Application of pneumovirus vaccine via coarse spray in turkeys

In this article we will discuss vaccinating turkeys by coarse spray, focusing on the interpretation of data to help us make decisions on the correct application, in order to make our vaccination programme effective.Turkey rhinotracheitis is the most important viral respiratory disease among turkeys. The main issue is that the destruction of the respiratory epithelium of the upper respiratory tract “locally immunodepresses” our turkeys, destroying the first defensive barrier, the ciliated epithelium. Consequently, it can cause of 50-100% morbidity, a mortality rate of 80%, as well as from high condemnation rates and, among turkey breeder hens, it can cause a drop in egg production of 30%.

Why coarse spray?

Since eye drop vaccination is the best way to obtain uniform immunity without reverse reaction, we should consider coarse spray as a massive eye drop vaccination, because the purpose is to give local immunity in the target tissue for TRT.

Ciliated cells of respiratory epithelia are thought to be the main target cells for TRT replication. With this local immunity we can have respiratory protection because there will be competitive exclusion and cell-mediated immunity.

To accomplish this, a specific drop size is needed which should be between 170 and 200 microns. In this way, we can ensure that the drop reaches the infraorbital sinus and consequently, we will achieve immunity for 6 to 9 weeks.

The most decisive factor for correct and safe application using this method is the drop size. Each vaccine and each bird (depending on age) requires different drop sizes, with finer droplets having a greater capacity for penetration while coarser droplets will remain lodged in the upper respiratory tract. In this case, for turkeys, we need a drop size of 170-200 in order to achieve effective vaccination. The main factors that determine droplet size are pressure and nozzle size. However, the size of the drop that reaches the bird can be modified according to the temperature, relative humidity, air speed etc.

It is important to maintain a constant pressure in order to have homogeneous drops. At least two bars are needed to make the drop size in question. Once we have control of the pressure then it’s time to choose the proper nozzle for the device. So, nozzles don´t always make the same size droplets. In fact, they produce drops of different sizes, although the vast majority are in the range we are interested in, drawing a Gaussian bell Drops that are smaller go deeper into the respiratory tract but, since this is a small percentage, they don’t produce a reaction. Speaking about environmental conditions, there are no concrete parameters, but it is recommended that extreme temperatures should be avoided. Also, the vaccination water should be between 16 and 27ºC so that it does not affect the vaccine.

Before the application of the vaccine, there are some factors that we need to take attend to:

- storage and transportation

- animals

- medical device

- vaccine preparation and

- poultry house environment.

The temperature shown for proper storage and preservation is between 2 and 8 ºC. Temperatures above or below this range are equally detrimental to the vaccine. Also, vaccines should be stored away from light.

And it is recommended that vaccines are stored in an organized way so as to facilitate identification and avoid confusion.

The ideal healthy animals to vaccinate are non-stressed ones. To achieve this, turkeys should have a clean appearance, normal activity and uniformity of the flock. Adequate faeces are a good indicator of gut health, which is also related to the bird’s immunity.

Most importantly, the respiratory tract should be in good condition, without the presence of mucus, fever or coughs, which would indicate damage to the trachea. This could mean that we are already too late, and the animals could be unprotected.

Special care must be taken with the medical device and treatment. It should not be a simple backpack but the tool through which we protect our turkeys. A good habit is to calibrate the flow frequently. For this, the ideal thing is to use a measuring container. Also, fully charge the batteries before use. If possible, keep 2 batteries ready for each vaccination kit used.

Before starting, wash the tank completely with distilled water and when vaccination is over, clean the complete circuit. To reduce the possibility of vaccination failure, it is a good idea to use 5 to 10% more doses than the total number of animals. The temperature of the water to be used for the vaccination should be cool by preference. It should never exceed 27 ºC. If possible, reconstitute the vaccine with a specific diluent or physiological saline. It is important to rinse the vials thoroughly to get the most out of them. If not, we are exposed to a 15% loss. Once the vaccine is reconstituted, it should be used within 1.5 hours after reconstitution.

For adult birds, there should be two to three operators per farm. In closed/dark houses with a controlled atmosphere, minimize ventilation, reduce the light intensity to keep the birds calm and switch off the heating in order to guarantee the appropriate droplet size and correct distribution of the vaccine. In open houses and during hot weather, vaccinate very early in the morning and close ventilation openings as much as possible. Each operator should walk slowly, making two complete passes through the house, directing the spray nozzle 0.3-0.5m above the heads of the birds.

There are some different situations where the application will not be effective. We should avoid vaccination if the animals are in a poor state of health or if the equipment for vaccination is not in good condition for use. Also, the preparation and the environmental conditions of the poultry house should be correct to help the vaccination and to avoid further stress on the turkeys.

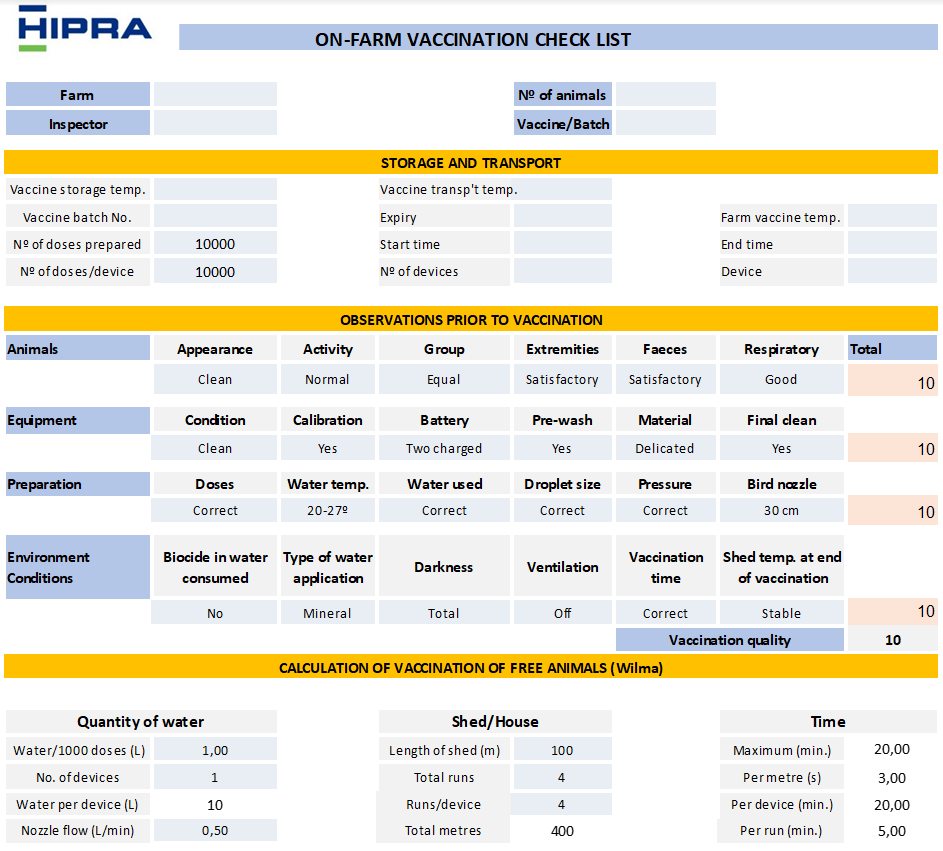

All this can be controlled if we use a good vaccination protocol.

To calculate the parameters, we first need to know how much water we need. This depends on the dose of water per 1000 doses of vaccine that we want to use. Normally, this water should be between 450 ml and 1l per 1000 doses of vaccine. Secondly, the number of devices that we need for that amount of water. The idea is that a vaccine operator should not carry a device with more than 10 litres of water.

Furthermore, it is important to know the flow at which the medical devices work, because that will show us the time that we have left before the water is used up. After that, we need to define a strategy for the total number of runs that have to be made in the poultry house in order to make the vaccination homogeneous.

When we have that information, then we can know the timings and we need to make sure that the application will not take longer than 30 minutes.

As a summary to the application part, nowadays, it is worth investing in a good device that can reach the TRT vaccination drop size to give protection to our turkeys.

Which vaccination programme should I use?

TRT is a very important disease for turkeys, so the vaccination programme should be very accurate. Depending on the duration of the production cycle, we should consider how many live vaccines to apply.

To help this decision, we recommend using the 6 weeks rule. Since the duration of immunity for live vaccines against TRT is from 6 to 9 weeks, we take 6 weeks, so we do not take any unnecessary risks. After that, we should plan the vaccination programme, separating each live vaccine by no more than 6 weeks and making sure that protection will be complete during the production cycle. This is why it will be different among the fattening strains, and different from the breeders. For breeders, we can apply the same rule, only that we also need to add 2 killed vaccines. To sum up, it is better to keep a maximum distance of 6 weeks between live vaccines and a maximum distance of 6 weeks between the last live vaccine and the end of the production cycle.

Category |

Duration of the production cycle |

Live TRT vaccine |

Killed TRT vaccine |

Meat type Females |

12-15 weeks |

D 0 + week 2 + week 6 |

|

Meat type Males |

15-20 weeks |

Day 0 + week 2 + week 6 + week 10 |

|

Breeders |

28 weeks |

Day 0 + week 3 + week 9 + week 12 |

Week 17 + week 25 |

Vaccines, what should we expect?

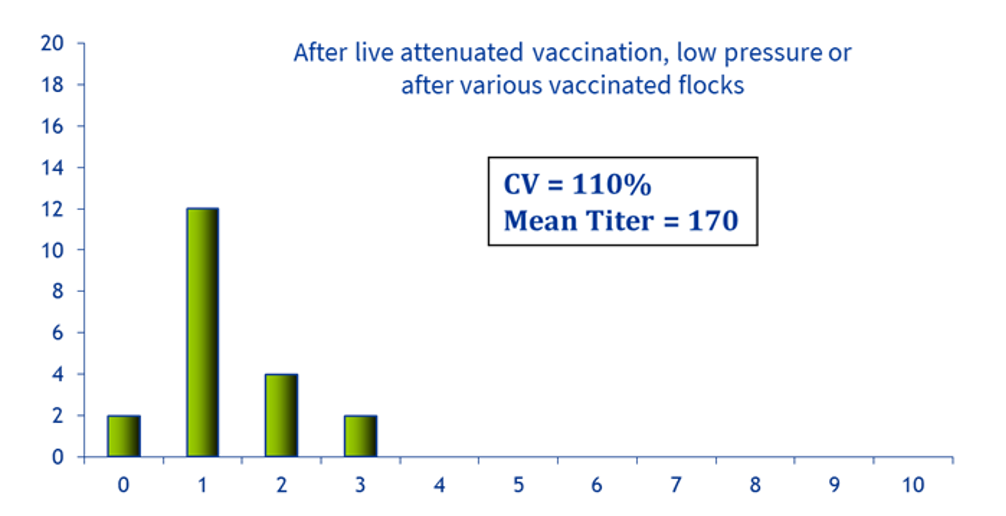

Firstly, we need to take into account that the level of serological response induced by live aMPV vaccines is not a good indicator of the degree of protection, in accordance with Ganapathy et al. (2007).

However, it may be useful for noticing the differences between flocks in which high pressure of field virus persists (with high levels of seroconversion) and flocks in which the vaccine is displacing the field virus.

Normal results after live vaccination in a low challenge situation.

Speaking about the vaccine to be used, there is no great difference between the subtypes. Both subtypes have shown good cross protection but it’s true that subtype B is more prevalent around the world because of its greater invasiveness. That's why its persistence in tissues is longer.

Another point is to choose a vaccine that is registered for turkeys, otherwise our animals will not be completely safe. Finally, these vaccines can be of either turkey origin or chicken origin, but for turkeys this is a severe disease and normally the ones of turkey origin produce a greater reaction.

Conclusions

To conclude, in order to combat TRT in turkeys we need to give local immunity and for that, we need to work with the correct droplet size. This will lead to a correct vaccination and therefore we will have uniform immunity.

We also need to start working with data and make accurate and precise calculations to achieve success, such as correct vaccination parameters and flock monitoring to develop effective vaccination plans.

| References | ||||

|---|---|---|---|---|

| Buys, S. B., DU Preez J. H., (1980). A preliminary report on the isolation of a virus causing sinusitis in turkeys in South Africa and attempts to attenuate the virus. Turkeys. 28, 36. | ||||

| Gough RE; Jones RC, 2008. Avian Metapneumovirus. In: Diseases of Poultry, 12th edition [ed. by Saif, Y. M. \Fadly, A. M. \Glisson, J. R. \McDougald, L. R. \Nolan, L. K. \Swayne, D. E.]. Ames, Iowa, USA: Blackwell Publishing, 100-110. | ||||

| Jirjis FF; Noll SL; Halvorson DA; Nagaraja KV; Townsend EL; Sheikh AM; Shaw DP, 2000. Avian pneumovirus infection in Minnesota turkeys: experimental reproduction of the disease. Avian Diseases, 44(1):222-226; 5 ref. | ||||

| Chacón JL; Mizuma M; Vejarano MP; Toquín D; Eterradossi N; Patnayak DP; Goyal SM; Ferreira AJP, 2011. Avian metapneumovirus subtypes circulating in Brazilian vaccinated and nonvaccinated chicken and turkey farms. Avian Diseases, 55(1):82-89. http://www.aaapjournals.info/doi/abs/10.1637/9501-081310-Reg.1 | ||||