Poultry dust – It's impact on bird health

Learn what makes up poultry dust, how it can affect bird health, how it affects ventilation systems, and how to measure airborne dust levels in poultry housesPoultry houses sometimes contain high concentrations of airborne dust. Prolonged exposure to high levels of dust can cause health problems for human workers as well as for birds that live in the facilities 24 hours a day.

Poultry dust is particulate matter consisting primarily of manure, feed, feathers, dander, litter, and a lot of biological contamination. Dust also contains inorganic particulates from building materials such as concrete or insulation used in barn construction. Due to their irregular shape, these particles offer a tremendous surface area for binding bacteria (or their components), viral particles, and mold.

Dust size is important. Larger dust particles tend to settle from air close to their source. Smaller dust particles stay airborne for much longer, making them more likely to be inhaled with the air.

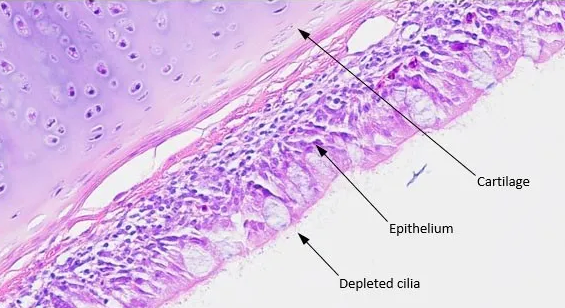

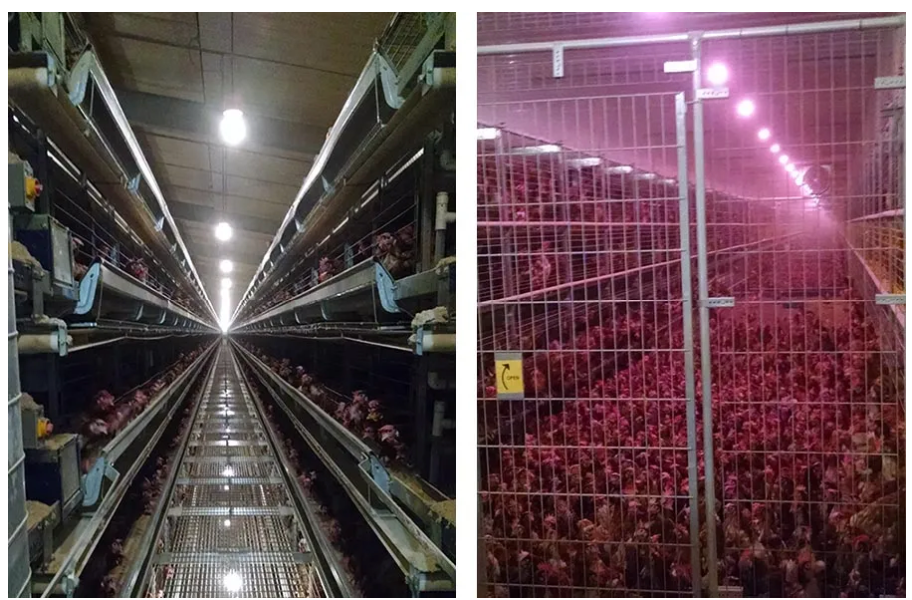

Airborne dust levels in some poultry barns can occasionally be high enough to produce a visible haze, making it difficult to see from one end of the building to the other in very long barns.

Dust can be categorized as inhalable or respirable. Inhalable particles are those that are small enough to inhale, yet they typically get trapped on the mucosa of the upper respiratory tract, like the one surrounding the nasal turbinates, trachea, or large bronchi. For humans, this consists of particles smaller than 10 microns (µm) in diameter (PM10).

Respirable particles in humans are typically smaller than 2.5 µm in diameter (PM2.5) and may travel deep into the lungs all the way into the gas exchange surface (alveoli). In poultry, particles of 2.5 µm in diameter are able to reach very deep into the parabronchi and air capillaries, which are the structures where gas exchange takes place.

Effects on employees and birds

Excessive levels of dust pose a hazard to human workers as well as to birds living in the facility. Human workers can be protected by using appropriate and fitted dust masks and respirators. But the birds that live in the facility 24 hours a day have no protection. High levels of airborne dust can lead to increased mucous production and conjunctivitis in poultry due to inflammation of the airways and eye membranes.

Inflammation of the upper respiratory system is strongly associated with the development of micro lesions that can easily get contaminated with viral particles or bacteria, which very often are on the surface of the dust particles. Thus, the dust particles serve to inflame the airways, making them more susceptible to infection by opportunistic pathogens, and to carry the pathogens to the respiratory surfaces.

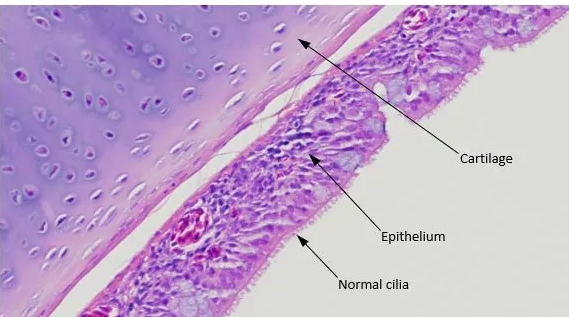

Cilia are the structures responsible for removing dust and mucus from the trachea and bronchi. Dust in combination with ammonia gas reduces the ability of the cilia present in the trachea to quickly remove foreign particles trapped in the mucus.

Gross differences can be seen when comparing magnified photographs of a normal trachea (Figure 1) and the trachea of a bird that has been exposed to 50 ppm of ammonia gas and airborne dust for 5 consecutive days (Figure 2). In Figure 1, the cilia of the epithelial cells are intact. But in Figure 2, the cilia appear to have been partially depleted. When cilia are damaged, airborne particles can remain in close contact with the respiratory epithelium for a prolonged period of time. Thus bacteria, viral particles, fungi, and toxins have a greater opportunity to either invade the respiratory epithelium or to cause inflammation of the upper respiratory tract.

If the challenge of ammonia and dust is severe it will produce variable levels of inflammation in the respiratory tract. Inflammation damages the airways and renders birds more susceptible to challenges with viruses and bacteria that are normally present in poultry houses. As a consequence, diseases that are normally benign can have a much more severe outcome resulting in premature mortality or condemnation at the processing plant.

Dust accumulation on building surfaces

Dust accumulation on ventilation shutters (Figure 3a) and fan blades reduces ventilation performance. Shutters weighted down with dust will increase the static pressure that ventilation fans must overcome and decrease barn ventilation air flow significantly (Fabian, 2016). Dust also accumulates on wire dividers (Figure 3b), which will reduce air flow through the building if the buildup is severe. Dust is also carried outdoors where it can be a nuisance/concern for neighbors. This can be mitigated by using vegetative buffers (Patterson, 2014).

How do you measure dust?

Fine particulates in the air can be measured using gravimetric sampling methods that weigh the particles or in real time with optical particle counters. Gravimetric sampling uses small pumps to draw air through filter paper discs and trap airborne dust particles larger than the filter pores. It takes several hours for a sufficient quantity of dust to settle on the discs, so this method does not provide real time measurements. After sampling, the discs are weighed to determine the mass of accumulated dust. The average airborne dust concentration is calculated from the mass of settled dust, sampling pump air flow rate, and duration of sampling time.

Optical particle counters work by measuring the amount of light that passes through a sample of air containing dust in real time. They typically work on the principle of light scattering. An air sample is drawn into a sample chamber by a small fan or pump at a constant air flow rate.

A high intensity light, commonly emitted by a laser diode, is directed into the chamber. Airborne dust particles that enter the chamber scatter the light, and a detector in another part of the sample chamber measures the intensity of the scattered light. Dust particle size and count are determined from the amount of scattered light that is measured by the detector.

Optical particle counters are typically calibrated using spherical particles of standardized test dusts. Since poultry dust is not typically spherical in shape, optical particle counts can be less accurate than gravimetric samplers, but still useful for establishing a baseline dust level and making comparisons over time. Figure 4 shows a handheld airborne particle counter measuring airborne dust.

Consumer grade optical particle counters have become affordable in recent years ($100 to $500), making it possible to measure dust concentration at fixed locations. Industrial handheld optical particle counters have a higher cost ($2,500 or higher) but generally provide more features, better accuracy, and may be available with traceable calibration certificates. Optical particle counters require periodic maintenance (i.e. cleaning dust deposits and ensuring a clear optical pathway for the air sample) and calibration to maintain accuracy.

Sometimes fine level quantification of the amount of dust suspended in the air is not really needed to determine that you have a problem in a barn. Usually poultry houses are quite long, and simple observation may be enough to determine the extent of the problem. If you look to the end of the barn you should be able to see clearly past 100 feet (Figure 5a). If you see a cloud of dust instead of chickens (Figure 5b), you can be sure that dust is above optimal levels.

You may also be able to see airborne dust by shining a bright light source such as a flashlight and viewing the air in front of the light at an angle. If the air appears hazy or you can see a large number of dust particles, such as in Figure 6, you likely have a dust problem.

How do you characterize dust?

Dust is seldom uniform; it is made up of many different organic and inorganic materials of different shapes and sizes. A dust sample can be sent to a laboratory for analysis to determine its makeup. The particle size distribution tells what percentage of each particle size is in the sample and gives an idea of the relative coarseness of the dust.

Coarse dust tends to settle more rapidly, while fine dust may remain suspended in the air for longer periods of time. However, depending on material density, there may be coarse particles that float or fine particles that settle more rapidly. Fine dust also travels farther into the lungs than coarse dust, making it more hazardous to inhale. Dust particles smaller than 1.1 µm (David et al., 2015) can reach deep into the airways of the lungs of the birds (and humans), carrying pathogens with them.

Summary

High levels of indoor dust are problematic for both worker and bird health and can cause challenges for building ventilation systems. If you have a dust problem in your poultry facility, the first step is to determine where the dust is being generated. Simple observation may help you identify the source. There are multiple dust sampling methods you can use to quantify the severity of the dust problem and to measure the effectiveness of steps you take to mitigate airborne dust and improve indoor air quality in your barns.