Feed Sanitation: Heat treatment as a method for the decontamination of poultry feeds

An overview of the process, equipment and objectives.Introduction

The traditional methods of reducing microbial contamination in feed raw materials have been compromised within the EU recently with the ban on the incorporation of formaldehyde as a feed additive (PT4). Within the EU this is being linked to an increase in Salmonella isolations. With the potential for reduced chemical use to control microbial contamination in feed to be rolled out in other countries it is important that suitable alternative methods to control contamination are put in place.

One response by the industry to the ban on formaldehyde has been the introduction of new organic acid blends and novel compounds for feed sanitation. Organic acids are effective in reducing Salmonella challenges. However, they do not provide a clean, biosecure break in the mill and their performance is very reliant on formulation, the mixing performance in the mill and the time allowed for their action.

With higher generation stock as legislation tightens and public awareness heightens, the use of heat treatment for the decontamination of poultry feeds has become more popular and heat treatment is now generally seen as an effective means of Salmonella destruction in raw materials.

The purpose of this document is to review the heat treatment of poultry feeds in terms of the specifications required to ensure decontamination and the types of equipment that can be successfully employed.

Heat treatment - objectives

There are many recommendations for the heat treatment of poultry feeds published in the literature. For broiler feeds, it has been reported that a moderate level of heat treatment such as 80°C (176°F) for a two minute retention time is sufficient to kill Salmonella. In reality, it is likely to kill most of the Salmonella and damage any remaining Salmonella. By the time these damaged Salmonella start to repair and grow to reach an infective dose detectable by sampling, the broiler flock could be depleted, and the flock considered negative. With breeder flocks however, the Salmonella has a much longer time to grow to a detectable, infective dose level and Salmonella outbreaks can occur later in the life of flock. For these flocks, heat treatment temperatures for feed need to be higher for longer periods of time to ensure maximum Salmonella destruction.

So what are the specifications for successful heat treatment? Firstly, the incidence of Salmonella and the levels of contamination need to be considered. This will vary depending on the raw material(s). Literature review would generally tell us that the highest levels of Salmonella in crop-based raw materials (soya, rape meal and sunflower) would be in the region of 105 per gram. To eliminate Salmonella, heat treatment needs to be sufficient to reduce this level to zero.

Secondly, there must be a balance between the need to destroy pathogenic organisms such as Salmonella and the effect of heat on, for example, vitamin inclusion in the finished feed, the levels of starch gelatinisation achieved, protein denaturation and other anti-nutritional factors.

Once the feed has been decontaminated it is equally important to ensure that measures are in place to prevent the re-contamination of feed after treatment. A feed mill using heat treatment to produce biosecure decontaminated feed must have distinct “dirty” (i.e., before heat treatment) and “clean” (i.e., after heat treatment) areas. Heat treatment is seen as a breakpoint in the feed mill production process where decontamination of the feed takes place at a boundary between the “dirty” and “clean areas”. The clean area must be constructed in a way that will protect the feed from being re-contaminated by the dirty area. Biosecure boundaries and procedures must be in place. This commonly includes separate staff for each area and filtered air, usually to HEPA standard, to the clean area to prevent re-contamination after processing. A full hazard analysis critical control point plan (HACCP) is also required to set standards, provide a monitoring and risk analysis to the clean feed, and to monitor any deterioration in the mill structure or process conditions.

Heat treatment

Ongoing work within Aviagen has established that heating at 86°C (187°F) for 6 minutes at 15 percent relative humidity is enough to destroy mesophilic bacterial populations at a level of 105 per gram. Knowing this it is possible to theoretically establish thermal processes (heat treatment) for different types of equipment. Different equipment will require different thermal processes to achieve the same level of reduction; because of this it is important that new heat treatment equipment is validated for efficacy to destroy Salmonella.

Heat treatment effectiveness will also be affected by the moisture content of the raw materials, the quality of the steam (moisture content) being used during the process and how the feed passes through the equipment. The feed should pass through the heat treatment equipment on a first-in, first-out basis to ensure even heat treatment.

It should be noted that the heat applied to feed as part of the process of producing pelleted feed will not be enough to kill Salmonella and should not be considered as part of the heat treatment process.

Heat treatment technology

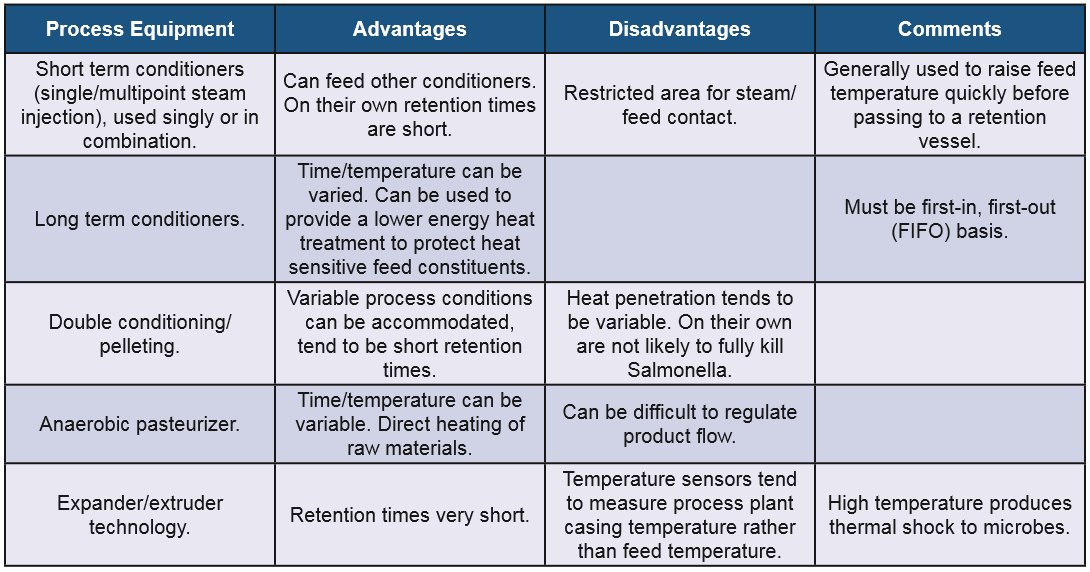

There are a range of different technologies available to achieve the desired standards of heat treatment described earlier (86°C/187°F for 6 minutes at 15 percent relative humidity); these are listed in Table 1.

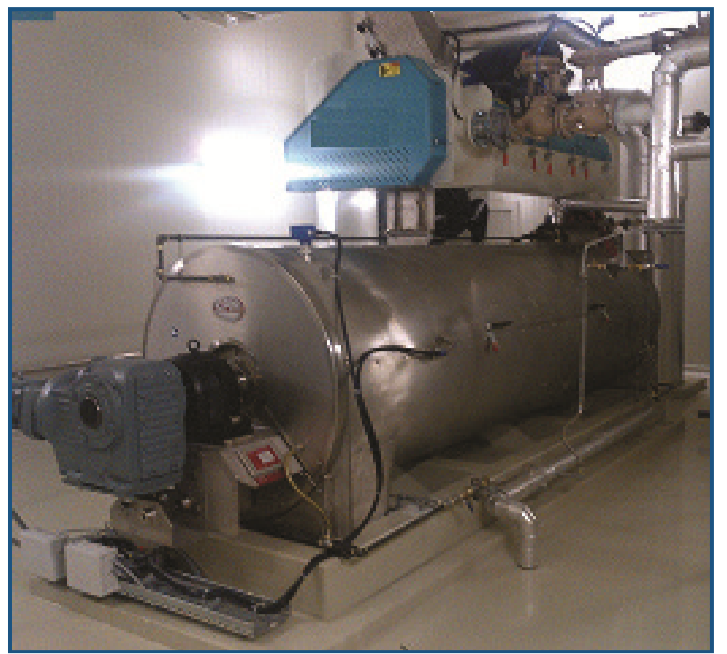

Aviagen currently uses steam conditioning followed by long term retention at 86°C (187°F) for 6 minutes at approximately 15 percent moisture content (including steam addition). The conditioner introduces steam to the raw materials and the retention vessel ensures an even heat treatment through its first-in, first-out properties (Figure 1).

Upper conditioner adds relatively low pressure steam and mixes with the raw materials. Lower retention vessel retains the set temperature and time. No steam added.

The choice of equipment and heat treatment parameters used will depend on the overall objective, e.g., “Free of Salmonella” (i.e., a reduction in counts to a level below that of the infective dose for day-old chicks), “Guaranteed free of Salmonella” (complete kill i.e., a 5 log reduction [from 105 per gram to zero] with 99 percent confidence), and the type of product to be produced: mash, crumb, expandate, pellets, etc.

Conclusions

In light of the recent EU ban on formaldehyde as a feed additive, appropriate alternatives for feed decontamination must be in place.

Heat treatment of poultry feeds has been shown to be an effective decontamination method for Salmonella and provides a ‘breakpoint’ in the feed production process to aid biosecurity. However, each heat treatment system requires validation to establish efficacy and to determine the levels of ongoing risk. Effects on vitamin degradation require quantification, and high levels of downstream biosecurity are required.