European Showcase for Poultry Housing Innovations

Innovators in poultry housing and equipment took advantage of the VIV Europe 2014 trade show to display their latest designs. Jackie Linden reports on those that were recognised by the organisers in the Innovations Gallery at the event.With a high degree of regulation in all areas of production - particularly aimed at optimising animal welfare and minimising the environmental impacts – Europe offers the right conditions to encourage its many innovators to develop new solutions for today’s challenges in poultry production in the region. In May, VIV Europe offered them the opportunity to showcase their latest ideas to farmers from around the world at the trade show in the Dutch city of Utrecht.

Event organisers, VNU Exhibitions, set aside a special area – the Innovations Gallery – in one of the halls, where 40 of the best new ideas were gathered together and prizes were awarded to one chosen one in each of several categories.

New Ideas on Hatchery Management

In the area of hatchery developments, HatchTech won an Innovation Award for its HatchCare system. Chicks are hatched under optimum, uniform temperature conditions, delivering higher hatchability rates and stronger, healthier chicks. The system is a significant step forward in terms of animal welfare, the company says, as the chicks have access to the basic necessities of life – feed, water and fresh air – as soon as they hatch. The system allows greater flexibility over the length of the hatch window as the newly hatched chicks have chance to eat and drink before their transfer.

SmartCount™ from Pas Reform was described as a visionary new system for counting chicks. Growing demand for high-quality day-old chicks is driving the expansion of the world’s hatcheries and this requires faster throughput and accurate traceability without compromising animal welfare. Three years in development, the Smart Count can count, spray-vaccinate and assess up to 60,000 chicks per hour and deliver the chicks with an accuracy of two chicks per thousand to the boxes at the end of the conveyor. Integrating the data generated into the SmartCenter™ hatchery information system offers a high level of data analysis and batch reporting, the company says.

Progress in Ventilation

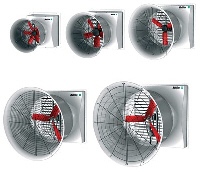

Vostermans Ventilation was promoting its Multifan Fibreglass Cone Fans, whose aerodynamic design offers optimal air performance, fan efficiency and air flow ratio. The company explained that the benefits include maximum air performance, high efficiency, low noise, high durability and ease of cleaning. The fans are available in direct drive (18, 24 and 36 inches) and belt drive (50 and 54 inches).

With its Fantura air inlet system, Fancom promises an end to cold air dropping into the poultry house. Instead, the incoming air is bundled for better throw, providing a good flow of fresh air throughout the house - even on minimum ventilation - which means dry litter, fewer foot problems and the birds remain healthy and grow better. Furthermore, the air entry cones offer 10 per cent more capacity, says Fancom, which reduces both air resistance and energy consumption.

In response to the challenge of maintaining a constant environment inside the poultry house despite changing external conditions, Stienen BE displayed its AeroSolution. This comprises three elements: the uniquely-shaped AeroWing air inlet, which offers constant air flow into the building; the AeroComp system that compensates wind strength and direction to control the pressure within the house; and the AeroX heat exchanger to maintain a constant set temperature for the birds.

Controlling the emission of ammonia and odour from a poultry house with a minimum of energy was the aim of the four new elements of the exhaust air-cleaning system from Jansen Poultry Equipment. Dust, feathers and other contamination are removed from the exhaust air from the house by means of the energy-efficient EcoFriend® biological air-scrubber, AmoControl® chemical air-scrubber, Manure Dry Systems Classic and Compact and the AluBreeze® heat exchanger.

Advanced Climate Control

Based on the proven technology of its Orion computer, Hotraco Agri BV has further developed the systems and added new software for its new Fortica computer, offering higher reliability and a range of new smart functions and corrective checks.

The company won the VIV Europe Innovation Award for ‘Housing and Farming’ with the Fortica, which was designed to be highly intuitive, the touchscreen is based on the interface with a smartphone or tablet and can be customised by the user in any language. The system can be accessed via the internet, anywhere and at any time, allowing complete control over the poultry house climate, feed and water, egg flow and bird weighing.

At VIV Europe, Skov A/S launched a new management system for breeders, including a new climate and production computer and a FarmOnline management module. In a series of presentations at the show, Tommy H. Krogh (climate and production specialist) and Kim Jensen Moeller (product manager) discussed the avian growth curve, Key Performance Indicators, production and monitoring control and tools to improve breeder production.

Developments in Feeding Systems

A new feed conveying system was featured in the Innovations Gallery by Big Dutchman. The FlexVey PUR comprises a flexible tube of wear-resistant polyurethane (PUR). It offers a number of advantages: the conveyor lasts four to five times longer than other similar systems. It is also quieter in operation and because of its flexibility, it can move feed efficiently around curves and bends. Currently, 75- and 90-mm diameters are available.

The Valenta broiler feed pan was introduced at VIV Europe by VDL Agrotech as a versatile option to meet the demands of the modern industry, offering the young chick easy access to feed and optimising feed efficiency over the growing period with labour-saving features.

The low edge of the pan allows even day-old chicks to access to feed and there is no grille to trap them. The pan can easily be adjusted to one of the six feed level settings, allowing mash or pelleted feed to be available to the birds constantly without spills and waste. Labour saving is achieved by easy opening of the pan, if required, but it can also be cleaned while closed with the water draining through holes in the base.

New-Look Lighting

AgriLamp presented its ALIS tube, a patented lighting solution designed for use inside poultry cages, together with the ALIS Induction Power System – contactless power technology that allows the LED fixtures to be clipped onto the cable in order to turn on. According to the company, it is simple, safe and energy-efficient and because it is dimmable, it allows the birds to be illuminated to the optimum level at all phases of production.

Broiler Housing in the 21st Century

VDL Agrotech is a member of a partnership with Plukon Food Group, Sommen Ventilationsystems, Vista landscape planners, Wageningen UR Research and Nijkamp poultry farming developing a new concept in broiler house design.

The Windstreek concept makes use of natural ventilation and light, reducing energy use and offering the birds plenty of space. Brooding hoods offer warmth and protection to the chicks in their first few days. The innovative building design is open and attractive to the public and offers comfortable working conditions for the farmer. The first Windstreek house is due to start construction later this year.

On-farm Hatching in a Traditional Broiler House

Vencomatic Group has recognised the need by broilers for optimum conditions from their first day to grow to their potential and remain healthy, and that under normal commercial conditions, newly hatched chicks may have to wait one or two days without feed and water between hatching and delivery on the farm.

In 2006, the company launched the Patio, a system for on-farm hatching of eggs in multi-tier compartments that has become popular in several countries – with 25 million bird places worldwide - and is delivering good results.

The system is accepted to EU welfare standards and, at the moment, there are several projects in the Netherlands and Hungary with a total of almost half a million bird places.

With these constraints in mind, Vencomatic Group has combined the hatching and brooding phases on-farm in its new X-Treck system. The farmer receives eggs on day 18 of incubation on setter trays, which are suspended over the floor in a standard house. The hatched chicks gently fall off the trays onto the litter and have immediate access to feed (in pans or on chick paper) and water from drinkers. Once hatching is complete, the setter trays are removed and the framework of rails is winched up out of the way of the birds and workers for the rest of the growing period.

Early results with the X-Treck have been excellent, the company says. Among the advantages they give are that the chicks are saved the stress of transportation, disease risks are reduced and the birds get off to a good start.

Kees Koolen is a farmer in Bergeijk in The Netherlands who is always open to new ideas. He installed the X-Treck in one of his six broiler houses and is now rearing his fourth flock of Ross 308 birds with the system.

He explained that his main motivation was to try to prevent leg problems in the birds thought to be caused by an Enterococcus infection - without resorting to antibiotics.

Key to success, he has found, is to ensure that the temperature in the house meets the needs of the hatching eggs and newly hatched chicks.

With the eggs coming into the house earlier than with a standard delivery of day-old chicks, this could be a challenge but Mr Koolen finds he can heat the air in the house to the required 36 degrees Centigrade before the arrival of the eggs. The trays are easily rolled into place on rails, which are initially suspended about one metre above the house floor.

When the chicks first hatch out, the trays are lowered. By that time, the floors and walls have warmed up, litter is applied to the now warm and dry floor and the feeders and drinkers have been set up.

So far, Mr Koolen said, hatchability with X-Treck has been better than expected, which he puts down to the good start made by the later-hatching chicks that would otherwise have perished. Overall mortality has been slightly lower and there has been no Enterococcus or other diseases that require antibiotic treatment.

Now that he has established the process to get the floor temperature right, the flock achieved a seven-point improvement in feed efficiency compared to those reared in the conventional way in the next house.

Among the main advantages of the X-Treck, according to Mr Koolen, is that his chicks are settled into eating and drinking one day before they would have been if delivered as day-olds.

He is very enthusiastic about the system, telling ThePoultrySite: “The pre-heated air mixes with the house air in the ridge of the house. As a consequence, there’s no fall down of cold air and the chicks do not experience any draughts. The result is dry litter. The atmosphere created has a positive influence on bird performance."

July 2014