Four Common Minimum Ventilation Mistakes

The four basic requirements of successful minimum ventilation are explained by Jess Campbell, Jim Donald, Dennis Brothers and Gene Simpson National Poultry Technology Center at Auburn University College of Agriculture.In wintertime, most of problems growers, service technicians and managers call NPTC for help on have to do with wet floors, too high ammonia, high fuel bills and poor performance. More often than not these problems are the direct result of failing to meet one or more of the four basic requirements of successful minimum ventilation. It is easy to remember what these are if you think of the acronym POST:

Pressure – Adequate static pressure, usually around 0.10 inches or more, is required to get good “throw” of incoming cold air to mix with warm in-house air above the birds, not dropping to the floor and chilling them or causing condensation and wetting of litter.

Openings – To enable static pressure to do its air-throw job, you must have the right number of vent doors unlatched and opening properly, not too wide and not too tight.

Source – The correct ventilation setup (fans and vents) to bring all incoming air through the brood chamber.

Timing – Minimum ventilation fan on-off cycling time must be right for the size/age of birds so as to maintain proper air quality.

Getting any one of these four POST requirements wrong results in wet floors, too high ammonia, too high fuel bills, and poor flock performance. This article explains how to use POST to get them all right.

What is Minimum Ventilation?

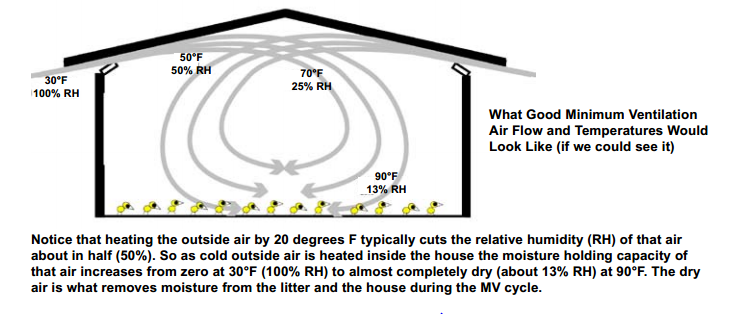

Minimum ventilation (MV) is the first stage of negative pressure ventilation in a poultry house where the amount of ventilation air exchange is dictated by a time clock setting or timer in the electronic controller, and not by temperature. MV begins when the in-house temperature is below the desired set point, typically on day one during brooding in cold weather and heating systems are operating. The controller is set to open perimeter air inlets and turn on fans for a set duration of time in five-minute increments.

A typical MV time cycle for day one during brooding might be set to operate fans ON for 30 seconds and OFF for 270 seconds. This ON time is gradually increased as the flock gets older and in-house conditions change, requiring higher rates of ventilation. When in the MV mode, heating systems and ventilation systems often run at the same time. Once the in-house temperature increases above the desired set point the MV fans are called to run continuously based on temperature control and the house is no longer in MV.

The Minimum Ventilation Goal

The goal of MV is to maintain adequate moisture removal and air quality without burning excess fuel or stressing birds in the process. For MV to be successful, the four POST conditions must be met: correct static Pressure to achieve air throw; correct inlet Opening to achieve a high velocity air stream along the ceiling and proper circulation; correct Source of incoming air, so that all air coming into the house enters into and passes through the brood chamber (during brooding); and correct fan run Time for sufficient moisture removal and air quality.

For clarity, the following more detailed explanations of these four requirements refer to an example 40-foot wide house as shown in the illustration below.

Pressure (P): Target Static Pressure

The correct operating pressure for house operation in cold weather MV is related to the width of the house. One rule of thumb to remember is for every 0.01 inches of water column operating pressure, a properly opened vent door should throw the incoming air a distance of about two feet. Incoming air during MV should reach the peak of the ceiling of the house prior to coming into contact with the chicks.

The house in this example is 40 feet wide so a good starting target pressure would be 0.10 inches of water column to get outside air to the ceiling peak. Wider houses pose a problem with getting air to the center peak of the house. Because running more than 0.14 inches of water column is not recommended, circulation fans must be used to supplement the MV system in wide houses to get adequate air mixture.

Opening (O): Number of Vents and Opening Size

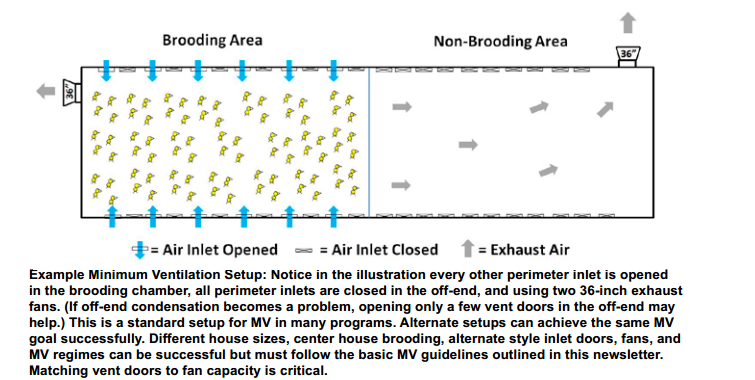

The decision has to be made on the number of perimeter inlet vent doors to use in the MV setup based on the number of fans used. For this example, as a starting point two 36-inch fans are picked for use during MV so the number of vent doors utilized for MV should be compatible with running two 36-inch fans. Many houses are not tight enough to use two 36-inch fans for MV. They will require three 36-inch fans or one 36-inch and one 48-inch fan.

This example house has 50 perimeter inlet doors in the house to run a maximum of four 48-inch fans for maximum power ventilation. Since we are starting MV with only two 36-inch fans it is necessary to latch off 75 per cent of the inlets. This will ensure that the correct number of vents in use will match the cubic feet per minute (cfm) of the fan power used for MV. Trying to use all of the perimeter inlets with two or three 36-inch minimum vent fans is a serious mistake and will result in all inlets being opened insufficiently to achieve a good air stream.

In almost all cases it is necessary to close a large percentage of the vent doors shut during the first week or 10 days of the grow-out. A good starting point, for example, would be to allow about 12 to 14 inlets (about 50 per cent of the inlets in the brooding area) to open and close all of the inlets in the non-brood section. The goal is to get ceiling mounted vent door inlets to open about 1.5 to 2.0 inches or sidewall mounted vent door inlets to open about 2.0 to 2.5 inches during each MV cycle.

These opening sizes are starting point guidelines for basic metal doors. If the vent doors are not opening enough then more vent doors should be closed to make the existing doors open properly. Simple, inexpensive latches can be added to any vent door. Tightening up the house is preferred but turning on an additional fan is another option to achieve proper door opening. If doors are open too much then additional doors must be opened up.

It is highly recommended to use either smoke emitters or orange construction tape to test the incoming air through the vent doors to make sure the air is traveling along the ceiling and to the centre peak of the house. Achieving proper vent door opening and air throw is a critical component in the MV setup.

Source (S) of Air and Number of Fans

Remember that during brooding all incoming air should be drawn through the brood chamber and then be exhausted by the fans. The number of vents in use will match the cfm of fan power used for MV. Air that bypasses the brood chamber does not count as MV air for the chickens and is of no value to the birds. When birds are released to full house, some brood chamber vents will have to be closed and some off-end vents opened for uniform air distribution. Our example house has one 36-inch fan in the brooding chamber and one 36-inch fan in the off-end.

These are typically used as MV fans. These fans will be rated at about 10,000 cfm each for a total of 20,000 cfm for MV. Some houses may use a combination of 36-inch and 48-inch fans for MV based on the size of the house and level of house tightness. The looser the house the more fan power required to achieve proper vent door opening during ventilation cycles.

Time (T): Fan Cycle Time

Finally, the minimum amount of fan cycle time required to run during MV must be calculated. This calculation assumes that all ventilation air passes through the brood chamber. This number is programmed into the controller’s five-minute timer to make the house run regardless of temperature or heat settings in order to remove moisture and improve air quality for the chickens. This on-time number is a starting point and it is not recommended to run less than 30 seconds out of five minutes.

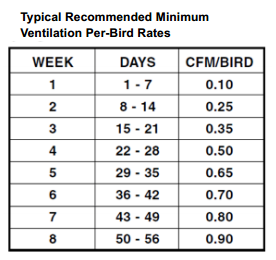

As chicks age and water consumption increases, MV cycle time must also increase or the house conditions and air quality will deteriorate. The addition of fan run time should correlate with the increase in water intake into the house. Knowing the cfm of the MV fans, the number of birds in the house and the age of the birds in weeks, the percentage of timer on-time can be calculated for typical conditions. Example calculations and typical MV per-bird rates are shown below.

Calculating MV Fan Cycle Time

First, calculate the total cfms needed, according to the age of the birds:

Total cfm’s = cfm/bird needed times number of birds in the house

Example: In Week 1, with 0.10cfm per bird needed, and with 24,000 birds in house, 0.10cfm × 24,000 birds = 2,400cfm needed

Percentage of time = cfm needed divided by cfm capacity of fans used (Fan output can vary. Do not overestimate the capacities of your fans.) 2,400 cfm needed divided by 20,000 cfm of MV fans used = 0.12 = 12 per cent 12 per cent × 300 seconds = 36 second ON time.

So 36 seconds ON and 264 seconds OFF would be a good starting point for day one.

Rates shown in the table are ideal MV rates on clean dry bedding. For built-up litter, rates should be increased. ON times must be increased as needed – approximately every three days. These rates are a starting point for MV. Air quality and conditions in the house will dictate if the rate should increase or decrease. Check with company for specifics applicable to your operation. Rates given here are for temperatures from 30 to 60°F.

If in-house humidity levels exceed 65 per cent or ammonia levels exceeding 25ppm are measured, then 15 seconds should be added to the fan cycle time. If in-house humidity drops below 50 per cent or the appearance of dust is noticed, the subtraction of 15 seconds to fan cycle time may be in order. In-house conditions should be monitored early in the morning to inspect each house for indications of a change in the MV programme.

There is a simple MV fan cycle timer calculator located at www.poultryhouse.com that can be downloaded or used directly from the website. Also, there is a smart phone web application that can be used in conjunction with most any smart phone to calculate MV on the go. The link to this web application is: www.ag.auburn.edu/nptc/calc. Please note you must have a moderate phone service and internet signal to run this application on the smart phone. Special instructions for installing and using this mobile web calculator can be found in our YouTube section of our website.

Remember P-O-S-T

Generally, if the guidelines of good static pressure, correct inlet opening, correct source of air and adequate run time are followed, the resulting MV setup should get the producer off to a good start during cold weather. As birds age and deposit increasing amounts of moisture in the house the MV timer setting must increase to keep the litter and air quality in acceptable conditions. The most common mistake we find on farms is the failure to latch designated perimeter vent doors shut during MV. The fans, pressure and fan cycle run time can all be correct, but if all the vent doors are opening only ¼ inch the incoming air is directed straight to the feed and water lines and the results will be less than desirable.

Wet litter and chilled birds are often found in houses where all of the vent doors are left open during MV. While it is fairly easy to make adjustments to this system from the control room, the one main factor that many seem to forget is vent door adjustment. The example house starts out with approximately 25 per cent of the vents opened in the brood chamber. As birds are moved to full house we still need 25 per cent of the vents opened in the house but they must be evenly distributed throughout the house. Vents need to be opened in the off-end and closed in the brood chamber to balance air distribution. As birds age and more fans are added, more vents must be opened to maintain the proper opening and air throw to the ceiling peak.

Bottom Line

Getting the P-O-S-T requirements right enables the grower to maintain the lowest ventilation rates possible to maintain adequate moisture removal and air quality without burning excess fuel or stressing birds in the process. Maintaining proper ventilation during times when the house needs heating may incur slightly increased fuel costs but these are far outweighed by the pay-off from getting top flock performance.

January 2015