Average Hatchery Hatches 164,000 Chicks More by Using BioStreamer™ Re-Store

GLOBAL - By using heat treatment during storage, an average commercial hatchery gains 164,000 chicks per year.These chicks are born within a shorter hatch window, are more uniform and of better quality. It also makes the logistic organisation within the hatchery easier.

Restore the fertility of stored eggs

‘Lots of hatchery owners do not know they lose easily more than 0.5% of their chicks due to egg storage losses. Or that 0.2% of all the eggs that are classified as infertile, are fertile in reality and that it is possible to turn these embryos into healthy chicks,’ says Roger Banwell, Hatchery Development Specialist at Petersime. Egg storage times in hatcheries are often unavoidable because of logistics, markets conditions, variable order sizes, etc. Storing eggs for longer than three days, however, leads to losses of fertile eggs, less uniform chicks and extra logistic workload. The longer the storage times, the more hatchability and chick quality decrease and the longer incubation time gets.

Petersime has developed the long-awaited answer to this problem: the BioStreamer™ Re-Store. The Re-Store machine warms up the eggs for short periods of time during storage, restoring a significant part of the hatch decrease you normally would have lost. In an average hatchery, Re-Storing eggs leads to more chicks hatching, a narrower hatch window, more uniform chicks and easier logistics.

.jpg)

“We have been using Re-Store now for one month. Hatchability is significantly higher, chick quality is visibly better, mortality is lower, we have less second grade chicks and the hatch window has shortened. I definitely recommend it. It makes a difference, most of all with eggs from a young flock.” Mr Marian Foltyn, Incubation Manager, Výkrm Třebíč, Czech Republic

164,000 more chicks hatching in average hatchery

An average commercial hatchery processing one million eggs per week, has 164,000 more hatched day-old chicks per year than the same hatchery that does not use Re-Store. The longer the eggs are stored, the bigger the gains. Why? Professor Eddy Decuypere from the University of Leuven, explains: ‘In the egg holding room, eggs are kept at or under a so-called threshold temperature of physiological zero for development. However, some partial, but not a global or proportionate development can take place at these subthreshold temperatures. Different cells or tissues in these early embryos may have different threshold temperatures for development, resulting in uneven or disproportionate development. If this disproportionate development progresses too far, it may interfere with embryonic viability and hence also hatchability.’

In nature, a mother hen will lay one egg every day, until her nest is complete. As a result, the older eggs will be warmed each time the hen returns to her nest to lay the next egg. These eggs thus undergo a short period of incubation every day. Professor Decuypere continues: ‘Periodic warming during prolonged storage allows the embryo to redress disproportionate development and ensures the required degree of embryonic development for all tissues in a proportional way.’

Following extensive research using accurate measuring systems such as OvoScan™ and with the cooperation of Aviagen Hilbersdorf, one of the world’s largest parent stock hatcheries, Petersime developed a heat treatment system that has proved to sustain the number of in fertile eggs during storage: BioStreamer™ Re-Store. In other words, Re-Store recovers early embryonic mortality and restores the fertility of eggs, gaining 0.3% to 3% extra day-old chicks per year.

.jpg)

Fig.1. With Re-Store, you hatch 0.3% to 3% more day-old chicks per year

More uniform chicks

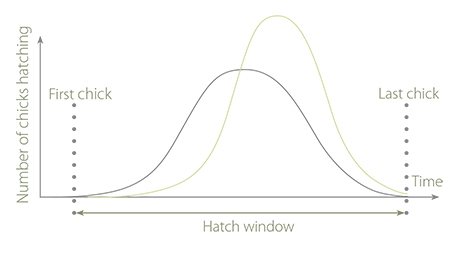

More uniformity during incubation and after hatch is another positive effect of Re-Storing the eggs. Before storage, every embryo will be in a slightly different developmental stage. Some are more robust against storage than others. Re-Store will align the embryonic development (see figure 1. above). The result is a better synchronisation of embryos right from the start, which leads to a narrower hatch window and more uniform chicks.

Fig. 2. Heat treatment during storage aligns embryonic development and makes the eggs more robust against storage

Fig. 3. Re-Storing eggs narrows the hatch window and makes chicks more uniform

Easier production logistics

Next to increasing the fertility of stored eggs and the uniformity, Re-Store makes logistics easier. Traditionally, different storage times require different incubation times. The hatchery manager needs to set some machines two hours earlier, others one hour later… This is not easy to organize and quite time-consuming to execute. Whereas with Re-Store, you do not need to apply different timings for different storage times anymore. To boot, planning when the personnel should come to help with chick handling, is easier to organize thanks to the narrower hatch window.

I clearly notice the difference between the hatchery’s results before we started using the BioStreamer™ Re-Store and after,’says Mr Marian Foltyn, Incubation Manager at Výkrm Třebíč. ‘We now put all eggs that arrive from the farm in our Re-Store machine. I would recommend Re-Storing the fertility of your eggs to any other hatchery, whether they are in the broiler, layer or grandparent business.’

The broiler hatchery Výkrm Třebíč is located in the Czech Republic. This high-capacity hatchery was designed by Petersime, who also supplied all HVAC equipment, BioStreamer™ incubators, Embryo-Response Incubation™ technologies and BioStreamer™ Re-Store machines. It was built in 2013 as part of the vertical integration strategy of Agrofert, the holding above Výkrm Třebíč, to control the entire production cycle from hatching to slaughter. Výkrm Třebíč handles more than 40 million eggs per year.