Reducing the dust load, protecting the health in layer houses

The ban on layer cages was important to improve animal welfare, but it also caused dust formation issues to return.by Dr. Ralf Kosch, Big Dutchman International GmbH

The changeover of egg production to cage management systems with manure belt ventilation in the 1970s, a then very progressive step, significantly improved hygiene and the entire environment in the barns. This was due to the fact that the birds’ manure was collected on manure belts, dried and then removed from the house at regular intervals of approximately three or four days. Apart from ammonia emissions, the dust concentration in the air was much lower, since there was no litter inside the houses.

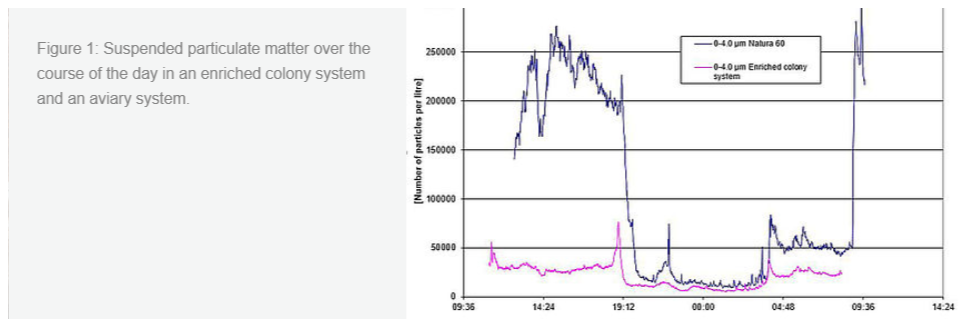

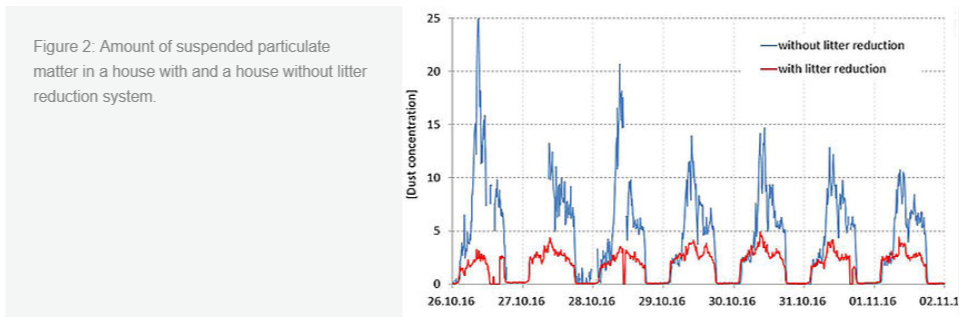

The ban on layer cages was important to improve animal welfare, but it also caused dust formation issues to return. A comparison of continuous dust measuring very clearly indicates the difference between the management systems (fig. 1).

Dust concentration heavily depends on the management system and the time of day, i.e. the birds’ activities. Before the lights are switched on and before feeding starts, dust concentration rises abruptly, while it is hardly possible to measure any particles during the dark phase. The number of particles for enriched colony systems did not exceed 6,000 particles per 100 cm³ of air, whereas 60,000 particles per 100 cm³ were measured in an aviary house. Dust concentrations in aviary houses at the above mentioned times of day can be as high as 20 mg/m³.

Dust irritates the lungs

High dust concentrations have harmful effects on the health of both humans and birds. This is because part of the very fine particles, i.e. inhalable and respirable suspended particulate matter (PM10), can reach the lung’s alveoli. This particle size can cause irritation and inflammation in the lungs. Exposure to bacteria or health risks as we see them in the so-called “farmer’s lung”, which is caused by fungi or endotoxins, has not yet been detected due to dust arising from litter. Risk assessment for suspended particulate matter must therefore differentiate here. The TLV (threshold limit value) for inhalable dust is currently 10 mg/m³ (according to the German Technical Rules for Hazardous Substances (TRGS) 900). In case of an extended stay in a house during the birds’ activity phase, wearing dust masks is recommended.

Source of dust formation

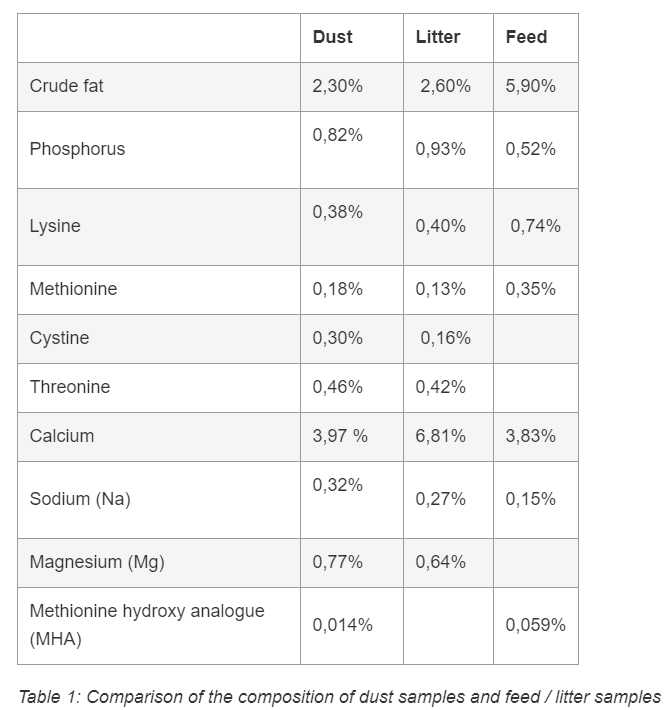

The main source of dust emissions in aviary houses is the litter. Besides the comparison of management systems with or without litter as mentioned above, this can also be proven by comparing the litter’s components. An analysis of selected components of dust, litter and feed from a layer farm shows that the components of the dust samples are nearly identical with those of litter (table 1). However, the dust also contains traces of hydroxy analogue of methionine, whose only possible source is feed.

Litter management

To better understand how dust is created from litter, it is worthwhile to take a closer look at how litter is currently managed in layer houses.

When the hens are moved into the barn, only very little material (100 to 300 g/m²), for example wood chips or pellets, is spread as litter. For the night, the layers move into the higher aviary levels to rest there. Approximately two thirds of the manure can thus be collected on manure belts and transported out of the house regularly. About one third drops down into the litter.

This litter layer slowly builds up in height over the course of the batch. Since the hens are constantly active in the litter, its particles are ground finer and finer until they are so small that they are suspended in the air as suspended particulate matter. More dust forms the longer the litter stays in the house. There is a number of factors that support increased litter drying and the abrasion of litter particles, which consequently causes the formation of dust.

House air

Due to the requirements of the German Order on the Protection of Animals and the Keeping of Production Animals (4.5 m³/kg h), current ventilation systems in layer houses are twice as large as required by DIN 18910. The air change rate is very high with eight to ten changes per hour. As layers emit very little water into the air, the warmed air has very good drying properties, with an only slightly increased water content. With current housing systems, the cold and humid fresh air does not directly reach the litter, i.e. it does not immediately condense in the litter. Negative pressure ventilation systems with fresh air inlets located in the side walls create a jet of air that passes the entire management system until it reaches the centre of the house at a pressure difference of 10 to 40 Pa. This way, the air is warmed first and only then reaches the area close to the floor. With a smooth, barrier-free ceiling, the fresh air can flow continuously along this surface (Coand? effect).

Houses with pop holes use equal pressure ventilation. Most often, fresh air chimneys are installed. An integrated fan brings fresh air into the house evenly and along a horizontal air direction plate, thus causing the air to circulate, starting from the centre of the house. With an advanced stage of fresh air chimneys, warm house air is drawn into the chimney through a gap and then mixed with fresh air. This means that even low air volumes create mixed air that actively stirs all air in the room.

Drinking water

Another cause for very dry litter can be that the layers consume very little water. In general, laying hens should drink approx. 225 to 250 ml per day each. Consumption should never be much higher or lower than this quantity.

In modern and well-insulated houses, the mentioned factors have moreover ensured that litter stays dry and crumbly. Humidity is removed from the fresh manure lumps, similar to cat litter. This is beneficial to the birds’ feet and their activity and therefore requested in modern egg production. The increased formation of dust is a disadvantage.

Technical measures for dust reduction

The following sections present four technical measures that contribute to dust reduction when combined with other technologies. In general, these measures aim at reducing the amount of manure becoming part of the litter and at avoiding the formation of very fine particles.

Litter reduction:

Continuous and, if possible, automatic litter reduction can effectively reduce the formation of dust. Instead of the emitting surface, the share of older particles in the litter which turn into dust first is reduced. A study compared two identical layer houses with Natura Nova aviaries; one of the houses had a litter reduction system, the other did not. Without litter reduction, the litter layer was up to 12 cm high by the end of the batch, while the house with litter reduction system only had a layer height of 2 to 3 cm. Figure 2 shows the dust concentration in both houses, with and without litter reduction system. The effect of dust reduction is clearly visible for the second half of the batch. The amount of dust in the house with litter reduction was reduced by an average of 42 percent. The amount of litter was reduced to a quarter. Even if the emitting surface is not modified despite the litter reduction system, the potential for dust emission is significantly reduced, since older particles that first turn to dust are extracted from the house continuously.

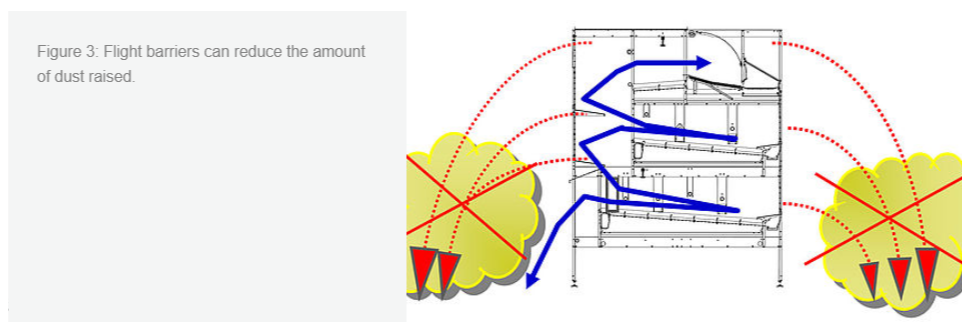

Flight barriers:

Layers fluttering down into the litter from the upper tiers of the aviary raise large amounts of dust. There are aviary systems available that can only be reached from the bottom tier and that have flight barriers in the upper tiers (fig. 3). Aviary systems that are only accessible from the bottom tier show dust emissions reduced by 70 percent (VDI 3894). In these systems, the birds cannot fly down from the top aviary tier into the litter and thus do not raise as much dust. Such management systems did not become a standard in Germany, however, since they can also be used to close off access to lower levels entirely. The reason for this design is that pullets should have the chance of getting to know the management system after moving in, and easier bird inspection. Although this is is allowed for up to three weeks after moving in according to the German Order on the Protection of Animals and the Keeping of Production Animals, it was not popular among supervisory authorities, since they presumed that producers kept the system permanently closed. It should be noted that this type of management system allows influencing the activity and movements of the birds, and thus reduces dust emissions.

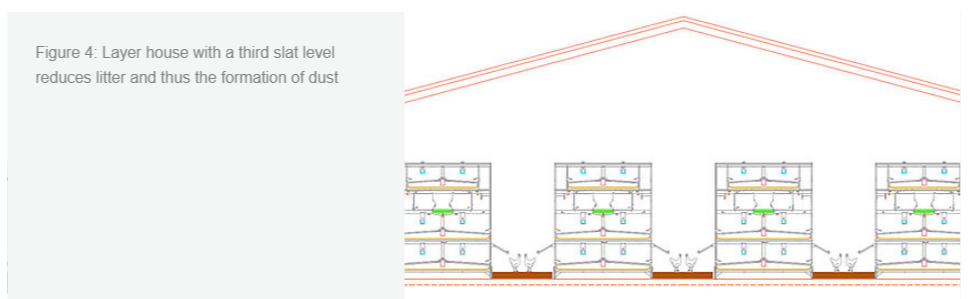

Smaller litter areas:

In general, 100 percent of the house floor is littered, i.e. it can be counted as usable area. To utilise the house surface optimally, the planning stage calculates with 9 birds/m2 in the management system, and the same number of birds on the house floor. This way, the building can house 18 birds/m2, as permitted in Germany, while half of the usable area is counted as litter area. The German Order on the Protection of Animals and the Keeping of Production Animals, however, requires that one third of the house surface or at least 250 cm2per bird must be litter area to allow the layers to scratch and to take dust baths. To keep the littered area as small as possible, with the goal of producing only a low amount of suspended particulate matter, 45 percent of the house surface would be enough to meet the conditions of the German Order on the Protection of Animals and the Keeping of Production Animals. The decreased percentage of litter significantly reduces the area that emits dust. Figure 4 shows an example plan of a layer house with a third slat level with manure belt installed above the house surface area.

Humidification of litter:

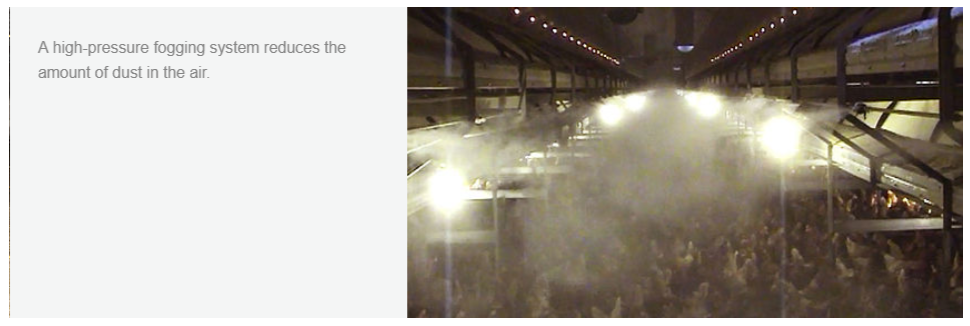

In case of very dry litter, it may be useful to bind suspended particulate matter by means of a high-pressure fogging system. Such a system must be able to create very fine droplets (2-5 µm) to keep the water in the air for as long as possible. Humidification also moistens the surface of the litter and thus prevents suspended particulate matter from suspending into the house air. Finding the correct dosing, however, is not easy. Too much humidification can cause an increased release of ammonia if the water content in the litter is available for enzymatic conversion of nitrogen. Moreover, the management system components can get moist, which can lead to corrosion.

Conclusion:

As a summary, it may be stated that many animal welfare goals have been reached by the decision for barn egg production and free range egg production.

For the resulting higher amount of dust, different technical approaches are available today. They must be pursued consequently in practice, building on the knowledge gained in the past years.

Scientists and lawmakers are now called upon to deal with the consequences and conflicts of interest caused by management regulations mainly aimed at animal welfare.