Managing the Hatch Window

The term ‘hatch window’ is used to describe the time span between the hatching of the first and the last chick in one particular hatcher. However in practice, because it is impossible to look inside each and every hatcher basket without compromising the hatcher climate, the hatch window is estimated rather than measured precisely.If the hatcher has a window, the measurement of the hatch window begins with sight of the first chicks. Another good indication is an increase in relative humidity. Once the first five to 10 per cent of chicks emerge from their shells, the moisture on their bodies quickly evaporates, which drives relative humidity upwards spontaneously.

It is possible to stop and open the hatcher at, for example, 36, 24 and 12 hours before planned chick take-off, to estimate when the first chicks appeared. But this method interferes with climatic conditions, and estimations are often crude, based on observations from a sample of hatcher baskets by quickly opening the hatcher. Using this method, timing the appearance of the last chick will often vary from hatchery to hatchery. And consider too that the last chick may never, in fact, hatch in the case of, for example, an externally pipped egg – complete with a still living, fully developed embryo – that fails to finish the job due to malpositioning.

Chicks do not hatch at exactly the same time. Even if two hatching eggs receive the exact same pre-incubation and incubation treatment, they still may differ a few hours in incubation time because of natural variation in embryonic development. In normal day-to-day practice, eggs placed together in one particular hatcher almost certainly do not have the same history. Factors like egg size, flock age, post-lay egg cooling profile and storage times do all have an effect on incubation time.

The most crucial factor for the rate of embryonic development – and thus determining incubation time – is temperature. The hatchery manager must ensure that hatching eggs have the same or very similar characteristics before placing them in the incubator. Once inside, uniform conditions, especially uniform temperature distribution, are essential to achieve a short hatch window.

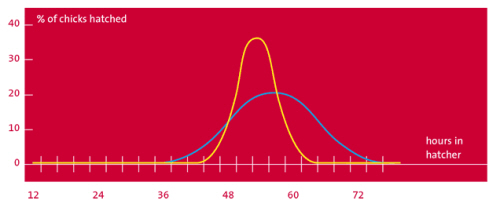

With good management and modular, single-stage equipment, it is possible to achieve a hatch window of 12 to 24 hours for broilers. In any case, the hatch window should not exceed 24 hours (see figure). This prevents dehydration in chicks that hatch first. Subsequently, ensuring that all the chicks – from first to last in the hatch – gain access to their first feed at the same time or as closely as possible to simultaneously, is important for maintaining post-hatch uniformity. Careghi et al. (2005) showed that delaying access to feed after the hatch depresses the relative growth rate of chicks differently for early versus late hatched chicks.

When using modular single-stage incubation methods, the hatch window for commercial layers is usually even shorter than for broilers, at just eight to 12 hours.

Advice

- Fill the setter with similar batches of eggs pertaining to breed, maternal age, egg size and storage time.

- Transfer batches of eggs from one big setter to several smaller hatchers, keeping each batch with similar characteristics within one hatcher.

- Pre–heat eggs for five to eight hours at 25°C (77°F) in the setter. Alternatively, pre-warm eggs in the setter room for a minimum of 12 hours to ensure uniform internal egg temperature prior to the onset of incubation.

- Ensure fast, even warm-up to incubation temperature by using setters equipped with sufficient high heating capacity. Incubation set point should be achieved within five to six hours, providing eggs are properly pre–heated or pre–warmed.

- Aim for uniform incubation conditions, especially temperature. This is best achieved in modular single-stage incubators, designed for uniform temperature distribution, with the functionality to deliver different temperature set points per batch of eggs.

April 2012