One Producer's Journey to Next Generation of Layer Housing

A Canadian egg producer explains the challenges and rewards of building a furnished cage system for his organisation's hens.Egg farmer Levi Hofer of Lethbridge, Alberta, is like a lot of today's poultry producers – he has one eye on the present and the other on the future.

Like others in his industry, he has an opportunity to change his production system as part of normal business practices. In Mr Hofer's case, at least some of the production facilities at the New York Hutterite Colony where he is egg flock manager were starting to age, so replacement or updating needed to be considered. But that needed to be done in a way that meets consumer and industry demands.

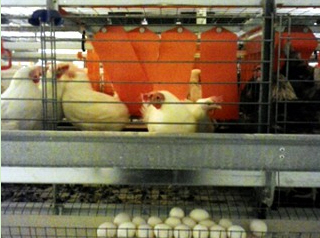

As of 2014, layers at the Colony are housed in new state-of-the-art facilities called 'furnished housing'." It is a new style that moves on from conventional cage housing and provides a more natural open environment, with nesting areas, scratch pads and perches.

Search for the Leading Edge

The egg barn in the Colony's system, a conventional cage system, was built in 1994. But it was beginning to show its age and like any system, time and cost of maintenance raised the obvious question of whether to repair or replace with a new system.

The Colony team decided to take a long hard look at their options. In fact, they invested more than four years into system research before making their final choice.

Starting point was to understand all the options. They began with their own producer association, the Egg Farmers of Alberta, which had developed recommended production standards. Next, they contacted representatives of the major chicken housing equipment in the province.

Along the way, they decided they wanted to salvage the barn structure. That concrete and wood framework had been well designed to last 50 years, so it had many years left in it. Retaining it would reduce the costs of transition significantly but, like any renovation, fitting a new system into an existing structure took more planning.

Mr Hofer explained: "Our ultimate goal was a system that would last 30 years. We determined there were benefits to free-range, free-run or enriched or furnished systems but we decided we needed to see those systems in action to fully understand them."

Equipment suppliers were able to show them operating systems in all categories. Examples of most were in Alberta but the furnished housing system was new enough that they needed to visit an operation in the US.

In the end, the Colony team decided the furnished housing system best met their needs, and that the equipment supplier who had provided their original equipment had their confidence.

Adapting Technology to New System

Once the system choice was made, implementation was the next step. The layer barns were shut down for four months and gutted, and the new system installed.

Mr Hofer's belief is the Colony now has met its objective of having a system that will meet production standards for the next 30 years.

However, like any new system, adjustments have been required. For example, it has taken constant management to have birds properly use nesting, feeding and perch areas. At the start, for example, birds stayed in the nesting area because it was comfortable and that produced some fighting. This required adjustments to feeding and lighting to encourage birds to move out of the nesting area to the scratching area.

Each adjustment takes about eight days to see the results, so it takes time to get it running well, said Mr Hofer. But while the system is in its early stages and still going through its orientation, the overall performance signs are positive.

Satisfaction of a Good Decision

Mr Hofer, like many producers, has a management approach that includes a regular routine of close checking of the flock. One example is that during the transition stage, he went back into his barn after the lights were out with a blue flashlight, roaming the barn passageways, looking in at the birds and seeing how comfortable they are.

"They were nice and comfortable," he said. "Every bird was on a perch for the night just as they would be in a natural environment.

Mr Hofer added: "As a manager I love it because I can communicate with my flock by adjusting the tools of producing an egg – feed, water, humidity, air quality, lighting. I can talk to those birds and they can talk back to me. For example, we use the lights to mimic sunrise. The lights come on slowly and give birds a chance to wake up. They relax better that way and that ultimately produces a better egg."

Built with Consumers in Mind

At the end of the day, Mr Hofer's team knows there is a premium, perhaps as much as 20 per cent to install this new systems but he also knows it appeals to the consumer.

Mr Hofer added: "Keeping the consumer and the distributor happy was a very big factor in choosing and building this barn.

"We need to be thinking how we can communicate with the consumer. We need the consumer to walk up to the egg shelf in the grocery store and look at the options and see choices like the furnished housing system."

This article was first published by Meristem Land and Science.

July 2014