Innovations in Eggshell Quality Evaluation

US - Feed prices are high, profit margins are low, and so now more than ever, we must focus on ways to optimise return on investment, says Diamond V.Eggshell damage is still a major economic loss to the commercial egg industry. By shifting one egg per hen from under-grades to the carton, we can effectively add $0.08 per hen to the bottom line.

All input costs have been expended but when the eggshell is cracked we have lost the offsetting income. Unfortunately, there are multiple factors affecting eggshell quality; genetics of the hen, nutrition and management of feed intake, disease challenge and equipment insult.

There is a long history of methods for evaluating eggshell quality, enabling the producer to isolate and minimize the loss. Many of these have been highly variable and not accessible at the production level. Today, technology delivers to the producer new and innovative devices to document and isolate eggshell problems that go beyond specific gravity evaluation and eggshell thickness. Genetic companies have embraced use of these dynamic eggshell measurements as part of their genetic selection process for several years and now some of this technology is available to the producer.

After a brief review of eggshell quality evaluation techniques, we will conclude with some insightful observations and recommendations from Dr Neil O'Sullivan, Director of Research with Hy-Line International, and a review of currently available technology to augment your quality assurance programmes.

Definition

Eggshell breakage is related to shell quality. The term 'shell quality' is frequently used as a synonym for 'shell strength' and denotes the ability of eggshells to withstand externally applied forces without cracking or breaking (Hamilton et al., 1982).

Historical perspective

In order to improve shell strength, geneticists and nutritionists require techniques to precisely measure large numbers of eggs rapidly and inexpensively. The numerous techniques developed can be divided into two categories: indirect and direct methods. (Hamilton et al., 1982).

Indirect methods

Specific gravity (SG) - Since SG of an egg is related to percent shell (Olsson, 1934) and SG increases, there is a concomitant increase in shell thickness and strength. Data is collected by flotation of egg through a series of ascending SG ranging from 1.060 to 1.104. The SG of the saline solution is the approximate SG of the first floating egg. As the eggs float through subsequent solutions, data are collected, eggs rinsed and used for further evaluation and/or hatching.

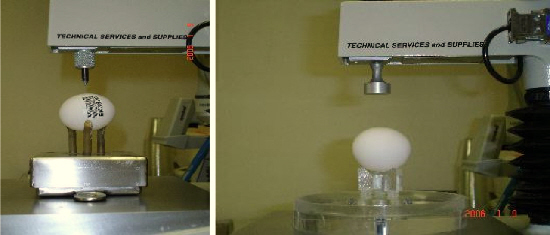

Non-destructive deformation - Deformation is amount an eggshell bends or deflects under an applied force. The slope of the force-deformation line is a measure of shell stiffness. (Voisey and Hunt, 1967a; Voisey and Hamilton, 1975). This method measures the distance an egg deflects when a force is applied to the egg that is less than the force required to break the egg's shell.

Direct methods

Quasi-static compression fracture force - First defined as the compression force required to fracture an eggshell as a measure of it material strength (Hamilton et al 1979b). Contemporary literature describes it as the elastic stiffness properties of the whole eggshell structure. An egg is placed horizontally between two flat parallel steel plates and then compressed at a constant compression speed until a predefined non-destructive load is applied. The slope of the deformation curve is the indicator of the mechanical stiffness of the shell. The mechanical stiffness depends on the thickness of the shell, the curvature, the diameter and the Young's modulus of the material in each layer of the eggshell. (Amer, 1998; Bain, 2006). Eggshell thickness has a major influence on the eggshell deformation during quasi-static compression, (P. Coucke, a).

Impact fracture force - Measures the impact strength of an egg by recording the force on the shell throughout the impact (Voisey and Hunt 1967b).

Puncture force - This procedure has evolved over time and now consists of a constant punch speed and a precise method for recording the applied force. The forces and deformations in the puncture tests are similar in magnitude to those in the compression fracture test but depend on the diameter of the punch. Thus equipment used for the quasi-static compression fracture force can be used to measure puncture force by changing the flat compression head with a punch. (Hamilton 1982).

Factors of interest - Results of non-destructive deformation, compression fracture and impact fracture of eggshells are affected by temperature with an inverse relationship between temperature and shell strength. Voisey et al., 1979b, observed that as temperature decreased from 45 to -5°C, the fracture strength of eggs increased.

Indirect methods are used to measure shell strength on the assumption that the indirect values obtained are correlated with the direct values. However, there is only a moderate relationship between the data from indirect and direct measurement, (Hamilton et al., 1982). Most of these evaluation tools are labour-intensive, slow and subject to environmental influences.

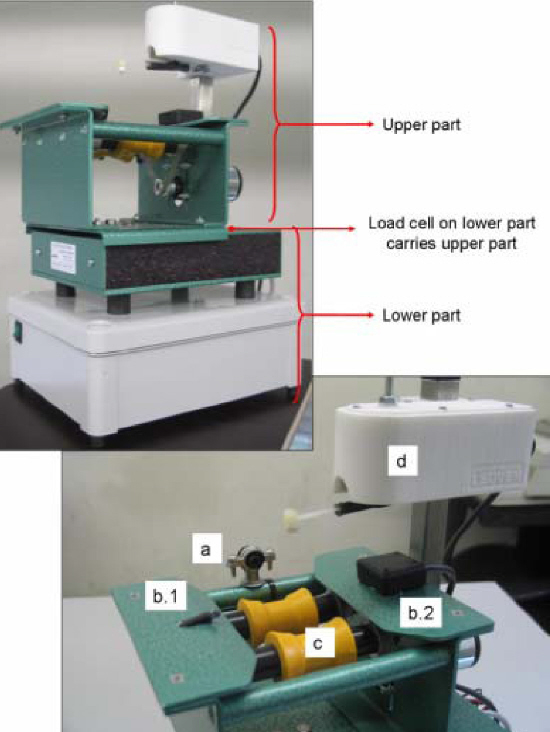

Couch (1998) presented a fast, objective and non-destructive method for determining eggshell strength based on acoustic resonance analysis. This technology measures the resonant frequency (RF) of the egg and its damping ratio (damping ratio = how rapidly the oscillations decay from one bounce to the next).

Further research conducted by Mertens et al. in 2006 concluded that strong eggs (thick shells) with high damping ratios are able to absorb the impact energy, whereas strong eggs with the same shell thickness with low damping ratios are not and they become brittle.

Adapting new technologies: Dynamic method

Eggshell strength determined by the acoustic resonance technique and characterised by the Kdyn and the damping ratio, proves to be an acceptable measure for eggshell quality (Mertens et al., 2006). This process further has a major advantage in the speed of measurement. The total time of the signal response of an egg excited with an impact excitation is 10 to 30ms, depending on the damping properties of the egg. This allows a fast and non-destructive eggshell strength evaluation, which can be applied in real-time conditions of egg grading (P. Coucke.)

Similar work (Hao Lin et al., 2009) concluded that the use of the acoustic resonance technique combined with an appropriate supervised pattern recognition is a promising method to detect cracked eggs.

From a research perspective, Dr O'Sullivan confirmed: "RF methods which give us accurate crack detection, and Kdyn are proving the most robust at improving shell quality. Compression testing and puncture force, both also being useful but less informative than the former methods. Shell thickness and specific gravity (SG) are too crude for the level of precision we need to have, they can only detect gross difference."

What is available for me

Today, we can find this technology in operation in not only the genetic research lab but also in the commercial egg processing setting. A leading commercial egg grading company incorporates this technology as the basis for its cracked egg detection system using a magnetic crack detector in real-time detection. The system relies on small impactors that excite the shell. The amplitude and/or number of rebounds is measured. The process tests the elasticity of the eggshell surface at about 24 to 36 points resulting in excellent crack detection with few false rejects.

Many commercial egg processing locations are now SQF-compliant and many more UEP 5-Star certified. With an increased emphasis on quality control and the resulting additional personnel required, many companies are now interested in establishing their own in-house egg quality evaluation and improvement process.

Current economic pressure further demands that production personnel get more eggs produced into the carton. In-house evaluation of eggshell quality must be completed on the most accurate equipment available if adequate progress is to be made. Genetic companies have long been using and developing new technologies for their egg quality evaluation on highly selected genetic lines to ensure eggshell strength improvement for each subsequent selection.

With guidance from Dr O'Sullivan, Director of Research for Hy-line International, listed below are several shell strength instruments that might be of value in your operation.

Lab Instruments of interest for flock evaluation

Hy-Line International Egg Quality Lab uses the following equipment as part of their ongoing genetic evaluation and selection process:

Diamond V asked Dr O'Sullivan for his recommendation for the commercial egg producer interested in purchasing equipment. "Where would you invest your dollars for the greatest benefit?" His response: "The AET (acoustic egg tester) devices, $8,000, are far better than the devices used for BS (breaking strength) and PS (puncture strength). These cost $25,000 each from TSS in England. The data are not as good as the Kdyn and number of cracks (from the acoustic equipment)."

Diamond V thanks Dr O'Sullivan for inspiring this investigation and sharing his opinions, process and photographs.

Other commercially available options

Sanovo SSSI 110/220 is an instrument for measuring shell strength based on strain gauge technology. When strain gauge contacts the eggshell it decreases speed and slowly builds up a force until the shell cracks. The shell strength is calculated based on the force and the elastic movement on the eggshell before it is cracked.

Sanovo SHCI 110/220 is a three-in-one tester able to automatically calculate the Haugh unit and to measure both the albumen height, yolk colour and egg quality according to standard consumer grades. The test takes 20 seconds.

Sanovo SSTI 110/220 measures eggshell thickness using ultrasonic technology. Ultrasonic waves are applied to the shell and thickness is expressed by the time of flight by the sonics reflected from inside the shell. (Accuracy at ± 0.01mm) www.sanovoeng.com

ORKA Food Technology, Ltd, Egg Force Reader ($8,500-$10,000) Specifications: "Egg Force Reader measures the destruction strength of egg shells and is a direct measure of marketability."

ORKA EggAnalyzer - determines the weight of eggs, albumin height, Haugh units, yolk color and USDS grade for routine quality control and regulatory compliance. (Approximately €5,465.00)

ORKA EggShell Thickness Gauge - uses ultrasound to measure the thickness of shells for quality control and research applications. www.alibaba.com

*Diamond V does not endorse or validate any of the above equipment but is presenting a list of options discussed in the poultry industry trade for review and evaluation.

Full detailed references cited in this investigation can be supplied upon request.

References

Hamilton, R.M.G. 1982. Methods and Factors That Affect the Measurement of Egg Shell Quality. Poultry Science. 61:2022-2039

Olsson, N. 1934. Studies on specific gravity of hen's eggs. A new method for determining the percentage of shell on the hen's eggs. Otto Harrassowitz, Leipzig

Voisey, P.W. and J.R. Hunt. 1967a. Relationship between applied force, deformation of eggshells and fracture force. J. Agric. Eng. Res. 12:1-4.

Voisey, P.W. and R.M.G. Hamilton. 1975. Behavior of egg shell under compression in relation to deformation measurements. Br. Poultry Sci. 16:461-470.

Hamilton, R.M.G., B.K. Thompson and P.W. Voisey. 1979a. The effects of age and strain on the relationships between destructive and non-destructive measurements of eggshell strength of White Leghorn hens. Poultry Sci. 58:1125-1132.

Amer Eissa, A.H. 1998. The engineering factors affecting handling and loss reduction of egg production. Ph.D. thesis, University of Minoufiya, Shibin El-Kom, Egypt.

Bain, M., I.C. Dunn, P.W. Wilson, N. Joseph, B. DeKetelaere, J. De Baerdermaeker and D. Waddington. 2006. Dynamic stiffness: A novel method of determining eggshell quality in domestic hens that predicts the like hood of damage in the field. Br. Poult. Sci. (accepted).

Bell, D. Egg breakage-from the hen to the consumer. Calf. Poultr. Lett. (Apr.):2-6.

Voisey, P.W., R.M.G. Hamilton and B.K. Thompson, 1979b. The effect of temperature on the resistance of the hen's eggshell to fracture under impact and compression and to deformation under non-destructive forces. Poultry Sci. 58:1149-1153.

Coucke, P., G. Jacobs, P. Sas, and J. De Baerdemacker. Comparative Analysis of the Static and Dynamic Mechanical Eggshell Behavior of a Chicken Egg. Flemish Institute for Scientific and Technology Research (I.W.T.) doctoral grant no942019.

Mertens, K., F. Barnelis, B. Kemps, B. Kamers, E. Verhoelst, B. De Kelaere, M. Bain, E. Decuypere and J. De Baerdemaeker, 2006. Monitoring of Eggshell Breakage and Eggshell Strength in Different production Chains of Consumption Eggs. Poult. Sci. 1670-1677.

Hao LIN, Jie-Wen ZHAO, Quan-Sheng CHEN, Jian-Rong CAI, and Ping ZHOU 2009. Eggshell Crack Detection on Acoustic Impulse Response and Supervised Pattern Recognition. Czech J. Food Sci. 27(6):393-402.