Managing birds' microbial environment with positive biofilms

Ensuring a safe microbial environment during the whole production cycle is a mustMicrobes are everywhere

In farm buildings, all surfaces — floors, walls, ceilings, and equipment — are colonized by microorganisms mainly in the form of biofilms. These biofilms can be harmless, positive, or even negative for the animals if they contain pathogens.

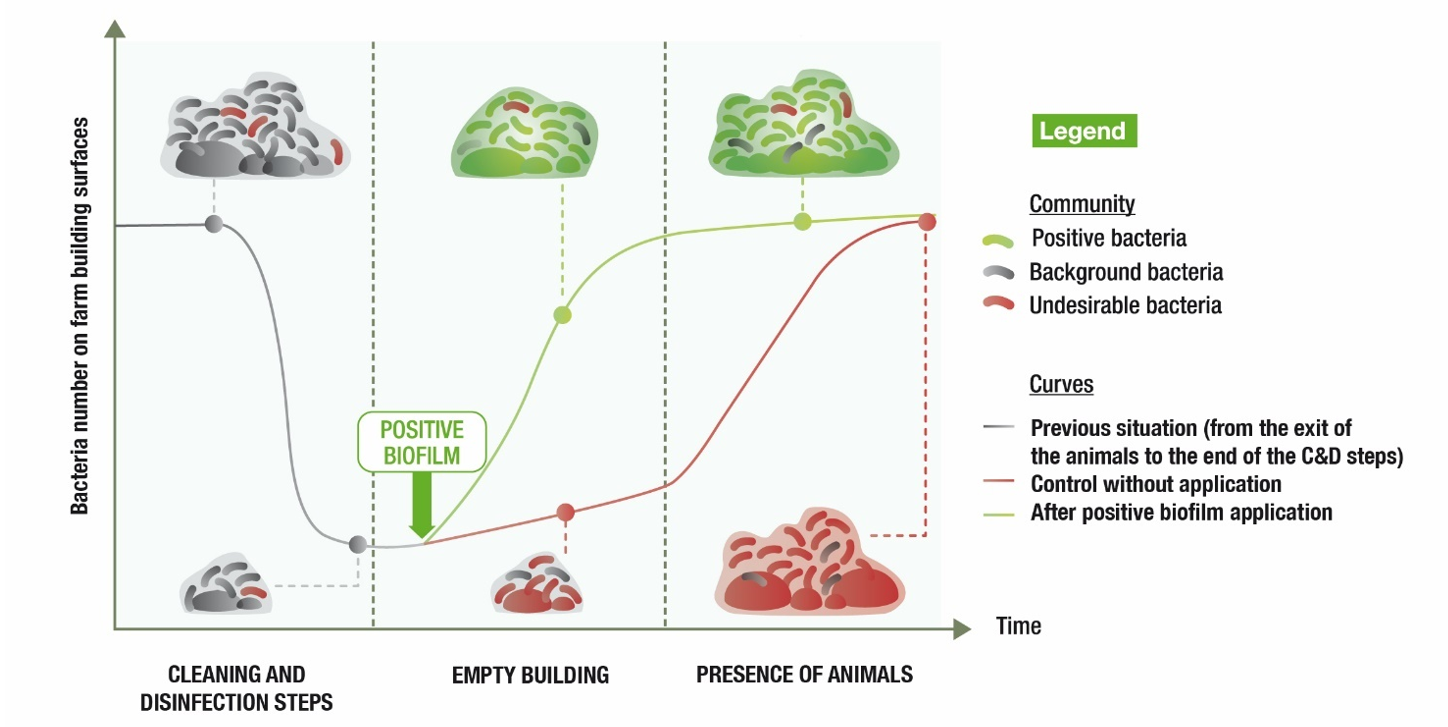

Before a new batch of animals enters the building, cleaning, and disinfection are necessary. However, the surfaces do not remain sterile. Microorganisms carried over from the animal environment (air, dust, litter, housing equipment, etc.), and from the new animals themselves, quickly start recolonizing the surfaces, forming biofilms. These microorganisms can be undesirable bacteria or potential pathogens.

What are biofilms?

Do you know that 90% of the bacteria biomass on Earth is organized as biofilm? A biofilm is defined as “a community of microorganisms attached to a surface” (adapted from Costerton et al., 1999).

They secrete a protective extracellular matrix, which can represent 85% of the biofilm biomass. Biofilms can represent very complex ecosystems developing cell-to-cell communication systems (quorum sensing). A biofilm can be formed either by beneficial (i.e. positive biofilms) or by undesirable (i.e. negative biofilms) bacteria.

A major concern is that some pathogenic bacteria in a biofilm form can be 10 to 1,000 times more resistant to antimicrobials or disinfectants compared to isolated bacteria (Briandet et al., 2012, Cabeca et al., 2012).

In animal production, any farm building or feeding equipment surface hosts biofilms that can be a potential threat to animal health if not well managed.

The positive biofilm concept

The idea is to apply beneficial bacteria along the building surfaces and equipment right after cleaning and disinfection. Those beneficial bacteria can develop into a positive bacteria biofilm inside the building, leaving less room for the development of negative biofilms (Figure 1). This is the positive biofilm concept.

Thus, a new approach to biosecurity management is possible, which includes three main steps:

- Cleaning

- Disinfection

- Application of selected bacteria that will form a positive biofilm.

Farm trials and in vitro studies have shown the potential of this new concept as part of the farm biosecurity management toolbox.

To develop a positive biofilm solution (LALFILM PRO), microbiology experts at Lallemand Animal Nutrition have selected specific bacteria strains for their ability to form a biofilm and rapidly occupy the farm surfaces.

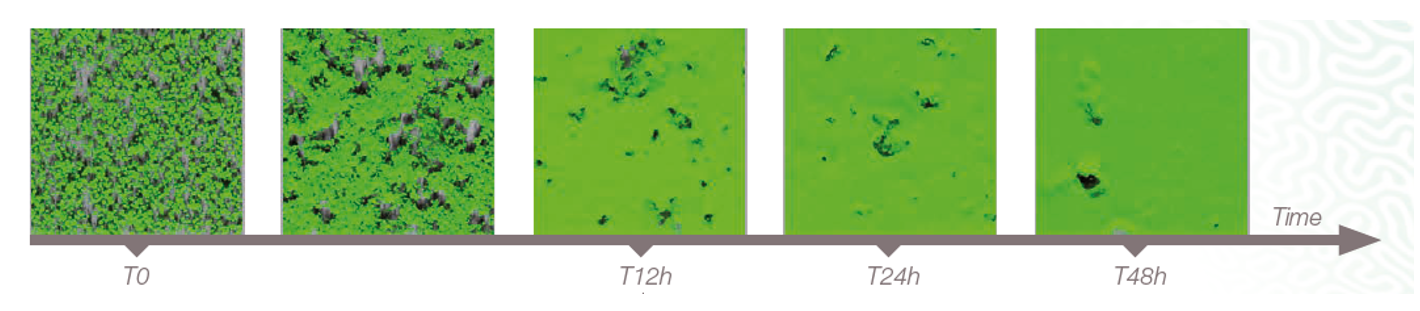

The positive biofilm formed by the selected bacteria rapidly takes up the space on farm surfaces. In vitro testing shows 90% surface coverage after 12 hours (Figure 2), leaving less room for undesired bacteria.

The selected bacteria were formulated into a specific adhesive blend that can be sprayed on both vertical and horizontal surfaces.

Application in broilers

In poultry farms, several internal biosecurity measures are applied such as cleaning, disinfection, and application of sanitary breaks. Each of these steps impacts the level of infection pressure before new birds enter the barn. The implementation of a positive microbial biofilm in the barn before animal arrival and during the barn is a real added benefit on top of these procedures.

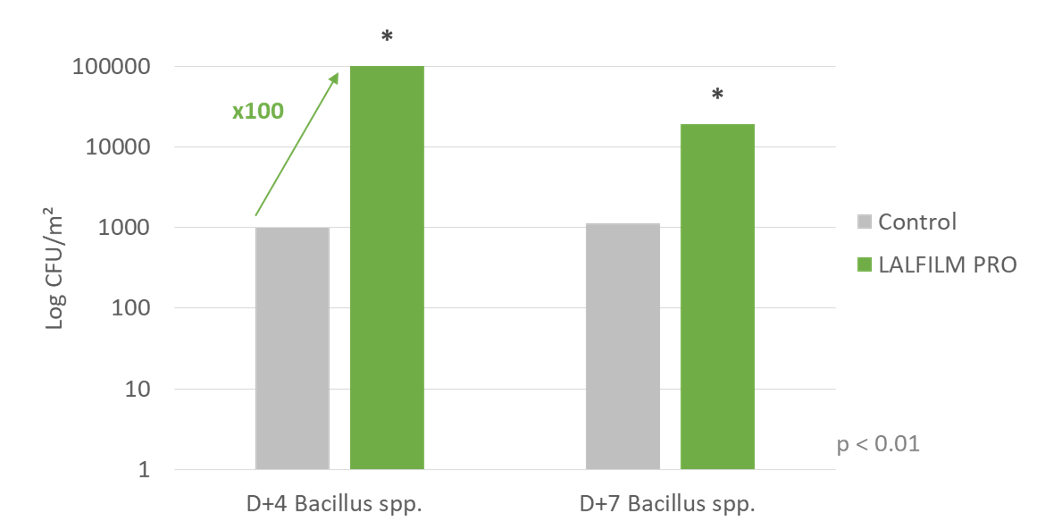

A commercial trial was conducted in a broiler barn in France. LALFILM PRO was applied at the recommended dose for poultry barns (corresponding to 0.2 g of product/m2 of floor surface, according to a specific dose calculation depending on the building type), one day before the animals’ entry and then again after 15 days of animal production to reinforce the presence of beneficial bacteria during the batch. The feeder surfaces were sampled for microbial analysis.

- It was shown that the application of LALFILM PRO led to the implementation of a positive microbial biofilm (significant increase of Bacillus spp. populations) (Figure 3).

- As a result, in the buildings where LALFILM PRO was applied, total loss (culling + mortality) was reduced by 21% as compared to the control buildings.

- By creating positive biofilms, LALFILM PRO helps improve the microbial environment for safe production in poultry barns, as shown by reduced mortality and culling rates.

A scientifically supported concept

An external in vitro study was conducted at the Laboratory of Molecular Epidemiology (LEPIMOL), School of Veterinary Medicine, Federal University of Uberlandia, Uberlandia, MG, Brazil, to study the effect of LALFILM PRO on the recolonization of various microorganisms of concern in poultry farming (Monteiro et al., 2021).

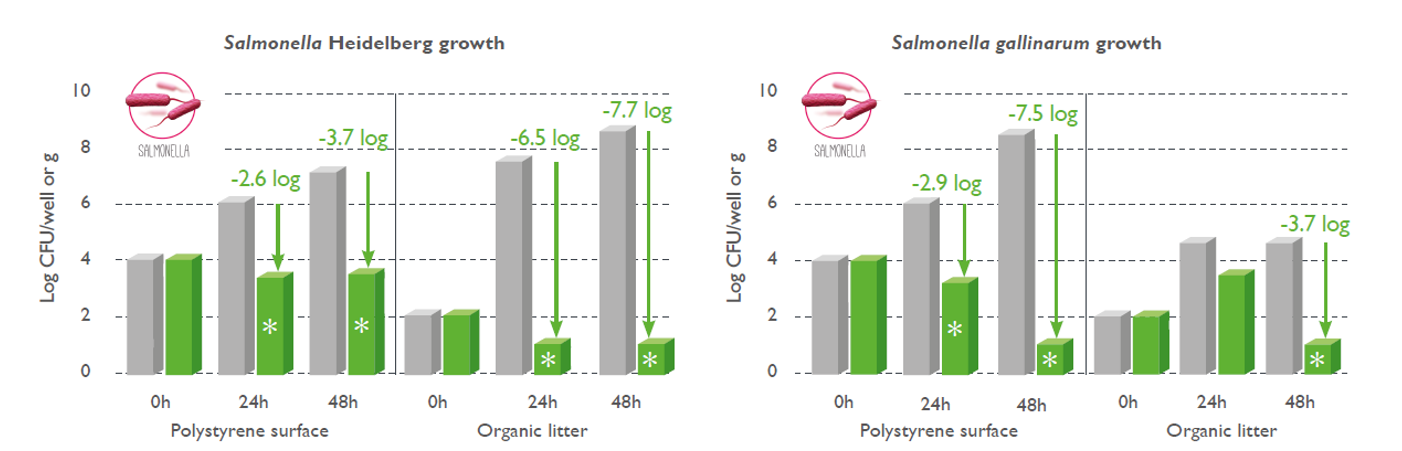

Salmonella Gallinarum (SG), Campylobacter jejuni, Salmonella Heidelberg (SH), and methicillin-resistant Staphylococcus aureus (MRSA) were tested on different surfaces. The SH, SG, and MRSA viability were evaluated on polystyrene surfaces (microplates) and on wood shavings (sterilized organic litter from a chicken farm), to mimic the disinfected surfaces and the clean litter found before the animals entered the building.

In this study, LALFILM PRO was sprayed on clean and sterilized surfaces at 0.1 g/m2, and 24 hours later, the surfaces were inoculated with one microorganism species.

- The two Salmonella species tested had limited growth in all environmental conditions previously inoculated with LALFILM PRO. Significant differences were observed from 24h after the inoculation for all conditions except on organic litter for S. gallinarum where a significant difference was shown at 48h.

- MRSA had limited growth in all environmental conditions previously inoculated with LALFILM PRO. As soon as 24h after its addition, MRSA growth was significantly lower by 3.5 logs on polystyrene surfaces and 1.3 logs on organic litter.

- Campylobacter jejuni was tested on polystyrene surfaces only. It had significantly limited growth on polystyrene surfaces previously inoculated with LALFILM PRO for 48h. Indeed, 48h after its addition, Campylobacter jejuni growth was significantly lower by 1.4 log.

- Colonization by the tested bacteria was limited in all environmental conditions when previously inoculated with LALFILM PRO. Results from these lab trials showed that the positive biofilm created by LALFILM PRO is an effective tool to help reduce the recolonization of surfaces by undesirable bacteria.

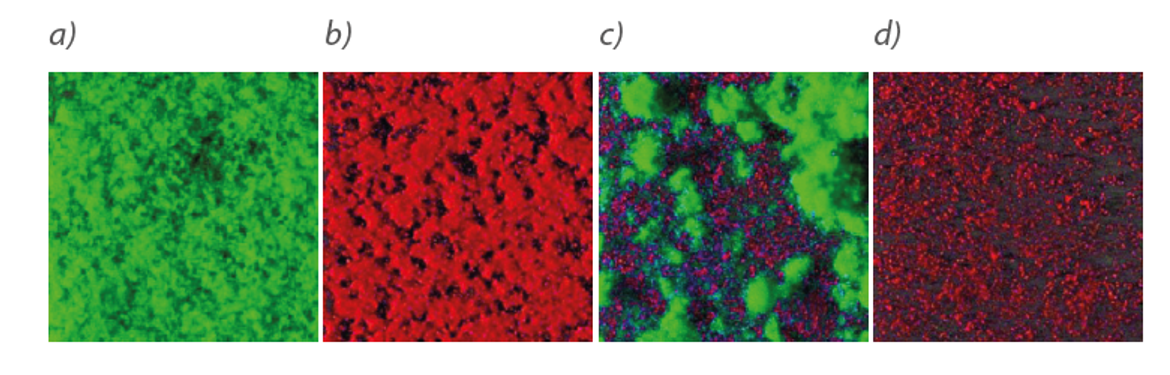

Another external in vitro study conducted by INRA Micalis (Paris) allowed scientists to visualize the interaction between LALFILM PRO positive biofilm and different microorganisms (Staphylococcus aureus HG003, Listeria monocytogenes LO28, Escherichia coli SS2 and Escherichia coli 977 in this case). Coupons were inoculated either with LALFILM PRO or the tested microorganism strain alone (control). 24 hours later, the tested microorganisms were added on top of the LALFILM PRO biofilm. Figure 5 shows one example of the positive and negative biofilms visualization.

Conclusion

Poultry farm biosecurity measures — including cleaning, disinfection, and application of sanitary breaks — impact the level of infection pressure before new animals enter the barn. Integrating a positive biofilm approach is shown to be an effective tool to complement these measures. It helps improve the microbial environment after the disinfection step and during the batch.

In today’s health context, ensuring a safe microbial environment during the whole production cycle is a must, and new approaches to biosecurity that combine disinfection and a virtuous microbial ecosystem management approach are very promising.

Do you want to know more about positive biofilms and their importance in farm building?

To learn more about LALFILM PRO, consult our website: https://lallemandanimalnutrition.com/en/europe/products/lalfilm-pro

| References | ||||

|---|---|---|---|---|

| Monteiro GP, Rossi DA, Valadares Jr EC, Peres PABM, Braz RF, Notário FO, Gomes MM, Silva RR, Carrijo KF, Fonseca BB; Lactic Bacterium and Bacillus Sp. Biofilms Can Decrease the Viability of Salmonella Gallinarum, Salmonella Heidelberg, Campylobacter Jejuni and Methicillin Resistant Staphylococcus Aureus on Different Substrates; Braz. J. Poult. Sci. 23 (02); 2021; https://doi.org/10.1590/1806-9061-2020-1408 | ||||

| Other references are available upon request. | ||||