be able to meet a large portion of the demand most of the year. The PV method may cost $45,000 to $60,000 per house with paybacks of 5 to 9 years, after you include account federal and state tax breaks but without any USDA support. The shorter payback period is when you sell excess energy at $0.21c/unit. Due to the high initial investment and relatively long payback with the PV method, many producers may be inclined to take a wait-and-watch approach. The lower cost transpired walls may be appealing to producers who are more interested in reducing heating costs.

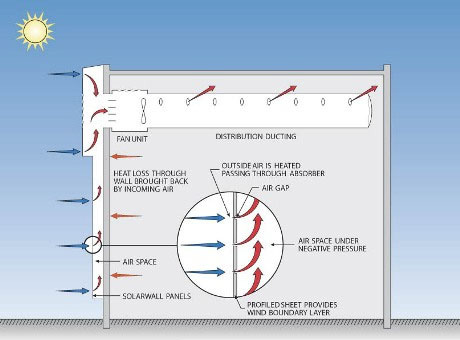

Transpired walls have been used in industrial and commercial buildings in Canada, Germany, and even in North Carolina (Figure 1). The transpired wall consists of a dark-colored porous metal wall that is placed on the sunny side the house. When air is drawn through the minute holes in the transpired wall, which being a solar collector, will heat up the passing air. The US Dept. of Energy reports that the incoming air can be preheated by as much as 40°F though the actual heating will depend on the orientation of the wall (south facing wall is the best) and cloud cover. Figure 2 shows how the transpired wall works at the facility in Aberdeen, NC shown in Figure 1.

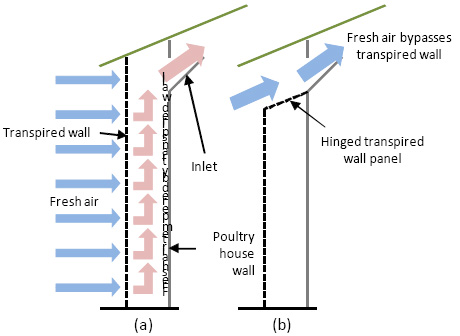

It should not be too difficult to use the transpired wall in broiler or turkey brooder houses. It should be placed on the sunny side the house, in front of the ceiling or wall inlets (Figure 3). During brooding or in winter, when the minimum or mild weather fans come on opening the inlets, air drawn through the minute holes in the transpired wall will be heated up. Given that air inside the broiler house has to be heated up to 92-93°F during the first week of brooding, tempering the fresh air during daytime under clear skies can result in substantial energy saving. Tempering 1,000 cfm of fresh air at 50°F and 50% relative humidity to 80°F (30°F increase) using a transpired wall will save nearly 2 gallons of propane over a 5-hour sunlight duration. (For reference, a 36 in. fan will move 9,000- 10,000 cfm at the house static pressure.) This tempered air is also drier (relative humidity of 18%) and will hence, be more effective in removing excess moisture from the poultry house. Further, reducing propane consumption by 2 gallons will also reduce carbon dioxide and water vapor buildup in the house by 15 and 10 lb, respectively, since these two compounds are formed when you burn propane. During nighttime in cool weather, the transpired wall will reduce heat losses from the house. Even in summer, when tunnel ventilation is being used, the transpired wall will reduce heat gain from the sun by shading the house walls. An important benefit of the transpired wall is that maintenance is minimal since it has no moving or liquid components. However, it is important to prevent accumulation of dust and debris on the transpired wall which can reduce the ventilation rate.

Figure 2. How the transpired wall works at the INTEK facility in Aberdeen, NC

However, transpired walls may not be for everyone. You need to consider the orientation of your poultry house. In the northern hemisphere, we get the most sunlight on the south side during winter and on the north side during the summer. So, where winter heating is important, a poultry house built along the east-west axis will allow you to install the transpired wall on the south, though southeast and southwest facing walls are also acceptable. In cooler western North Carolina, which has a large poultry industry, north facing transpired walls will help during summer brooding. The transpired wall will also reduce the ventilation rate by increasing static pressure; so, you will need to run your fans longer. While there are no studies done in poultry houses using transpired walls, your heat energy savings will likely offset your increased electricity use. Also, during transitional or mild ventilation (between minimum and tunnel ventilation), to prevent the fresh air from being tempered, a panel of the transpired wall could be hinged (Fig. 1), thus allowing the fresh air to bypass the transpired wall.

Recently, the North Carolina Solar Center did a study on installing transpired wall in a broiler house in eastern NC. The total cost of installing a transpired wall was $11 per square foot with after tax payback period of 13-14 months, without any USDA support. As a start, a poultry producer could consider installing enough square footage of transpired wall on the south side that would cover half of the minimum ventilation rate provided by, say, two 36-in. fans (small birds and/or cold weather). The other half of the air would come from the north side that has no transpired wall. Since the two fans would require a total of 15-16 inlets, to cover the eight 44-in. inlets on the south side, you would need a total area of about 500 sq. ft. of transpired wall which would cost about $5,500 per house. If the USDA were to provide a 25% grant, your cost would be correspondingly lower. Of course, you would also qualify for Federal and state tax credits for improving energy efficiency that would amount to more than 65% of the remaining cost. So, if your heating season is long, you raise smaller birds (i.e., you run more flocks through the house), and the orientation of your houses are favorable for installing transpired walls, you may want to give transpired walls serious thought.

April 2008