Investigating Hatchery Practice - Appendices

In the final article in this series, Dr Steve Tullett, consultant for Aviagen specialising in incubation and fertility, offers tips on egg collection, selection, disinfection. fumigation and storage. It forms part of a recently published Ross Tech publication, Investigating Hatchery Practice.Appendix 1. Some Rules of Egg Collection

- Wash hands before collecting eggs.

- Collect eggs at least three times a day – the more frequently eggs are collected, the better the hatchability.

- Collect clean nest eggs first, without touching any dirty, cracked or floor eggs.

- Collect the dirty nest eggs, cracked eggs and floor eggs separately.

- Do not put floor eggs into nests to make them easier to collect later, you will only contaminate the nests.

- Remove any dirt and faecal material from the nest and dispose of it onto the floor litter.

- Top up the nest material regularly or, if using nest pads, remove clean and disinfect the pads regularly.

- Clearly identify the naturally clean nest eggs for the hatchery.

- If dirty eggs and floor eggs are sent to the hatchery, they should be clearly identified and segregated from the clean eggs so the hatchery can set them in a separate setter or in the bottom trays on a trolley or rack – so if they do explode they cannot contaminate clean eggs below them.

- Cool eggs to below 24°C (75.2°F) within four hours of collection and continue cooling until the optimum storage temperature for the expected egg age at set is achieved.

Appendix 2. Some Rules of Egg Selection

The best eggs for the hatchery are those that are naturally clean, a good oval egg shape and collected from clean nests. When the breeder farm and hatchery are short of eggs then anything which is roughly egg-shaped may be considered worthy of setting. However, be aware that:

- Small and large eggs do not hatch as well as medium-sized eggs.

- Round eggs tend to hatch less well than oval shaped eggs.

- Dirty eggs and floor eggs will hatch less well than naturally clean nest eggs and may spread contamination in the hatchery.

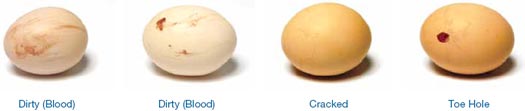

Pictured below are some eggs that may cause problems and should be considered for rejection:

Appendix 3. Some Rules of Egg Disinfection

- Disinfect egg shells as soon as possible after collection.

- Dry methods are preferable, e.g. fumigation, UV light or ozone.

- Fumigation using formaldehyde gas is the preferred and proven method but may not be allowed in some regions.

- If wetting eggs by spraying or fogging make sure:

- The products are designed for use with hatching eggs, i.e. they will not react with the cuticle or be left as a deposit on the eggshell that may interfere with gas or water exchange across the eggshell.

- The solution is warmer than the eggs – otherwise, the contraction of the egg contents may pull the solution and microbes across the shell and cause the eggs to rot and explode.

- The concentration of disinfectant is appropriate – follow the manufacturer's recommendations.

- If washing or dipping eggs, follow the advice above and keep checking the disinfectant concentration is being maintained. Replenish the solution frequently. Only soiled eggs should be washed.

- Wet eggs should be allowed to dry before they are placed in the egg store.

- Avoid scraping or sanding of the eggshell surface – you can compact the cuticle into the pores and reduce embryo metabolism and growth.

- Avoid using cloths to clean eggs because they quickly become contaminated and will only serve to spread the contamination to other eggs.

- Monitor eggs when moving them from a cold egg store into a warmer environment to make sure condensation does not form on the shell surface. If eggs are sweating do not fumigate them and do not put them into a cold egg store until they are dry.

Appendix 4. Some Rules of Fumigation

- Observe local legislation concerning operator safety.

- Use 43 ml formalin (37.5 per cent) and 21 g (0.7 oz) potassium permanganate OR heat 10 g (0.4 oz) paraformaldehyde prills per cubic metre of fumigation room.

- Ensure temperature is >24°C (75.2°F) and humidity is >60 per cent RH.

- Ensure room is well sealed during fumigation and allow at least 20 minutes for the gas to circulate after it has been generated.

- Make sure eggs are well separated on plastic trays and that the fumigant gas can easily penetrate between them.

- Run a circulating fan during fumigation to help circulate the fumigant gas between the eggs.

If any of these conditions are not met, the efficiency of the fumigation will be reduced.

Appendix 5. Some Rules of Egg Storage

- Never put wet eggs (from spraying, washing or dipping) into the egg store. Allow them to dry thoroughly first.

- Eggs benefit from a period of rest after transportation.

- Do not set eggs on arrival at the hatchery, allow them to settle in the egg store for 24 hours.

- Egg store should be well insulated and the door should be kept closed as much as possible.

- Direct the air from inlets and air coolers away from the eggs.

- Take care that the humidification system does not wet the eggs.

- Ceiling fans help provide a gentle air movement through the eggs and will reduce spatial variation in temperature in large egg stores.

- Use the appropriate temperature, humidity and pre-warming depending on the period the eggs are predicted to remain in store before setting:

| Storage period (days) |

Temperature of store °C (°F) |

Humidity (% RH) | Pre-warming at 23°C (73°F) (hours) |

|---|---|---|---|

| 1-3 | 20-23 (68-73) | 75 | n/a |

| 4-7 | 15-18 (59-64) | 75 | 8 |

| >7 | 12-15 (54-59) | 80 | 12 |

| >13 | 12 (54) | 80 | 18 |

- Eggs which have been stored at 12°C (54°F) are liable to sweat (moisture on eggshell from condensation) if not given a short time at an intermediate temperature before pre-warming. See Dew Point or Condensation Table (Appendix 6).

- Stored eggs take longer to hatch (about one hour per day of storage) and hatchability will be reduced.

Appendix 6. Dew Point or Condensation Table

When eggs are moved from a cold environment into warmer, more humid conditions, they may sweat. The following table gives the shell temperature that will result in condensation when moving eggs into a wide variety of temperatures and humidities.

Eggs may sweat when they are transported from a cold egg store on the farm to a warm hatchery or from a cold egg store in the hatchery for pre-warming or incubation.

If eggs are sweating, do not fumigate them and do not put them into a cold egg store until they are dry.

| Relative humidity (% RH) | ||||||

|---|---|---|---|---|---|---|

| Temperature °C (°F) |

40 | 50 | 60 | 70 | 80 | 90 |

| 15 (59) | 11 | 13 | ||||

| 20 (68) | 12 | 14 | 16 | 18 | ||

| Pre-warming 23 (74) |

12 | 15 | 17 | 19 | 21 | |

| 25 (77) | 10 | 13 | 16 | 19 | 21 | 23 |

| 30 (86) | 14 | 18 | 21 | 24 | 26 | 28 |

| 35 (95) | 18 | 21 | 25 | 28 | 31 | 33 |

| Incubator | 21 | 25 | 28 | 31 | 34 | 36 |

| 40 (104) | 23 | 27 | 30 | 33 | 36 | 38 |

To avoid condensation, the egg shell temperature needs to be higher than given in the table.

Appendix 7. Some Suggestions for Hatchery Recording Forms

For examples of forms useful for hatchery recording, click here (PDF file):

- Form 1. Breakout of Unincubated Eggs

- Form 2. Break-out of Partially Incubated Eggs

- Form 3. Transfer Candling Analysis

- Form 4. Transfer Candling Analysis (Simplified Version)

- Form 5. Hatch Debris Analysis

- Form 6. Hatch Debris Analysis (Simplified Version)

- Form 7. Egg Weights and Chick Weights

Further Reading

| - | You can see other articles in this series Investigating Hatchery Practice by clicking here. |

March 2010