Layers Get Special Treatment at 'Heavenly' Farm

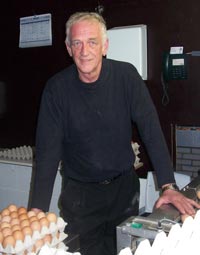

Attention to detail is the key to success at Himmelsfarm in the Netherlands, writes Jackie Linden, editor of ThePoultrySite, after a recent visit.Rinus and Conny Stuijts are not ordinary egg farmers. They were not raised on a farm but Rinus dreamed of having his own egg farm during his career as a tram driving instructor in the city of Rotterdam. What started as a hobby has become a healthy business.

In 1996, the Stuijts' dream came true when they set up Himmelsfarm (Heaven's Farm), which was one of the largest barn egg farms in the Netherlands at that time. Today, there are three houses on the farm, with around 32,000 H&N Brown Nick birds.

In the past, all houses there where equipped with a traditional flat deck system with each a capacity for 7,500 birds. Three years ago, Rinus changed one of the houses to a Bolegg Terrace aviary system from Vencomatic. The retrofit house now has a capacity of 17,000 birds, at a stocking density of 18 birds per square metre house area and nine birds per square metre liveable area, including the aviary system.

That means that the capacity in retrofit house has more than doubled, compared to the flat deck system with the traditional nest boxes.

"For me it's not possible to expand the company in number of houses on this location, therefore retrofitting the house was the perfect solution for me." Mr Stuijts said.

The choice for Vencomatic was not a difficult decision. "In my old houses, we also had the Vencomatic nest in the traditional layout. As this works fine and gives perfect quality eggs, I choose again for the Vencomatic system," he explained.

The Bolegg Terrace aviary system of Vencomatic has an integrated nest box, perches, feeders, drinkers and manure belts. Due to the design of the system, the hens can easily move up in the system, without having to jump from one row to another. The system is also designed around the birds' natural behaviour. For instance, most perches are up in the system, so all birds can perch high up at night.

Problem-Free Flocks Need Minimum Labour

When asked what is the biggest challenge on the farm, Mr Stuijts mentioned cleaning the houses between flocks. He and his wife manage the farm day-to-day with minimal extra help so the dismantling, cleaning, sanitation and re-construction stages add greatly to the workload. Therefore, they hire some extra employees at the time of cleaning.

Limited labour was also the Stuijts' reason for choosing the new aviary house: easy management, for example, and minimal floor eggs. During the visit, Mr Stuijts explained that he finds a maximum of 20 floor eggs per day.

"I check the house every morning. If you can now find more than 10 eggs now, I will give you one Euro for every egg you find," said the confident poultry farmer at 16:00 hrs. in the afternoon.

While Rinus checks the houses in the morning, his wife Conny starts with egg collection. When he finishes his control round, he takes over egg collection. In this way, they are normally finished with egg collection before lunch. In the afternoon, Rinus runs a second egg collection because he wants to have all eggs out of the house every day. Of course, this is extra workload, but egg quality is improved.

The success of a problem-free flock starts with the placement of birds in the house, said Mr Stuijts. Of course, the hens should be reared well but also lots of efforts are put into the management at the start of the flock.

"When I receive new birds, I live in the house. By taking away any possible floor eggs directly, I teach the birds that they should lay the egg in the nest," he said.

Also every flock needs a slightly different management. "In the beginning, I spend lots of time in the house to get to know my birds. This pays off later in the flock," he added.

Attention to Detail Wins the Day

The Stuijts' attention to detail is remarkable, and it was clear that Rinus, who works in the houses, cares for the health and welfare of all his birds. He can tell you exactly how many birds are in each house, and for example that mortality in the new house had been 249 birds to 51 weeks, under two per cent. He also tells you without hesitation that today the birds are laying 93.8 per cent at 51 weeks.

The birds are fed five times per day, the first time 15 minutes after the light switches on at 04:30 hrs. in the morning. The second feed is at 10.00 hrs because in Rinus's opinion, hens should not be disturbed during their period of lay. "Running the feed tracks while birds are laying eggs in the nest could cause hens to be attracted out of the nest." The rest of the feed runs are spread over the day.

In order to prevent feather pecking, Rinus uses dried lucerne, which he spreads on the floor. He explained that he finds that a better alternative for straw, which can be infected with Salmonella.

Eggs are collected from the farm three times each week, and sold to an egg trader, Zonnefarm – 200,000 per week. All of the Himmelsfarm eggs go to Switzerland, where their special yellow yolk colour is highly valued.

The Himmelsfarm eggs achieve their desired colour not via feed supplements but through the feed, which contains a high proportion of maize. Mr Stuijts specifies with the feed company that the feed should contain a minimum of 55 per cent maize, two per cent wheat and 2.5 per cent barley, and be coarsely ground.

Rinus Stuijts also believes in the power of natural supplements. To keep his birds healthy and the eggs top quality, he includes a different natural product each day of the week, including copper sulphate, zinc for good feather condition, vinegar and a cinnamon product.

It seems it's all part of the secret of success at Himmelfarm!

July 2009