Full Speed Ahead to Debone Automatically

With modern poultry slaughter lines running at more than 8,000 birds an hour and recent controversial USDA recommendations to increase those speeds to around 10,000 an hour, the requirement for greater automation on the processing line to keep up the pace is growing.More and more poultry processors are installing high-speed lines that tackle the evisceration process and debone the carcass.

Traditionally, birds have been cut up and deboned on cones and semi-automated cone lines increased the speed of the operation.

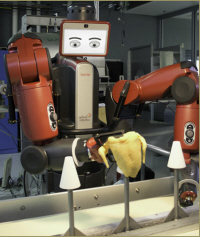

Research at Georgia Tech is now investigating using robots to put the birds onto the cones automatically.

The Agricultural Technology Research Program (ATRP) has acquired a manufacturing robot for use as a research test bed.

The US-made Baxter robot from Rethink Robotics can handle many repetitive production tasks that are typically difficult or expensive to automate, freeing human operators to focus on more value-added jobs.

The robot will go into action this year (2014) to evaluate Baxter’s ability to automatically place chicken carcasses on cones for processing in a poultry plant.

“The acquisition of the Baxter robot is very exciting for ATRP as it provides us with a tool that is designed specifically to operate in close proximity to people in a manufacturing or other labour-intensive setting. This is an extremely important technological development as it will enable the use of robotics in places that previously would not have been possible. We are very interested in leveraging this tool and capability to support many of the manual tasks in a poultry processing environment,” said Dr Doug Britton, ATRP programme manager

However, while deboning birds on a moving cone offers good yields and effective production, the lines rely heavily on the skill of the butcher carrying out the operation and to achieve efficient production they are highly labour-intensive.

Highly skilled butchers can fully debone about 150 chickens an hour but to have efficient production at the end of high speed slaughter lines, the speeds need to be 10 times as fast.

The increased speeds and the demand for greater efficiency in production are also dictated by the fall in skills on the production line, the high cost of labour and a consumer demand for greater convenience in the products on the supermarket shelves.

Consumers now want deboned, skinless products that are ready-prepared and ready-to-cook.

According to the Dutch poultry processing equipment company, Meyn, which is one of the pioneers of automated deboning lines: “The demand for deboned poultry products throughout the world has created an intensive and vast growing market.

“The eating habits of consumers have changed considerably over time, and a clear shift can be seen from whole chickens towards cut up and deboned products.

“Deboned meat is also widely used as raw material for the increasingly popular convenience food products.

“Deboned poultry meat, therefore, finds its way to an endless variety of end products, destined for markets all over the world.”

The aim of companies such as Meyn is to provide processors with highly efficient deboning systems that support the poultry processing industry in realising the right quality product and to satisfy the growing demand for deboned poultry meat.

|

| Meyn chicken deboning technology |

The demand on the automated lines is for precisely produced products in similar or equal portion size, cleanly and hygienically manufactured at speed.

“Good deboning is all about high yields, high quality and safe end products,” according to equipment manufacturer Marel Stork.

The equipment also has to be versatile in the products it produces and be technologically robust to meet the demands of high-speed production.

As these demands grow and technology advances, so too are production and deboning lines.

Research Advancing

The latest advances are in the field of 3D technology and product recognition to enable the deboning tools to more accurately handle the awkward and varied shapes of the chicken carcass and parts of the carcass in tasks such as gripping, turning and cutting.

While the skilled butcher would have no difficulty manipulating the portions, fixed automation and current robotics techniques result in loss of accuracy, precision and yield.

Researchers with the Georgia Tech Research Institute’s ATRP reported last year that they were working on an exploratory project with the goal of developing perception algorithms that will allow continual “perception during manipulation”.

In addition, the algorithms will be designed to work with any type of object, having the ability to learn new objects and thus adapt to many different applications.

The research institute said that this is particularly beneficial to the poultry industry because of the difficult nature of sensing and handling meat products.

Combined with robotics and manipulation research, the development will enable advanced robotics platforms for the next generation of poultry processing.

Georgia Tech’s envisioned full system will be capable of learning a new object model and then use it for the detection and tracking of the product throughout manipulation. Basically, the system will perform general object modelling (learning) with skeletal and shape components to identify key features specifically for deformable objects, allowing the tracking of those objects in real-time.

The development has been taking place in four steps.

Sensing: For this application, it is expected that both 3D and 2D colour data are required. The application will determine the requirements and sensors used in an end product; however, a generic research sensor is important here. For this project, the researchers chose the Microsoft Kinect, a general gaming sensor being used for robotics research. It includes a standard colour camera, an infrared pattern projector and infrared camera, to sense both depth and location of every pixel.

Segmentation: Segmentation means determining which pixels in the field of view belong to the object and which belong to the background. During learning, a non-model based system will be used to detect the object surface, and this data will be sent to the tracker for modelling. During run-time, the model will be used to detect the object surface, and the tracker aligns the model for complete detection.

Tracker: The tracker takes data from segmentation to track the object over several frames, updating the model during learning, or morphing the model during run-time to align and match the current state of the object. This alignment and matching occurs in 2D to track segmented image data as the object moves, and in 3D to track and solve for a full 3D solution of the object’s state. This process is standard for rigid objects; however, meat is not rigid, and has few image features to track, so this makes alignment difficult. In fact, learning a deformable object model and matching to a constantly deforming object is significantly more difficult.

Model: The model will be a basic triangle mesh that can store colour and texture, size and shape, and variable parameters for object motion. This type of model is crucial because it must be capable of handling various constraints, and be feasible for detection and tracking in real-time. Traditional 3D animation and modelling - such as the type used in video games and movie special effects - will be considered to develop skeletal and skin models for poultry objects. As the object is deformed during learning, the mesh will grow and adapt, and during run-time, the mesh will stretch and move to match the object within its learned constraints.

|

| Sample images of a chicken model during manipulation. The top row shows a 3D image of the chicken with its corresponding simulated model on the bottom row. |

Bone Contamination

No matter how efficient the automation, however, there is still always the risk of contamination of the end product through bone fragments.

The need for a reliable inspection system has risen greatly in the past five years as the demand for deboned meat has risen sharply.

The standard inspection process for bones in meat is for workers to feel for bones manually. It is clear that this time-consuming manual inspection method is insufficient to meet the increasing demand for deboned meat products.

The alternative to manual inspection is automatic X-ray imaging inspection, a technology currently being installed in several plants in the United States and Europe.

Most automated lines now also include scanning equipment on the line to detect fragments of bone and other foreign objects in the meat portions before they are sent for packing or further processing.

The most traditional bone-scanning equipment uses X-ray technology such as the BoneScan from Meyn, MeatMaster from Foss and the SensorX system from Marel.

These systems automatically detect bone fragments and other foreign bodies in the meat as the product passes along the conveyor.

Meat products that are suspected to contain bone can be automatically removed from the product flow and dropped in a bin or a conveyor for further manual inspection.

The technology for bone inspection on the line as with the deboning equipment itself is also continually advancing.

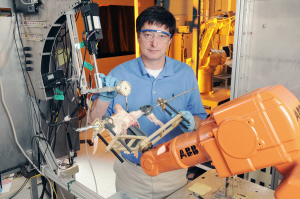

Further research at Georgia Tech in partnership with Spectral Fusion Technologies, Cagle’s, Slyvest Farms and Tyson Foods is looking at the development of an automated vision-based inspection system to detect surface bones and other contaminants of deboned meat in poultry processing plants.

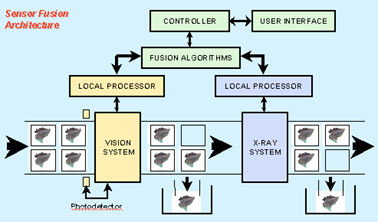

The ultimate objective of the development effort is to combine or fuse vision and X-ray technologies in order to provide the poultry industry with an accurate and thorough on-line, real-time inspection system.

The best of the commercially available systems report accuracy levels in the range of 95 to 98 per cent for bones that are at least 2-mm cubed and have sufficient density.

However, fan bones are long and slender with thickness generally less than 2mm.

The X-ray manufacturers make no guarantee on detecting fan bones but the estimates on detection are on the order of 30 per cent.

An improved method for meat inspection that finds all types of bones is needed before widespread use of the technology is made.

Georgia Tech researchers have integrated their vision inspection system into a full-scale laboratory test facility.

The vision inspection system can be a stand-alone unit or it can work in conjunction with an X-ray inspection unit.

The vision-based unit can detect surface bones (particularly fan bones), while the X-ray-based unit can detect larger bones buried in the meat.

Recent activities have focused on refining the settings of the vision-based imaging system to yield high-quality images of moving parts for processing.

Specifically, three issues were addressed: synchronisation, signal interface box and illumination refinement.

Synchronisation was achieved by adding a photo detector. An electronic interface box was designed and installed to accommodate all input/output signals as well as the power supplies for the encoder and photo detectors.

Illumination refinement was achieved by placing high-intensity, high-frequency fluorescent light bulbs into a dome illuminator to increase illumination intensity, thus maintaining a reasonable aperture and gain setting at higher shutter speed.

The research team also purchased and set up a conveyor belt to facilitate on-line imaging of chicken parts.

Extensive testing of chicken parts was conducted in order to expand the image database.

Researchers have so far tested 665 chicken breasts, and more than 1,700 images are stored in the database. The images are grouped under sub-directories according to the sample's date and the source. Under one sub-directory, images are labelled according to their defects.

Researchers have also performed colour analysis of chicken parts to determine features that distinguish bones from meat and bloodspots; in addition, researchers have searched, tested, and refined shape features for best classification result.

Finally, researchers have implemented the detection algorithm for on-line, real-time inspection.

This fan bone detection and identification algorithm consists of four operations: image acquisitioning, pre-processing, colour analysis and shape analysis.

The Georgia Tech researchers are now focussing on the development, testing and evaluation of a cost-effective, reliable, and robust fused vision/X-ray inspection system.

Fusion algorithms will be tested initially in the laboratory, and the hybrid vision/X-ray system will be optimised and tuned to detect all fan bones while minimising false alarms. The vision system also will be be tested at a processing plant in conjunction with an existing X-ray inspection system.

A 'productisation/commercialisation' and technology transfer phase will follow, aimed at bringing the results of this research and development effort to Georgia’s poultry industry.

In other recent research, a team from the USDA ARS at the Russell Research Center in Athens, Georgia, investigated the use of hyperspectral imaging as an alternative to X-rays as a means of detecting bone fragment in poultry meat products.

The research looked at a combination of transmittance and reflectance hyperspectral imaging and the experiment results showed that the detection of bone fragments in breast fillets 1-cm thick was 100 per cent.

However, the system also threw up some false positives and the research team at the time recommended that here was a need for further research to reduce the 10 per cent false positive anomaly.

January 2014