Sustainable Poultry: Production Overview - Part I

By Anne Fanatico, NCAT Agriculture Specialist - This is the first of three article's from the National Center for Appropriate Technology (NCAT) which provides information on raising poultry on pasture, including descriptions of production systems and facilities, as well as detailed nuts-and-bolts information.

Foreward

Alternative poultry production, especially pasture-based production, offers opportunities for producers interested in boosting incomes, diversifying operations, and providing a specialty product for consumers.

Americans eat a lot of poultry products - in 1999, we ate an average of 95 lbs. of poultry meat

and 258 table eggs each (1). Per-capita consumption of poultry meat has increased steadily since

the 1940s. This trend is largely attributable to consumer interest in low-fat foods, which has

driven a major decline in the consumption of red meat. Other health concerns, as well as environmental and animal-welfare issues, have created a strong demand for alternative poultry products raised in a 'natural' way, without routine medication such as antibiotics.

The focus of this ATTRA series is sustainable poultry production. Whereas most available poultry information is aimed at either large-scale or backyard production, this publication offers

hard-to-find current information on small commercial flock production - including many valuable insights from U.S. range poultry farmers, gleaned from computer discussion groups. Since the information presented here is rather detailed, beginning poultry farmers may want to start with SAN.s booklet Profitable Poultry: Raising Birds on Pasture, available through ATTRA. General information on backyard poultry production - including topics such as incubation, hatching, brooding, culling, layer management, and molting - is readily available from books, magazines, and Extension publications. One particularly valuable book is Gail Damerow's A Guide to Raising Chickens (2).

Conventional Poultry and Range Poultry Industries: Snapshots

Conventional

|

Confinement housing is high-density - broilers are raised on litter in houses of 20,000 birds, while layers are raised in cages in houses of 40,000 to 100,000 birds. Growers are generally responsible for disposing of the litter and carcasses, but integrators may take more responsibility for this in the future. Nutrient management plans are becoming more commonplace. "Least-cost" diets are formulated to provide an optimal balance of nutrients and usually contain livestock by-products such as meat and bone meal, feathermeal, etc., as well as routine medication.

Broiler genetics are "Cornish cross" (Cornish x White Rock), and layer genetics are Leghorn (white eggs) and Rhode Island Red and New Hampshire (brown eggs). Nutrition and genetic selection have sped up the grow-out period, so that broilers are ready for market at only 6.5 weeks and weigh about 4.5 lbs. live. Birds are processed in large company-owned plants - some plants process a million broilers a week. Cut-up and other further processing yield large profits to companies and convenience to consumers, especially in the form of fast food. The U.S. exports a lot of poultry meat - especially dark meat. About 8 billion broilers are produced each year in the U.S., bringing in $14 billion.

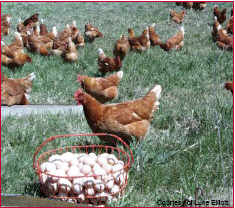

Range

"Pastured poultry production" is a grassroots movement that focuses on farm-scale production and direct marketing. It has been developed from the ground up by hundreds of family farms, and is driven by consumers seeking an alternative to conventional poultry. This enterprise can provide supplemental income in rural areas. Small farmers raise poultry in "free-range" or pasture based systems that are part of a diversified farm.

Producers buy day-old chicks, usually through mail-order, from independent hatcheries. They generally use the same broiler genetics developed for the conventional industry, but use a wider range of layer genetics, including many heritage breeds. Most producers raise poultry seasonally, though some larger-scale growers pursue year-round production. Some producers use commercial sources of nonmedicated feed, but most work with a local feed mill to have custom rations made from natural feed ingredients. Broilers are usually grown for eight weeks.

There are very few independent government inspected processing plants where producers can take their birds for processing, and large-scale integrated companies do not process for independents. "Exempt" non-government-inspected processing is often practiced on-farm. In many states, exemptions in the federal Poultry Production Inspection Act allow a producer to raise and process 1,000 birds per year for direct sale to customers. Small-scale equipment is used for slaughtering birds by hand. A few egg producers have egg processing equipment, but most wash eggs by hand. The legal environment surrounding non-government-inspected meat processing presents both opportunities and limitations.

Marketing is usually direct to customers and advertising is often word-of-mouth. Farmers sell directly to customers, from the farm or at other locales such as farmers. markets, and report more demand than they can supply.

It is difficult to estimate the size of the pastured poultry movement; one way is to consider the number of books sold on the topic:

- Pastured Poultry Profits. 10,000 sold

- Free-Range Poultry Production and Marketing. 3,000 sold

- The Chicken Tractor. 35,000 sold

Although there are many producers, the operations are mostly small. A 1999 NCAT survey found that 46% of pastured poultry enterprises produce between 0 and 500 broilers per year; 17% produce between 501 and 1,000 per year; and 18% produce more than 1,000 per year (3). Sixty-nine percent also raise layers, and 31% also raise turkeys. Eighty percent indicated they would like to expand operations.

Although many producers are satisfied with farm-scale production and direct marketing, there is an industry emerging from the grassroots movement that looks beyond direct marketing. Labor intensity limits the number of birds that a producer can realistically produce and market from the farm. To earn more than supplemental income, producers need access to better processing and marketing. Some are building small government- licensed processing plants.

There are a few large-scale companies with national distribution of range and organic poultry

products (Shelton.s Poultry Inc. and Petaluma Poultry Processors, to name two); however, they

have not evolved with the pastured-poultry movement - they are industrial models. Most pastured-poultry farmers - even those building processing plants - are committed to sustainability

and do not seek national markets, but rather regional ones that support local food systems.

Why Raise Range Poultry?

Producers are interested in range poultry production for economic and for less tangible reasons.

Poultry is one of the first types of livestock that beginning farmers consider. Small-scale poultry production can be profitable with a low initial investment, and it provides good cash

flow. But the motivation may be a lifestyle issue. Some families use poultry production to

teach a work ethic to children. Home-schoolers in particular use it as an educational tool. Farmscale poultry production provides a summer job for teenagers and can be appropriate for youth

programs and other community development projects. Or people may simply want to raise chickens to have the meat and eggs available to family and friends.

From a production standpoint, the reasons to pasture birds are to obtain nutrients from the pasture, improve land fertility, and improve bird health.

Poultry obtain nutrients from young, vegetative forage plants, but because they cannot digest

cellulose as ruminants (cattle, sheep, goats) do, poultry do not make use of the vast energy

stored in the plant fiber. Besides plants, poultry on pasture also forage for seeds and live protein such as worms and insects. Pasture is usually planned and managed primarily for ruminants

in "extensive" range poultry systems.

Intensive vs. extensive is an important distinction in range poultry production systems.

- Intensive range poultry production can be a stand-alone enterprise and requires only a small amount of land. However, careful manure management is needed to prevent excessive soil fertility.

- Extensive range poultry production requires a lot more land and is usually part of a diversified operation with ruminants. Mixed husbandry can be very important in range poultry production. Buying land just for the purpose of extensively raising poultry is unlikely to be profitable. In addition, grazing ruminants shorten the grass for the poultry, eliminating the need for mowing. Increased farm diversity can enhance biological diversity and environmental quality.

Soil fertility is a major motivation for range poultry production. Many producers want to take advantage of range poultry manure to improve their pastures for ruminants. Range poultry, according to Oregon producer Robert Plamondon, is "almost essential in reviving a played-out farm on a shoestring budget". Some vegetable growers insist that in order to build a sustainable system, livestock must be incorporated into the farm for fertility. However, excessive soil fertility can also be an issue, especially in intensive systems.

Much of the fertility in poultry manure is derived from concentrate feed, an important input in poultry production. Layer manure has 1.5% nitrogen (N), 1.3% phosphorus (P), and 0.5% postassium (K) (4). Broiler manure is usually mixed with litter. Birds deposit a lot of their manure in the house at night. These "night droppings" can be removed and spread directly on pastures, or composted first.

Litter is a large-scale problem in the conventional poultry industry. When too much litter is applied to the ground, nutrient pollution occurs (overfertilization with phosphorus) (5, 6). However, in small-scale production, litter is usually an asset rather than a problem, because the volume is much smaller. Excessive fertility on poultry range can be managed by grazing with ruminants, by making hay, or by rotating crops, since these activities remove nutrients.

Many beef producers also keep poultry to scratch apart larva-harboring dung pats to reduce

fly and parasite problems on the cattle. Producer Joel Salatin in Virginia has said he would keep

layers in his cattle pastures even if there were no eggs.just for the health benefits to the cattle. Many producers believe that birds are healthier and happier when raised on pasture.

Raising small outdoor flocks can reduce the concentration of disease-causing pathogens, and UV

light from the sun is a good sanitizer. Still, birds will be exposed to pathogens from wildlife, and pathogens can build up in intensively used areas. Also, exposure to the elements and stress

from predation may have negative impacts on bird health.

From a marketing standpoint, birds raised on pasture appeal to some consumers for welfare or aesthetic reasons, or because they believe pasture production is more environmentally sound, or because they believe the meat and eggs are more nutritious or better tasting. Some like the deep orange color of the yolk when layers eat plant material. When direct marketing, a broad range of products is an advantage, in addition to increasing diversity on the farm.

Further Sections

To continue reading the article, please click on the links below

Source: National Center for Appropriate Technology (NCAT) - February 2002