EU Regulation Changes View on Stunning at Slaughter

A basic requirement for humane slaughter of animals, including poultry, is that they should be stunned before slaughter by exsanguination, writes Editor-in-Chief, Chris Harris.Under commercial conditions, red meat animals, including ruminants and pigs, are stunned using either a penetrating captive bolt, non-penetrating concussion bolt, electric current or carbon dioxide gas; poultry species are most commonly stunned using electrified water bath.

According to E. Lambooij and M.A. Gerritzen from the Animal Sciences Group at Wageningen UR in the Netherlands, there are two main reasons for using the water bath system. Firstly, it may be difficult to apply captive or concussion bolt owing to a very small target area (head) for shooting in poultry without compromising bird welfare under commercial conditions. Secondly, the throughput rates required in medium to large chicken processing plants, killing 5,000 to 9,000 birds an hour, can be easily achieved with water bath stunners rather than with captive bolt or concussion stunners.

However, there are now other systems of stunning that over the years have been introduced into the poultry processing plant and are now becoming more popular because of their greater welfare credentials.

One alternative stunning system to the electrical water bath stunner for broiler chickens is gas stunning (CAS = Controlled Atmosphere Stunning).

Another method is low atmospheric pressure stunning (LAPS), which recent studies have claimed is the most humane stunning system.

Both the use of controlled atmosphere stunning and low atmospheric pressure stunning can eliminate the stress associated with decrating and/or shackling of live birds prior to electrical stunning.

Electrical and gas stunning is generally used to induce unconsciousness during cutting and bleeding for reasons of animal welfare in the EU or to induce immobilisation to facilitate automatic neck cutting in the USA.

New EU Welfare Regulation

In the European Union, where annually several billion birds are killed in slaughterhouses and an estimated 330 million day-old chicks in hatcheries, a new regulation to protect animals at the time of slaughter was introduced at the beginning of the year.

The regulation stipulates that each operator has to know what they are doing through the use of a standard operating procedure. Such methodology is not new for slaughterhouses as it is already required and in place for food safety in the Hazard Analysis Critical Control Point (HACCP) system. However, it is new to require standardised procedures for animal welfare.

Operators are required to evaluate the efficiency of their stunning method through animal based indicators. As a consequence, stunned animals have to be regularly monitored to ensure that they do not regain consciousness before slaughter.

Each slaughterhouse has to appoint an Animal Welfare Officer, who is accountable for implementing the animal welfare measures although this does not replace the official inspection and there is derogation for small slaughterhouses.

The regulation also requires manufacturers of stunning equipment to provide instructions on the use of their equipment, on how to monitor their efficiency and keep them in order.

The staff handling animals in slaughterhouses has to be trained and to gain a certificate of competence regarding the welfare aspects of their tasks.

The regulation also aims at scientific support animal welfare to provide technical assistance for officials working in slaughterhouses.

The regulation also covers culling animals for disease control.

The European Commission said that it did not ban the traditional electrified water bath stunner, despite its welfare disadvantages, because of the lack of practical alternatives under certain conditions.

In the case of the water bath for poultry, the alternatives that exist such as the use of gas are presently not developed for the small or medium size slaughterhouses, which represent a very important proportion of the total slaughter capacity in Europe.

The regulation foresees that the Commission will present a report on the possible alternative for stunning poultry at the latest four years after the current regulation came into force.

Similarly, the Commission said that the use of carbon dioxide cannot be rejected at present as there is no commercially viable alternative for certain species like pigs or fur animals and it is a still an important technique for the mass killing of poultry.

Water Bath Stunning

The most common way of stunning poultry with the use of a water bath involves the birds being hung by the legs from shackles and stunning is done electrically by immersion of the head and neck of the bird in an electrified water bath

The most common way of stunning poultry with the use of a water bath involves the birds being hung by the legs from shackles and stunning is done electrically by immersion of the head and neck of the bird in an electrified water bath

In a water bath, in which electrical current is applied to the whole body, a minimum current of 120mA (50Hz) per bird is recommended to induce unconsciousness and a cardiac arrest.

A heart failure is recordable on an ECG (electro-cardiogram).

Lambooij and Gerritzen explain that “as in the brain, in the heart the neuronal interactions are integrated and orderly. Disorder is initiated by direct stimulation by electric current and the heart will fibrillate or stop. The heart failure results in loss of blood pressure and lack of oxygen to the brain and affects the characteristics of general epileptiform insult”.

The EU-recommended minimum current for broilers of 120mA increases quality defects (haemorrhages, broken bones) of carcasses and meat.

The most common electrical stunning method for livestock uses a 50Hz alternating current (AC) with sinusoidal waveform.

According to the Wageningen study, at present a variety of wave forms and frequencies of currents can be supplied. Alternatives for the sinusoidal AC current are pulsed direct and pulsed alternating currents.

“The depth and duration of unconsciousness induced by the electrical stunning is determined by the duration for which the current stays at the minimum level within each cycle (RMS-current, duty cycle, AC/DC),” the study says.

“Due to the frequency in relation to wave form and current immobilisation, sleep, anaesthesia, stunning and convulsive (therapy) can be induced Stimulation of the cortex and brain stem using 50 to 300 pulses per second may introduce desynchronised sleep.

“Anaesthesia may be induced by stimulation with 100 to 100,000cps using a duration of 3ms and 18mA. Spasms, irregular breathing and cardiac arrhythmia were induced with a longer duration or a higher current. Irregular rectangular pulse currents may decrease the muscular spasm(s).

“Stunning of slaughter animals is based on inducing a grand mal seizure or general epileptiform insult. A DC constant current is introduced to immobilise animals to treat them and a 50Hz low current is used to immobilise broilers for automatic cutting for bleeding.”

| Minimal required current (mA per animal) in a water bath stunner Frequency (Hz) | Broiler | Turkey |

| < 200 Hz | 100 | 250 |

| 200-400 Hz | 150 | 400 |

| 400-1500 Hz | 200 | 400 |

The most effective current is 50 to 200Hz.

According to the poultry processing equipment manufacturer, Meyn, “in the conventional water bath stunner, the birds are hung in the shackles of the overhead conveyor by their feet and their heads pass through the water bath. Electrodes in the water bath and the shackle guide deliver the stunning shock as the bird’s head enters the water, effectively completing an electrical circuit.

“The main advantage of high frequency stunning (over 50 or 60Hz) is that the electric current at this frequency tends to run along the surface of the birds. This decreases the number of haemorrhages, largely reducing possible damage to the birds and thus benefiting meat quality.”

Gas Stunning

At present, the gas mixtures that can be used for stunning poultry in different plants under commercial conditions are:

- 90 per cent argon (Ar) in air

- 30 per cent carbon dioxide (CO2) and 60 per cent Ar in air and 40 per cent carbon dioxide and

- 30 per cent oxygen (O2) and 30 per cent nitrogen (N2).

Ar can be easily administered in gas stunning, because it is heavier than air as is carbon dioxide, tasteless and odourless. Another option is a low concentration of carbon dioxide in Ar. Both these mixtures caused a rapid loss of brain function in chickens, turkeys and pigs.

The Wageningen study says that controlled atmosphere stunning includes several variations of gas mixtures given to induce an anaesthetic state. One method of multi-phase CAS is to unload the birds out of the crate on a conveyor belt and subject the birds to an atmosphere of 30 per cent oxygen, 40 per cent carbon dioxide and 30 per cent nitrogen for one minute to stun them followed by an atmosphere of 80 per cent carbon dioxide and five per cent oxygen for two minutes to kill them.

Another approach of CAS involves exposure of poultry while remaining in the crates in a chamber to a mixture of inert gasses to produce anoxic loss of consciousness. The current UK legislation allows the flexibility of killing with a number of different gasses by anoxia with the carbon dioxide content limited to 30 per cent and oxygen maximised by two per cent.

Carbon dioxide is an anaesthetic gas, which produces rapid unconsciousness when inhaled at high concentrations, however, signs of asphyxia and behavioural excitation are seen because of hypercapnia and hypoxia.

Carbon dioxide is an acidic gas and has been found to be painful, causing unpleasant sensations on the nasal mucosa, lips and forehead in human subjects, when gas puffed stimuli are administered in concentrations over 65 per cent.

“It is likely that an avoidance response is mediated by the olfactory system in birds. It is suggested that carbon dioxide has aversive properties, particularly when inhaled at high concentrations. This has complications for the levels of carbon dioxide to which conscious birds should be exposed during CAS,” says the report.

“Exposure of birds to 90 per cent argon in air or 60 per cent argon / 30 per cent carbon dioxide in air results in an anoxic condition. Under these conditions depression of activity in the brain extends progressively from the telencephalon to the diencephalon and then to the mesencephalon. Anoxia results in suppression of the rostral reticular formation and therefore loss of consciousness and in suppression of the caudal reticular formation and therefore onset of convulsions. Wing flapping is observed before the onset of loss of posture when exposed to argon or argon/carbon dioxide gas mixtures.

“This pointed to the suggestion that wing flapping during immersion in the gas might be a response to an anoxic condition. This may be supported by a study of physiological and behavioural responses in adult hens and chicks.

“When subjected to decreasing oxygen concentration, adult birds slowly became unconscious, without showing any signs of distress, until respiratory failure supervened. Chicks showed similar results but loss of motor control was observed while still conscious, which might cause distress.”

The advantages of the controlled atmosphere stunning system are that it does away with the need to shackle live birds and this reduces the number of broken bones and blood spots in the flesh.

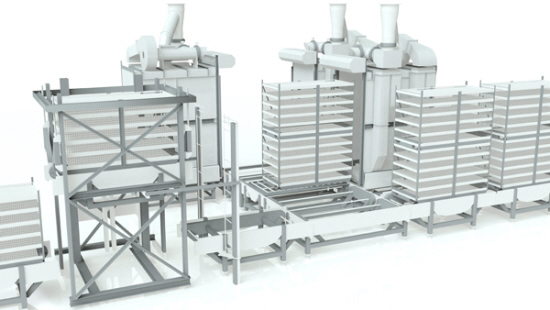

The equipment manufacturer Meyn, Multistage carbon dioxide stunning system, which was installed in the Productos Florida poultry processing plant in Spain late last year allows the birds to be stunned without having to be removed from the containers in which they arrive at the processing plant.

The handling and transport of active birds is taken out of the equation improving welfare and reducing the risk of injury to the bird. This, in turn, improved the meat quality and yield.

Meyn: multistage CO2 stunning system

Low Atmospheric Pressure Stunning

Low atmospheric pressure stunning (LAPS) has the potential to improve the welfare of poultry at slaughter by gradually inducing unconsciousness without distress, eliminating the stress of shackling and ensuring that every bird is adequately stunned prior to exsanguination.

In LAPS, poultry are rendered unconscious just prior to slaughter by gradually reducing oxygen tension in the atmosphere.

Researchers found that, based on EEG analysis, a conservative estimate of the time to loss of consciousness during the application of LAPS was 40 seconds.

During this period the researchers noted an increase in slow-wave (delta) brain activity, consistent with a gradual loss of consciousness.

The increase in delta wave activity began within 10 seconds of beginning LAPS and continued after that.

Delta wave activity peaked at 30 seconds into LAPS, at which point it was consistent with the EEG signals of birds under surgical levels of anaesthesia.

From the ECG analysis, the researchers found that, during the application of LAPS, the birds’ heart rates consistently decreased. They found no instances in which heart rates increased during the period when the birds were potentially conscious. They also observed no behavioural responses that would suggest aversion to the LAPS process.

The system that has been developed by TechnoCatch has been trialled at poultry processor in Arkansas.

TechnoCatch: LAPS system

Mechanical Stunning

Captive bolt stunning is rarely used in the poultry sector because of a lack of means to prevent post-stun convulsions and the precision and speed of implementation that is needed in the process.

Captive bolt stunning is generally used more frequently in a casualty environment to dispatch injured birds, but it can be used in small scale operations for larger birds such as ducks, geese and turkeys. Stunning equipment, such as the Accles and Shelvoke CASH Poultry Killer (pictured right), suitable for chickens, turkeys, ducks and geese, has a fast to operate high bolt velocity generally for use on-farm.

Captive bolt stunning is generally used more frequently in a casualty environment to dispatch injured birds, but it can be used in small scale operations for larger birds such as ducks, geese and turkeys. Stunning equipment, such as the Accles and Shelvoke CASH Poultry Killer (pictured right), suitable for chickens, turkeys, ducks and geese, has a fast to operate high bolt velocity generally for use on-farm.

The tool is designed to apply a powerful blow to the bird’s head, killing it outright, helping to solve many of the animal welfare problems associated with despatching birds by neck dislocation and decapitation.

Accles and Shelvoke say that, as with other procedures applied to birds, casualty slaughter usually requires some form of physical control over the bird. Suitable control is required to minimise pain and distress of the procedure, to assure safety of the person performing the task and importantly to ensure accurate positioning of the instrument.

In the event of the tool being used for the commercial slaughter of poultry then, to comply with current legislation, it must be followed by bleeding or neck dislocation.

A captive needle stunning method for broilers has been developed, in which air pressure is injected into the brain and partly directed to the spinal cord, which may prevent the convulsions.

In broilers, the air pressure stunning reduced post-stun convulsions to less than 13 per cent of the level of convulsions.

The captive bolt stunning method for broilers has been modified, in which air pressure was used to block post stun convulsions. To improve the method for practical application, a commercial air tacker was modified.

A trigger starts the injection of compressed atmospheric air when the needles penetrate the skull, and the duration of air injection was electronically controlled.

July 2013