How to Increase Hatchability with 2%

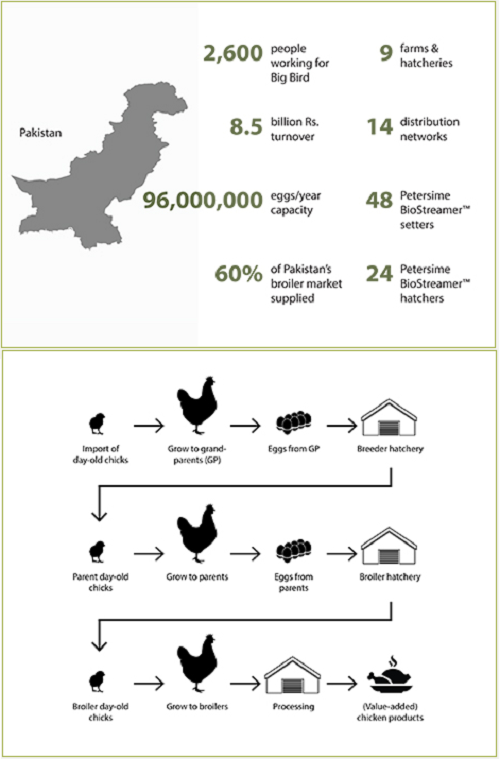

GLOBAL - Petersime asked Dr Iftikhar, Hatchery Manager at Big Bird, to share his company’s experiences with raising the hatchability of day-old chicks with 2 to 2.5%. He also passes on some tips for fellow hatchery managers.Big Bird is one of the major suppliers of poultry in Pakistan. Its vertically integrated structure stretches from growing Hubbard Grandparent (GP) stocks to Parents down to broilers and supplying value-added chicken products. Thanks to the adherence to quality, Big Bird made a name in Pakistan and the international market for their hatching eggs and day-old chicks. It represents one of the most modern integrated poultry breeding systems in the country.

When one of the former hatcheries of Big Bird was renovated into a modern breeder hatchery, the lay-out, procedures and equipment were changed. The result: an increase in the hatchability rate of day-old chicks with 2 to 2.5%. We spoke with Dr Iftikhar, Hatchery Manager at Big Bird Poultry Breeders. He has been working in incubation since 18 years, starting in a GP operation of Big Bird and now in charge of the hatchery management in the breeder hatchery that hatched up to 2.5% more chicks than before.

What did you change to increase the hatchability rate with 2 to 2.5%?

Dr Iftikhar: “On the basis of the results of Petersime Incubators, we decided to make a new state-of-the-art broiler hatchery in Pakistan. All these changes combined delivered fantastic results: the hatchability rate increased with 2% to 2.5%, which is really remarkable.

We implemented quite some changes to the lay-out of the hatchery, the working procedures and the incubators. First and foremost, we changed the design of the hatchery with the help of Petersime. The Project Engineering team of Petersime has extraordinary design expertise, from which we, as a customer, benefited greatly. Every step, from receiving the eggs to the transport of the hatched chicks, was made more efficient and bio-secure. Clean and dirty areas got separated strictly. Fresh air was supplied all over the hatchery and properly exhausted afterwards to make sure all the vital areas received uncontaminated, clean air. The efficiency and bio-security increased.

Furthermore, we dedicated even more attention to sanitation, cleaning and handling of birds than before. We altered the vigilance and people coming in and out were checked thoroughly to make sure our bio-security levels were uncompromised at all times.”

What advice would you like to share with fellow hatchery managers to increase the hatchability rate?

Dr. Iftikhar:

- “I would say that the most important aspect that deserves your full attention is the design of your hatchery. It can have a big impact on your results. Keep your clean and dirty areas as strictly separated as possible.

- Keep your equipment well maintained.

- Train your staff. I followed Petersime’s Hatchery Management Training twice and each time I applied the maximum of the skills and knowledge I gained during the training.

- Monitor the running of your machines constantly. Keep track of how the incubators are performing. All of these efforts can have a big impact on your incubation results.”

Special thanks for the interview to Dr Iftikhar, Hatchery Manager at Big Bird (http://www.bigbirdgroup.com.pk), and Ms Saeed, CEO of Golden Harvest and distributor of Petersime equipment (http://www.goldenharvest.com.pk).