How Do Tunnel Inlet Doors Affect Air Velocity Distribution in Tunnel Houses?

There will always be variation in air velocity in a tunnel-ventilated broiler house, and therefore a variation in bird cooling. From the University of Georgia, Michael Czarick (Extension Engineer Extension) and Brian Fairchild (Poultry Scientist) explain what producers can do to minimise the variation.

Often the bird-cooling ability of a tunnel-ventilated poultry house is measured in terms of average air velocity. An average air velocity is generally determined by averaging multiple air velocity measurements taken across the cross-section of a house approximately 100 feet from the tunnel fans.

Though this will provide some measure of how capable a house is of keeping birds cool during hot weather, air speed uniformity is of equal or possibly greater importance. For instance, assume we had two houses that both had an average air speed of 600 feet per minute but in one, the air speed near the outside water line was 400 feet per minute, while in the second house it was 500 feet per minute. Can we say that both houses will do an equal job of keeping market age birds cool on a hot summer day?

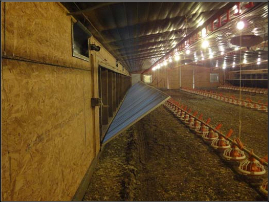

Though there will always be variation in air velocity in a tunnel house, and therefore a variation in bird cooling, there are things producers can do to keep variations to a minimum. For instance, the velocity of the air in a tunnel house will always tend to be lower in the vicinity of the tunnel inlet and tunnel fan end walls. Air movement near the tunnel inlet end wall can be maximised by making sure the tunnel opening starts as close as possible to the end wall, installing a pad as tall as possible (i.e. six-foot instead of five-foot tall pad), as well as installing tunnel doors (Figures 1 and 2).

right: Figure 2. Six-foot-tall pad system.

Air movement near the tunnel fan end wall can be increased by installing side wall tunnel fans as close to the end wall as possible, as well as installing a portion of the tunnel fans in the end wall of wider houses (Figures 3 and 4).

right: Figure 4. Tunnel fans in the end wall in 60-foot wide house

A more costly problem is that air velocities tend to be higher along the centreline of a tunnel-ventilated house and lower along the side walls. It is not uncommon to find air speeds near the side wall 200 feet per minute or more slower than in the centre of the house which, will result in dramatically different levels of bird cooling. Variations in air velocity across the width of a house are more problematic than those found near the end walls due to the number of birds that are potentially affected. For instance, if the air velocity is lower than desired within five feet of the side walls this will affect nearly 25 per cent of the birds; within 10 feet, 50 per cent of the birds will be affected!

There are a number of factors that affect how much the velocity of air will differ across the house width of a tunnel house, the most important of which are side wall obstructions (i.e. furnaces) and side-wall construction. Past issues of Poultry Housing Tips have shown that side-wall furnaces can reduce the air speed on the side wall 100 feet per minute or more. Side-wall posts or exposed wall studs can result in air speed differences from the centre to the side wall of the house of 200 to 300 feet per minute, resulting in substantial differences in bird cooling.

One of the summertime advantages of a totally enclosed house is that this variation in air velocity can be reduced to as little as 100 feet per minute when exposed studs are covered, making the side-wall smooth, and thus encouraging the flow of air along the wall.

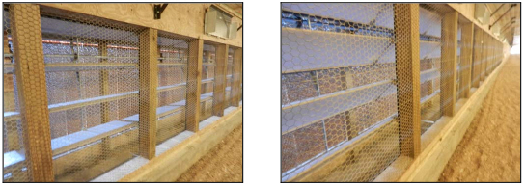

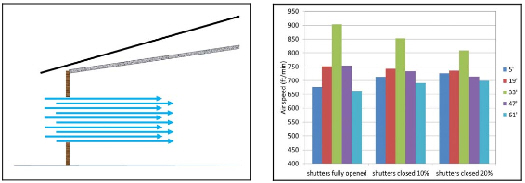

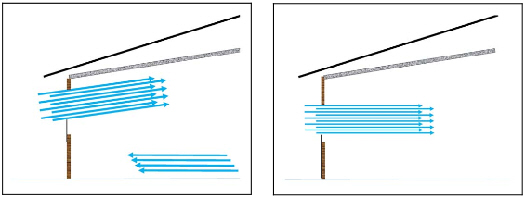

A recent study of a new tunnel inlet shutter system has demonstrated how the air enters a house can also have a significant effect on wall-to-wall air velocity uniformity throughout a tunnel-ventilated poultry house. A tunnel inlet shutter consists of a series of four pivoting insulated panels that resemble a fan shutter (Figures 5 and 6). The tunnel inlet shutter system has the advantages that it does not protrude into the house and seals very tightly.

right: Figure 6. Tunnel inlet shutter partially closed.

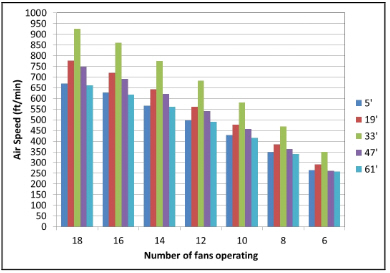

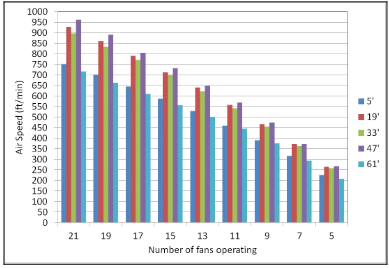

The study was conducted in two 66-foot × 500-foot totally enclosed poultry houses to examine what effect tunnel inlet shutters had on average house air velocity as well as wall-to-wall air velocity uniformity. The two study houses were identical other than one was equipped with tunnel inlet shutters while the second had conventional tunnel inlet doors. Each of the houses had 16 52-inch (1.5hp) and two 48-inch (1.5) tunnel fans with butterfly shutters and discharge cones along with 116 feet of five-foot-tall, six-inch pad on each side wall and 26 feet of pad installed in the end wall.

Five poles, with three anemometers on each pole, were evenly spaced across the width of the house approximately 100 feet from the tunnel fan end wall. The anemometers were mounted on each pole two feet above the floor, two feet below the ceiling and roughly 4.5 feet above the floor. Each of the 15 anemometers was connected to a data-logging system that recorded air speed every minute for 20 minutes. The 15 anemometers allowed a highly accurate determination of the average house air velocity.

Static pressure was measured 100 feet from the pad inlet end wall, 50 feet from the fan end wall, as well as at the centre of the house. With all fans operating, the average air speed in the house equipped with tunnel inlet shutters was 719 feet per minute. The static pressure was 0.13, 0.14 and 0.17 inches, 100 feet from the tunnel inlet end wall, half house, and 50 feet from the tunnel fan end wall, respectively. In the house equipped with traditional tunnel inlet doors, the average air velocity and static pressure measurements were virtually identical, 693 feet per minute, 0.13, 0.14 and 0.18 inches, respectively.

Though the average air velocity and static pressure measurements were virtually identical, there was a substantial difference in air speed distribution across the width of the two houses. In the house equipped with the tunnel inlet shutters with all the fans operating, there was over a 250 feet per minute difference in wind speed from five feet from the side wall to the centre of the house (Figure 7). In the house equipped with tunnel inlet doors, the variation was slightly less than 100 feet per minute (Figure 8).

The significant difference in air velocity uniformity is attributable to the way the two different tunnel inlet systems cause the air to move upon entering the house. A tunnel inlet door directs the air to the ceiling as much as the side wall inlets used during cold weather. The air moves along the ceiling then rotates back along the floor creating a very strong rotational air flow pattern (Figure 9). The rotational pattern of the incoming air helps to distribute the air across the width of the house and the smooth side walls help to maintain the uniform distribution of air across the width of the house as the air moves towards the fans.

In the house equipped with tunnel doors, the air entered straight into the house with little rotation as it does in a house equipped with tunnel curtains. The two air-streams entering from the side wall openings move straight to the centre of the house where they collide. The majority of the air does not rotate back towards the side wall because there is no easy way for it to do so (Figure 10). As a result, the air speeds tend to be higher toward the centre of the house than the side wall.

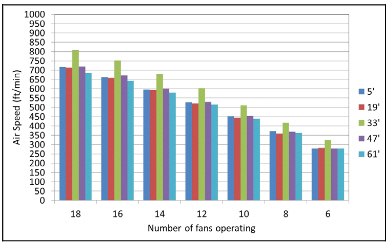

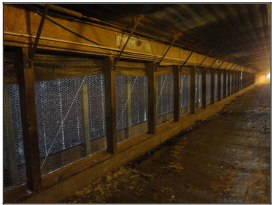

In an effort to create a similar incoming air flow pattern as was seen with the tunnel inlet doors, the tunnel inlet shutters were closed 10 per cent and then 20 per cent. By closing the shutters just 10 per cent, the slight tilt in the shutters encouraged a more circular pattern and the variation in air speed between five feet from the side wall and the centre of the house decreased to 150 feet per minute. When the tunnel inlet shutters were closed 20 per cent, a strong rotational pattern was created, decreasing the variation in air speed to less than 100 feet per minute, the same as that seen in the house with tunnel doors (Figure 11).

right: Figure 11. Air speed across width of house with all fans operating and tunnel shutters partially closed.

Though the static pressure increased when the tunnel inlet shutters were partially closed, it is important to realise that it is not the increased static pressure that improved wall-to-wall air speed uniformity but rather the creation of a rotational air flow pattern. By directing the incoming air along the ceiling, a tunnel inlet door allows the air to flow back toward the side wall along the floor thus creating the rotational air flow pattern (Figures 7 and 8).

The fact that the level of static pressure had little to do with the improvement of air velocity uniformity is confirmed by the fact that though the inlet static pressure was very low when six to 10 fans were operating in both houses (less than 0.03 inches), the house equipped with tunnel doors still had much less variation in air speed from wall to wall than the house with tunnel shutters. This to some extent explains why adjusting tunnel curtains based on static pressure improves wall-to-wall air speed distribution on some farms and not others.

If a tunnel curtain is located towards the top of a side wall and closes from the bottom when the curtain is partially closed - resulting in a higher static pressure - the air will tend to move along the ceiling, allowing the air to return near the floor (Figure 12). But, if the tunnel curtain opening is near the centre of the side wall it is more difficult for a circular air flow pattern to be created (Figure 13) and therefore air speed uniformity will not be improved

right: Figure 13. Tunnel curtain opening located in the centre of the side wall.

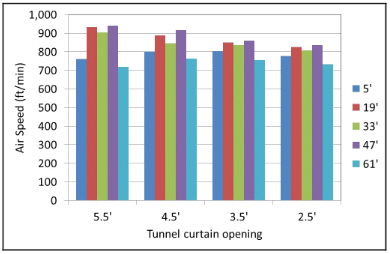

The effect that reducing the tunnel inlet curtain opening had on air speed uniformity was examined in a similar house (66-foot × 600-foot) on a third farm. The house had 21, 54-inch (1.5hp) and one 48-inch (1hp) tunnel fans with butterfly shutters and discharge cones along with 124 feet of six-foot-tall, six-inch pad on each side wall and 32 feet of pad installed in the end wall. The house was equipped with a five-and-a-half-foot-tall tunnel inlet curtain, which pulled open from the bottom (Figure 14). With all fans operating, the average air speed was 830 feet per minute. The static pressure was 0.14, 0.15 and 0.18 inches, 100 feet from the tunnel inlet end wall, half house, and 50 feet from the tunnel fan end wall, respectively.

As seen in the study in the house equipped with the tunnel inlet shutter system, the variation in air velocity across the width of the house was significantly greater than in the house equipped with tunnel inlet doors. With all the tunnel fans operating, the air velocity five feet from the side wall was 200 feet per minute slower than in the centre of the house. Unlike the house equipped with tunnel inlet shutters, the wind speed measured by the center three anemometer poles was fairly consistent, varying less than 50 feet per minute (Figure 15).

With all the tunnel fans operating, the tunnel inlet curtain was closed incrementally to determine if the wall-to-wall air velocity uniformity could be improved. Closing the tunnel inlet curtains one foot (18 per cent) reduced the variation in air velocity between the centre of the house and the side wall to less than 150 feet per minute. Reducing the tunnel inlet curtains an addition foot (36 per cent) to 3.5 feet reduced the variation to less than 100 feet per minute (Figure 16).

Though closing the tunnel curtain did improve air speed uniformity, the increase in pressure resulting from the smaller curtain opening decreased air speed slightly 10 and 30 feet per minute to the 4.5-foot and 3.5-foot openings, respectively.

It was not unexpected that the tunnel inlet curtain had to be closed as much as it did to reduce the variation in wind speed to 100 feet per minute or less. Since the five-and-a-half-foot tunnel inlet curtain took up a substantial portion of the seven-and-a-half-foot side wall, there was little room for the incoming air to rotate back towards the side wall. Though closing the tunnel inlet one foot did improve wall-to-wall air speed uniformity, the curtain had to be closed almost half-way to allow the circular air flow pattern to be established.

So although it is possible to improve wall-to-wall air speed uniformity by closing a tunnel inlet curtain, the same uniformity can be achieved with a tunnel inlet door without having to reduce dramatically the size of the inlet opening, which will lead to an increase in static pressure and reduction in overall air speed.

Obtaining as uniform as possible air velocity across the width of a poultry house depends not only on having a smooth side wall free of obstructions but also on getting the air to enter the house correctly.

As during cold weather, our air should enter through an 'inlet' and not just an opening. An opening just dumps air into a house; a proper inlet not only allows the precise control of the amount of opening but controls the direction of the incoming air and therefore controls air distribution and mixing as well.

Though a tunnel curtain can be used as a tunnel 'opening', it is difficult to make it perform like a proper inlet. In order to make a tunnel inlet curtain perform like a proper inlet, it needs to be close to the bottom or top of the side-wall. Furthermore, the tunnel inlet curtain opening needs be closed enough so as to take up a relatively small portion of the side wall height to allow a circular air flow pattern to be created.

If a curtain is located near the top of a side wall, the curtain needs to close from the bottom up. Conversely, if the curtain opening is near the bottom of the side wall, the curtain needs to close from the top down. The problem, of course, is that although partially closing a tunnel curtain may improve air speed uniformity, it will also result in higher static pressures and a reduction in average air speed. Of course, the advantage of a tunnel door or shutter is that improving wall-to-wall air velocity distribution does not require a substantial restriction of tunnel inlet opening and, therefore, average air velocity will not be adversely affected.

Air velocity is the primary method of cooling birds in hot weather. Producers strive to provide a uniform environment throughout the house because a small change in air velocity can result in large differences in bird cooling. These studies demonstrate the ability the producer has to influence the uniformity of air velocity across the width of the house with minimal impact on static pressure and average air velocity.

September 2013