Six innovative companies shaping the poultry industry

Six companies transforming everything from waste management to lighting and in so doing are helping to set the pace for the industry’s future.Productivity

MimicTec, an Australian startup launched in 2016 by Eleanor Toulmin and Sarah Last, who are in their twenties, has created a device that mimics a mother hen to reduce stress and improve productivity in chicks. It provides heat and encourages chicks to bond with it. Initial testing has found improved feed conversion rates, weight gain and feed and water uptake, as well as reduced negative behaviors. “If they are not using all of that stress to develop stress hormones such as cortisol or corticosteroids, then the little baby chicks can use more of that energy to put on weight more quickly,” Toulmin told the website The Victorian Connection. According to the company their product can save farmers money through reduced feed and maintenance costs and also provide better animal welfare.

Gene editing

Globally about 7 billion male chicks are culled shortly after birth in the egg-production industry each year. The males obviously can’t produce eggs and aren’t the right breed for the broiler industry (they’re slower growing and don’t produce a lot of meat) so they end up either being gassed, asphyxiated or, as is conventional in the US, ground alive. A number of companies have been working on the problem, including the Israeli startup eggXYt. The company is developing technology to identify male chicks in ovo before incubation, which means the male eggs can be rerouted to the food supply, egg producers don’t have to pay employees to sex and cull male chicks and the males won’t be needlessly killed. The technology first implants a genetic identifier into the mother hens that only shows up in male eggs. Scanners are then used to identify the males, allowing hatcheries to only focus on growing out females, according to the website TechCrunch.

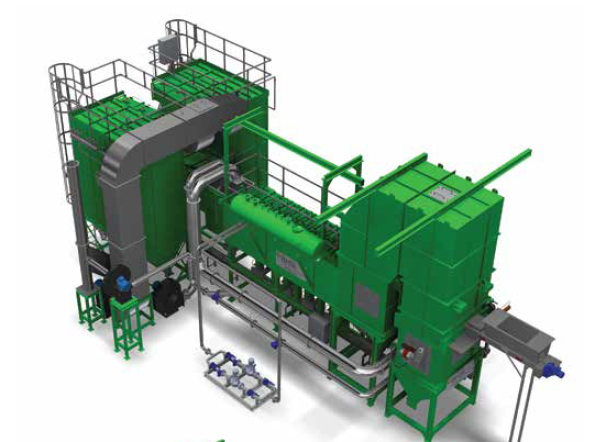

Waste management

Limerick-based BHSL, recently named an Irish Times Innovation Award winner, has developed on-farm technology that converts chicken manure to energy that can be used to heat, cool and provide electricity for the farm. The company’s patented system uses Fluidised Bed Combustion to convert untreated poultry manure into energy with the resulting ash being used for fertiliser. The machines are compact enough to be used on site at farms and are remotely monitored by BHSL from their facilities. “The chicken farmer gets on growing chickens and doing what they do best and we are the energy provider managing that piece of technology delivering heat and other energy to the farm,” Jack O’Connor, the company’s founder and head of research and development, told The Irish Times.

Clean meat

Clean meat, the name given to animal protein grown in labs rather than on farms, has seen a huge influx of capital in the last few years. Memphis Meats, a California company that has created the first lab-grown chicken and duck in the world, has been one of the startups that has benefitted from big-time investments from billionaires like Bill Gates and Richard Branson and the agricultural giant Cargill. Tyson Foods, the US multinational company that’s the second largest chicken producer in the world, is the latest to invest in Memphis Meats. At its most basic, the process of creating meat in the lab involves taking a penny-sized biopsy of stem cells (the kind that can regenerate) from a live animal and feeding the cells various nutrients in an incubator. The cells are tricked into thinking they’re still inside the animal and eventually create enough muscle cells to produce meat. No clean meat has actually gone to market yet, however. The main issue is scaling up production enough to bring costs down. Uma Valeti, co-founder and CEO of Memphis Meats, told me in an interview that when they do enter the market their meat will likely be at a “slight price premium” but as they continue to scale up he’s confident the company will be able to produce meat at a price that is cost competitive with – and ultimately more affordable than –conventionally produced meat. The target date to get products on store shelves is 2021.

Food safety

Launched in 2014 by Mahni Ghorashi and Sasan Amini, who have backgrounds in the genomics field, the Silicon Valley-based Clear Labs is bringing next generation DNA sequencing (NGS) to the food-safety industry. NGS refers to newer methods of DNA sequencing that are faster and cheaper than older processes. NGS provides a greater volume of data with fewer false positives and negatives, according to Ghorashi. The company primarily deals with safety and quality issues ranging from verifying whether an ingredient has been adulterated to preventing salmonella outbreaks, something the poultry industry has to contend with.

“We saw the opportunity to adapt those technologies for applications outside of human health. Food safety was something that intrigued us,” he tells me in a phone interview. “It’s a real-world problem – nearly 50 million Americans get sick each year from food-borne illnesses and thousands die. It’s a significant problem and a huge liability to food companies.” (The US Centers for Disease Control and Prevention peg the numbers at 48 million US citizens who are sickened and 3,000 who die per year.) In the UK, there are about 500,000 cases of food poisoning a year from known pathogens and twice that number when unknown pathogens are taken into account. Companies can store the information NGS provides in databases where “smart algorithms” can be used to mine the data for “predictive and preventive recommendations” that allow food companies to be proactive and preventative, and not just reactive, in regard to potential food-borne outbreaks, says Ghorashi.

Lighting

The Scottish company Greengage Lighting Ltd has created the first ever LED lighting system that uses a patented inductive-power technology similar to that found in an electric toothbrush. This technology allows poultry farmers to easily clip on a range of LED lighting options anywhere along a cable system for customised lighting in poultry barns. Greengage’s Agricultural Lighting Induction System (ALIS) offers a variety of lights geared specifically for laying, breeding and broiler set-ups. “Independent scientific trials prove that our LED lighting provides optimum lighting conditions so that poultry grow consistently to a healthy weight while reducing welfare issues such as aggression, stress and foot sores, as well as stimulating natural behaviour like perching,” Steven Mitchell, Greengage’s marketing manager tells me. The lights are resistant to the disinfectants typically used in the poultry industry, are shatter-proof and energy efficient. This year the company is releasing a line of sensors that monitor temperature, light, humidity, CO2 and ammonia, as well as thermal imaging and acoustic sensors that all can be clipped onto the same ALIS cables as the lights.

This article was originally published in the March 2018 edition of Poultry Digital Magainze