Practicing good broiler stockmanship is the key to minimising antibiotic use – Part 1 of 2

The emergence of antibiotic-free (ABF) or minimal-use antibiotic programmes around the world has focused attention on the importance of stockmanship and best-practice management techniques in the broiler houseA good stockman will use all senses – sight, taste, hearing, smell and feel – to stay “in tune” with the birds’ behaviour and comfort level, and in the case of an ABF environment, stockmanship becomes even more important. The stockman must be able to recognise changes in flock behaviour which may indicate a problem that requires prompt corrective action.

Potential performance issues can almost always be identified by daily flock observations, accurate record keeping and regular record/data analysis. An experienced stockman will be aware of the areas where challenges appear during the broiler flock cycle, and what input is required to either prevent or minimise the effect on flock welfare. This article highlights key areas where broiler flock issues can occur, and emphasises the importance of good stockmanship for bird welfare and performance.

Farm hygiene and biosecurity

Biosecurity should be a primary focus for all broiler farms, but this is especially true for flocks grown without antibiotics. Access to the farm should be restricted to essential visitors at all times, and a visitor book should be used to document all personnel and equipment movement onto the farm. Site visitors must comply with visit farm protocols and, where possible, shower in and change into freshly laundered farm clothing. Good stockmen will keep a close eye on farm activity when preparing for chick arrival, and throughout the life of the flock, so that they are aware of, and can limit, potential biosecurity risks.

Thorough cleaning and disinfection of the house, as well as appropriate downtime between cycles (not less than 7 days) is necessary to prevent the carry-over of pathogens from the previous flock. Hot water and effective detergents should be used to ensure any grease or organic material that may be present is completely removed from all surfaces and equipment (Figure 1). After cleaning, disinfection should take place. It is important to ensure that the correct dilution rates for any cleaning and disinfection products are used. Where local legislation permits, formaldehyde treatment can be applied as the final step in the farm hygiene programme. To determine the effectiveness of the cleaning and disinfection procedure, it is good practice to check all internal surfaces and equipment for Total Viable Count (TVC), Salmonella and E. coli, after cleaning and disinfection is complete. Water systems must also be cleaned and sanitised with approved products to remove biofilms. The stockman should walk through the house after cleaning and disinfection to ensure that the correct procedures have been followed and that the house is ready for chick placement.

Figure 1. Internal house cleaning and disinfection

Bedding material can be a source of pathogens in a newly cleaned broiler house. If possible, heat-treated material should be used to eliminate the possibility of introducing health problems to a new flock. Only litter that has been tested or is certified to have a TVC< 10cfu/g should be used in an ABF broiler house.

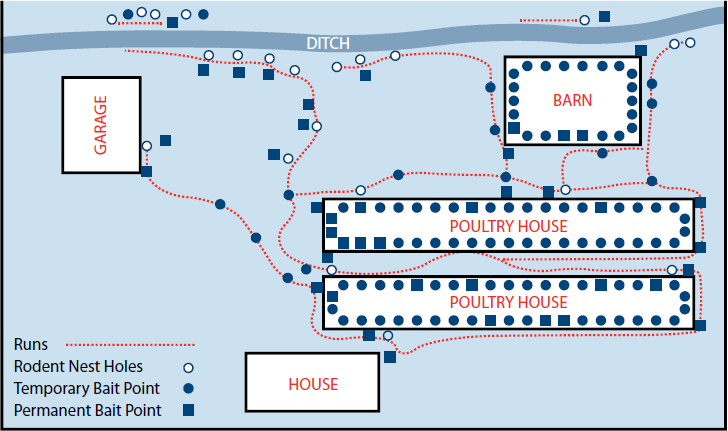

Exterior house areas and concrete walkways should also be cleaned and disinfected. Vegetation around the broiler houses should be cut back and any waste material removed from the site. A good rodent baiting plan (Figure 2) should be in place prior to the arrival of chicks, and rodent bait stations should be checked for activity and re-baited throughout the life of the flock. Walking around the exterior of the broiler house and the larger farm grounds will give the stockman a good idea of where and how potential biosecurity hazards could cause issues for flock welfare.

Figure 2. Example of a good rodent baiting plan

House conditions at chick placement and during brooding

Temperature and relative humidity in relation to chick comfort

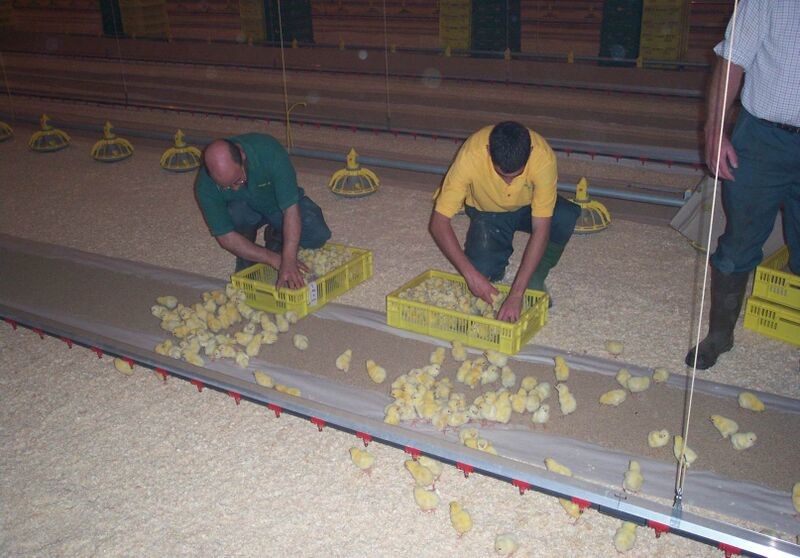

In order to achieve the correct environmental conditions when chicks are placed, houses should be heated to an air temperature of 30C (86F) at least 24 hours prior to chick placement, with the litter temperature being 28 to 30C (82 to 86F). The relative humidity (RH) should be 60 to 70 percent and temperature and RH monitored routinely to ensure a uniform environment. In colder climates, it may be necessary to preheat the house for 36, or even 48 hours, to achieve the correct conditions. Chicks must be delivered to the farm as soon as possible after hatching and be provided with immediate access to feed and water (Figure 3).

Figure 3. Placing chicks

Daily records of temperature and RH must be maintained throughout the life of the flock. These records, combined with daily observations of bird behaviour, can be used to adjust the house environment and ensure the birds are comfortable at all times. This is critical during the early period in the chick’s life (up to 12 to 14 days) when the birds are unable to regulate their body temperature (Figure 4). The stockman will be able to feel the house temperature, as well as listen to the vocalisations of the birds and observe their distribution within the house, to help determine if the chicks are comfortable.

Figure 4. Observing the temperature at floor level is a key factor in determining chick comfort

Ventilation

The correct minimum ventilation rate should be established prior to the chicks being placed. Minimum ventilation supplies adequate fresh air, removes excess moisture, and limits the build-up of potentially harmful gases and airborne by-products. Inadequate minimum ventilation can lead to respiratory challenges later in the flock’s life, which may require antibiotic treatment. No matter what ventilation system is being used (natural or power ventilation), it is important that the correct monitoring is being done to ensure that equipment is operating properly and air quality is being maintained. The stockman should assess the house for adequate ventilation by asking the following questions:

- Are the birds vocalising as normal, or can snicking/sneezing or other respiratory noises be heard?

- Are the fans running properly, or do the bearings sound noisy or the belts sound loose?

- Does the air feel humid, hot or cold?

- Is there enough or too much air speed?

- Does the house smell of ammonia?

The importance of getting a good start

Providing chicks with the correct environmental and brooding conditions will ensure all of their nutritional and physiological requirements are met. Meeting these requirements promotes early development of feeding and drinking behaviour and optimises gut, organ and skeletal development to support body-weight gain and bird health throughout the life of the flock.

Challenges during this early stage of life, caused by inadequate cleaning and disinfection procedures or incorrect house conditions at placement, will impact future bird health, flock performance and uniformity. A poor start will deliver a variable flock later in life, which may have poorer performance and health and be more challenging to manage.

Broiler stockmen have a number of tools at their disposal to monitor brooding conditions and their effect on chick comfort and appetite development, body-weight gain and flock uniformity. These tools include:

Measuring vent temperature. This is an excellent way of determining if environmental conditions are correct for the chicks. In the first 4 to 5 days after hatch, vent temperature should be 39.4 to 40.5C (103 to 105F). Vent temperature should be measured on at least 10 chicks from at least 5 different locations in the house for the first 4 to 5 days after placement (Figure 5).

Figure 5. Measuring vent temperature

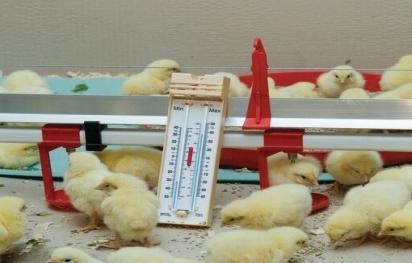

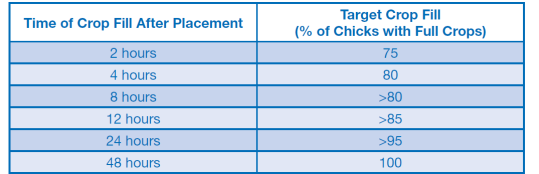

Assessment of crop fill at key times after placement. This is a useful means of determining early appetite development and checking that all chicks have found feed and water. Crop fill (Figure 6) should be monitored during the first 48 hours, but the first 24 hours are the most critical. An initial check two hours after placement will indicate if chicks have found feed and water. Subsequent checks at 8, 12, 24 and 48 hours after arrival on the farm should also be made to assess appetite development (Table 1). Samples of 30 to 40 chicks should be collected at three or four different locations in the house.

Figure 6. Assessing crop fill of chicks with a full, rounded crop (left) and an empty crop (right)

Table 1. Crop fill assessment guidelines

Recording individual body weights. It is good management practice to record individual body weights and determine the co-efficient of variation (CV%) of a sample of chicks at placement and then again at seven days of age. This will allow early flock uniformity and its development through the brooding period to be established, and will also provide an indication of the adequacy of brooding management practices. At day-old, it is recommended to individually weigh all the chicks in one box from each parent stock source flock to determine initial flock uniformity. At 7 days of age a sample of individual weights from 100 chicks should be recorded again. The change in CV% between placement and seven days of age can provide an indication of the effectiveness of the brooding set-up (Table 2).

Table 2. Using change in CV% between placement and 7-days of age to determine the effectiveness of the brooding set-up

Conclusions

Biosecurity, good stockmanship and attention to detail will ensure high levels of bird health and welfare. For the chick, during brooding this involves creating the correct, biosecure environment at placement with regular monitoring of chick behaviour and development. However, it is important that a good start is built upon with best practice management techniques and stockmanship throughout the life of a broiler flock. Part 2 of this article will focus on best practice management techniques after brooding to maintain flock health, welfare and performance.