IPPE: Flagship product demos with ORKA Food Technology

Learn more about the Egg Tester Ultimate and the Wireless Egg NodeJosh Yoshida, Vice President of Sales and Marketing at ORKA Food Technology, spoke to The Poultry Site’s Sarah Mikesell at 2024 IPPE held in Atlanta, Georgia, USA.

Tell me about ORKA Food Technology.

We are the leading worldwide manufacturer of egg quality testing equipment and have been in the market for 18 years. Our products measure internal egg quality as well as external quality. We offer six devices at this time and are actively pursuing innovative solutions in this field.

Describe the features of Egg Tester Ultimate.

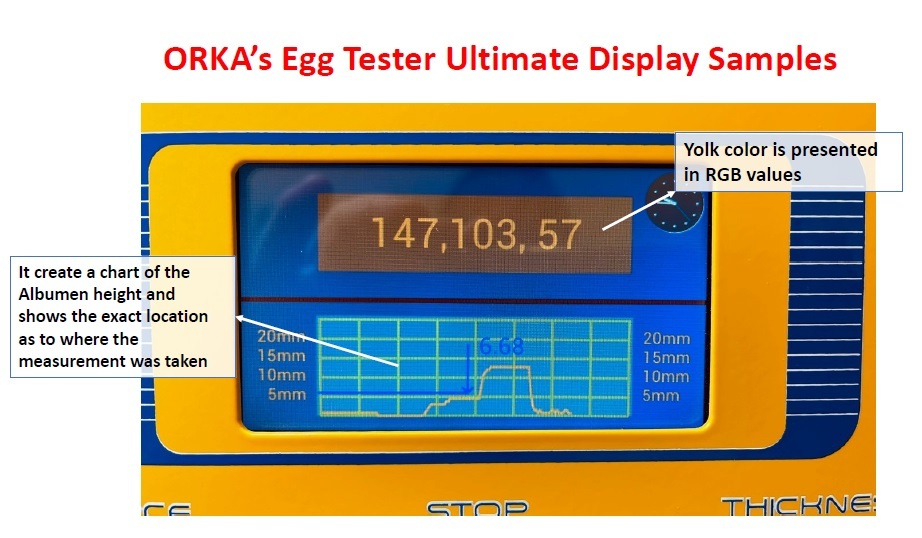

Egg Tester Ultimate is one of our flagship devices. It measures internal egg quality like albumen height, yolk color and Haugh unit as well as eggshell strength, eggshell thickness and egg weight all in one machine. It can take all those measurements in about 17 seconds.

Key features:

- Displays and prints measured values and calculated values

- Extremely high accuracy

- Constantly stable measurement, not depending upon individual operators

- Shortens the measurement time (approx.17 seconds per set)

- Proprietary Software compatible with an external PC

- Unified data, data transportability

- Self in–line calibration (automatic calibration), no need to ship unit back to manufacturer

- Comes with 2 ways of communication to PC - USB cable and Wi-Fi

- Large internal memory – up to 32GB with SDHC card

- Large 3.5’’ color/graphic display

- Internal speaker for voice instructions (optional)

- Equipped with thickness gauge storage compartment for transportation

Describe the features of Wireless Egg Node.

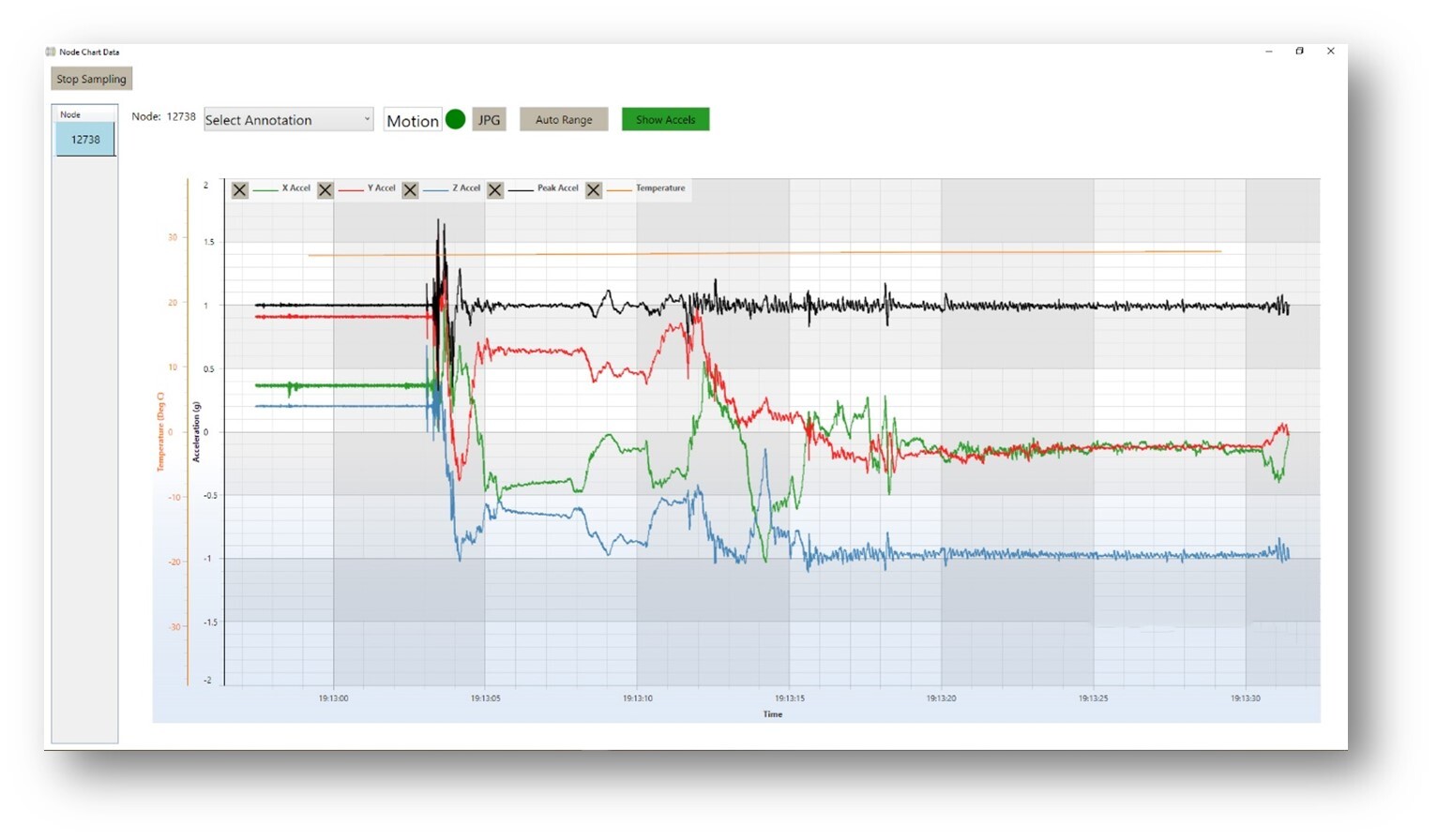

The Wireless Egg Node shows you exactly where eggs are being damaged in your system, providing a real-time measure of shock, vibration, rotation, tilting and temperature that your eggs are subjected to.

By allowing our red Wireless Egg to move through your system alongside other eggs – from the cage to the conveyor system and through grading and packing installations to point of sale – it identifies where eggs are being cracked or damaged so you can pay attention to that specific area and take corrective action. The goal is to reduce those rough spots and improve your egg movement systems.

Key features:

- Simultaneously transmit real-time data and log to memory

- User-programmable sample rates up to 512 Hz

- High speed sampling, node-to-node synchronization up to +/- 32 microseconds

- Preservation of data integrity under most operating conditions

- Remotely configure Egg Nodes, acquire and view sensor data with ORKA Node Controller® software

- Stand-alone radio communication (2.4 GHz), enabling extended communication range exceeding Bluetooth™ devices

- Simple, user-friendly ORKA Node Controller® Graphing Software that includes:

– Each of the three axes of acceleration separately

– Total impacting force

– Zoom in/zoom out for granular detail of events

– Remarks and point of interest on the real time chart

– Snapshot from the tablet’s rear camera of what is happening at that moment

Normally, about 8% to 10% of the eggs are broken on the way to consumers. We’ve seen a dramatic reduction in breakage rates of eggs, and the data is captured in real-time so you can quickly identify hazard areas for your eggs.

This tool can be especially helpful in Latin American or Asian countries where systems are sometimes not well calibrated. However, it’s a useful tool in any system to monitor breakage rates.

Who should purchase your equipment?

We have a variety of potential customers who are interested in egg quality like layer and egg producers and feed companies as well as universities, diagnostic laboratories and laboratories based at layer operations. However, I would say that layer and egg producers are the largest share of our customers.

Despite the recent challenges with avian influenza in the layer segment, we’ve seen an increase in sales the last few years which is a testament to our products but also to the industry – they are looking for ways to monitor and improve egg and eggshell quality. This is important for producers’ bottom lines and can impact consumer costs at retail stores.