Easing the pains of egg and chick processing

Owing to the delicacy of the products, egg and poultry processing can be a time-consuming, labour-intensive business. But a suite of advanced new machines and techniques are making tasks such as packing, grading and sorting ever more efficient.Modern egg and chick processing has come a long way over the past decade, aided by new ideas, new technology and new-age farmers. Long gone are the days of gathering hundreds of eggs by hand, and then having to wash and sort them out by size or shape before packing in trays ready for delivery or collection.

There are around 397.35 million laying hens in the European Union producing in the region of 7.7 million tonnes of eggs each year. That’s a lot of eggs to process by hand, but thankfully technology has taken over in the majority of the 28 EU members states to assist with the handling of eggs. While some countries have taken steps to invest in the latest equipment, both on farm and in factory, some of the poorer states in the EU still use traditional labour-intensive methods.

Four areas of production that have particularly benefited from new technology in recent years are in packing, grading and separating eggs - all of which have both seen advances in equipment to make processing efficient - and in sexing chicks with the use of innovative laser techniques.

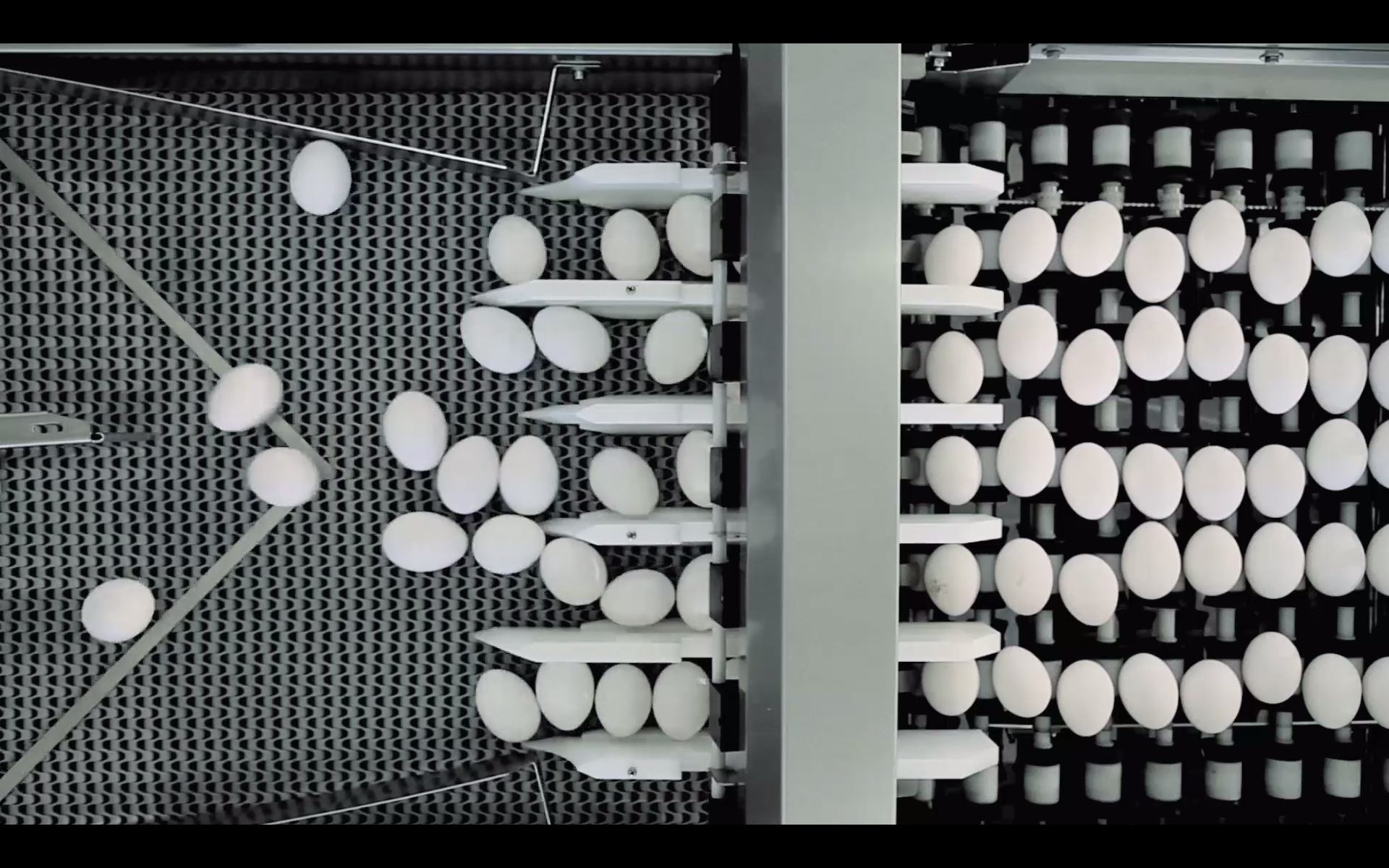

Big Dutchman’s BigPacker system

© Big Dutchman

Packing eggs on a farm is a notoriously time-consuming process - or at least it was. Tackling the issue, the German based pig- and poultry-equipment specialist Big Dutchman recently launched its new BigPacker product line. Three different farm packer models are available in this range which can pack 15,000 to 25,000 eggs per hour, making them the ideal tool for small- to medium-sized poultry units.

The new BigPacker products are distributed in cooperation with the Dutch company Moba , which claims to be the world’s leading manufacturer of egg grading, packing and processing equipment.

Big Dutchman says with adding the farm packer range to its portfolio it has completed its range of products to aid professional egg collection. Available in three sizes, the BigPacker machines speed up the packing process and handle eggs with ease. They are also available with a tray stacker as an extra option. The main advantage of this system, says the company, is its efficiency: the process isn’t held up by waiting for a sixth egg to complete a row in each tray, and it only takes one person to operate the packing machine.

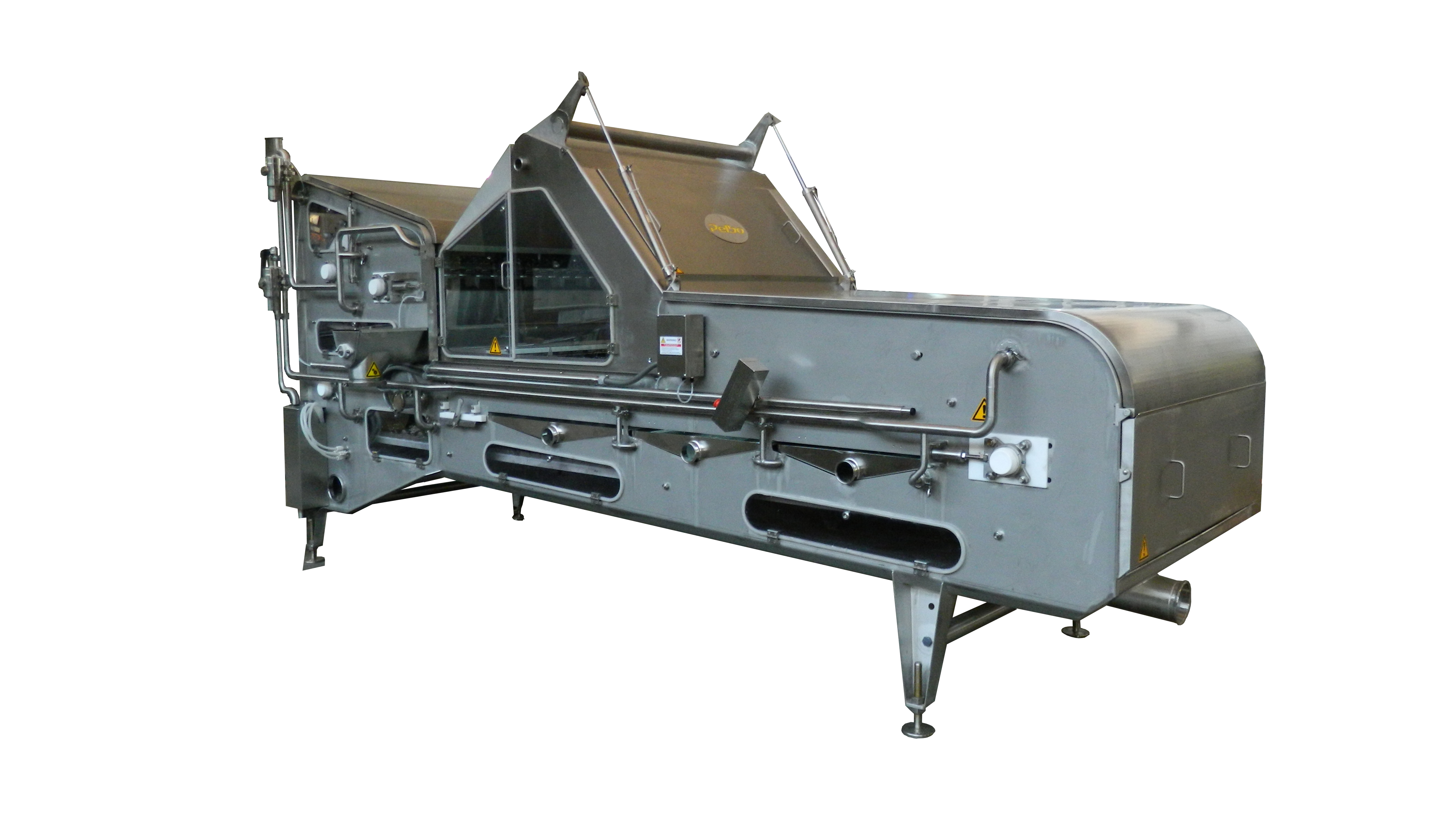

Sanovo grader

With over 60 years experience in the egg grading industry, Sanovo has launched its new GraderPro range, calling it “the next generation of egg graders”.

The largest-capacity machines can grade up to 800 cases per hour, and a key innovation is the GraderPro’s new system that ensures eggs are handled as gently as possible, to avoid breakages. According to the company’s website: “Most damaged eggs are cracked due to side impact on the eggs. Side impact appears when you transfer eggs through a machine in one direction, and while the egg is in movement, change the direction. To avoid this side impact we developed a system that only transfers the eggs in one direction at a time. We deliver eggs only one way - downwards. The downward delivery eliminates side impact and ensures exceptional gentle egg handling.”

Sanovo has also reduced the track speed by up to 25 per cent when compared to other manufacturers, following a rethink of the movements within the frame of the grader. Reducing this track speed, says Sanovo, should make for even gentler egg handling and a higher output of packed eggs in the process.

Some of the other advantages of the GraderPro include its simple design, which, says Sanovo, should require low maintenance, and a design feature that means each egg is fully traceable throughout the grading process.

The company has made a hygiene a strong focus of its design, making sure that all parts of the machine can be cleaned leaving no blind spots. There is therefore no need for disassembling the machine for cleaning.

Moba egg breakers

These days, no one should have to sit for hours breaking and separating eggs, which is why Moba has developed the Pelbo Synchro egg breaker and separators. These are high-capacity machines with extremely high yields and, says Moba, proven reliability. Synchro breakers are available in five models with capacities ranging from 20,000 eggs per hour to 226,000 eggs per hour.

The highest-capacity unit, the Synchro626, is the world’s highest-capacity breaker with the slowest and safest egg-handling speed found in the market, according to the company.

Moba egg breakers offer minimum whole-egg quantities, high-quality egg white (with less fat content) and an increase in yolk dry matter.

Laser chick sexing

Culling male chicks at one day old is quite a controversial topic, so researchers are looking into new methods of determining a chick’s sex before it is born. Using laser technology, scientists in Dresden, Germany, have been able to tell the sex of embryos at day 3.5 of incubation with a success rate of 93 percent.

During the research scientists investigated optical spectroscopy to determine, non-destructively and in-ovo, the sex of early chicken embryos. The embryo’s blood-circulation system was accessed by producing a window in the egg shell and the flowing blood was illuminated with a near-infrared laser. The blood’s fluorescence was then analysed, and differences in its intensity when examining 380 eggs at day 3.5 of incubation meant that researchers could correctly identify the unhatched chick’s sex in 93 percent of cases.

The increase of fluorescence intensity between 3.5 and 11.5 days of incubation was found to be in agreement with the erythropoietic stages, thus enabling identification of haemoglobin as a fluorescence source.

Sex-related differences in the fluorescence spectrum were found at day 3.5, and principal component analysis showed that the blood of males was characterised by a specific fluorescence band located at ∼910 nm.

As a result, supervised classification of the PC scores enabled the determination of the sex of 380 eggs at day 3.5 of incubation with a correct rate up to 93 per cent by combining the information derived from both fluorescence and Raman scattering.

Summary

Processing eggs both on-farm and in factories has been made more efficient with modern day technology reducing the labour-intensive and time-consuming aspects of the jobs, as well as improving welfare in the case of fertile eggs and male chicks. However, it is not every farm or factory around the world that can afford this equipment. The onus is on manufacturers to develop equipment that can streamline an egg producers/processors business but at an affordable price in less developed countries. While the topic of culling male chicks remains controversial, there will always be a need for a system that can avoid this. Developers of this type of technology will be under pressure to act fast to make their research become commercially viable as soon as possible.