Utilizing a consistent protein ingredient in poultry dietary formulations

Soybean meal (SBM) is the primary protein source utilized in poultry diets due to its highly digestible amino acid profile and favorable availability with 200-250 million metric tons produced annually. Soybean meal is a by-product derived from one of three main processes to extract the oil of soybeans. These processes include solvent extraction, mechanical extraction by screw press (expeller SBM), or a combination of the two. However, nutritive value of the final SBM product can vary depending on the oil extraction process used, as well as the composition of the initial raw soybean source.A few factors contributing to the variability observed in SBM include geographical origin of the soybeans, soil type, environmental conditions during planting, growing, and harvesting, and storage conditions. Due to the level of SBM included into poultry diets and large volumes of feed manufactured, it is extremely difficult to analyze each incoming batch of SBM and accurately use determined nutrients for each corresponding batch of feed. Therefore, poultry nutritionists commonly use estimated crude protein and amino acid content of SBM to formulate diets. By doing so, batch to batch SBM variation causes feed formulations to be less reliable and presents the threat of over- or under-formulating protein in the diet. As SBM can sometimes reach more than 30% of the diet, any inaccuracies in formulating protein equates to unwanted costs for the nutritionist.

It is also important to note that SBM contains considerable amounts of anti-nutritional factors (ANFs) that can limit dietary nutrient utilization having a detrimental effect on poultry health and growth performance. Similar to the chemical composition, significant variation in ANFs may be observed regardless of geographical and environmental conditions. Garcia-Rebollar et al. (2016), observed variation (CV %) in the major soy-ANFs trypsin inhibitor, stachyose, and raffinose to range from 18.9-22.1%, 8.4-10.1%, and 14.2-25.9% respectively, across SBM samples from USA, Brazil, and Argentina (Table 1).

Table 1. Content and variation (CV%) of anti-nutritional factors in soybean samples from three different geographical locations (adapted from Garcia-Rebollar et al. 2016).

USA (n=180) |

BRA (n=165) |

ARG (n=170) |

||||

Range |

CV (%) |

Range |

CV (%) |

Range |

CV (%) |

|

TIA (mg/g DM) |

1.4-5.5 |

22.1 |

1.8-4.7 |

18.9 |

1.4-4.6 |

20.2 |

Stachyose (%) |

4.32-8.26 |

8.4 |

3.65-7.34 |

10.1 |

3.73-7.10 |

9.5 |

Raffinose (%) |

0.6-1.86 |

25.9 |

0.9-2.57 |

17.2 |

0.9-2.01 |

14.2 |

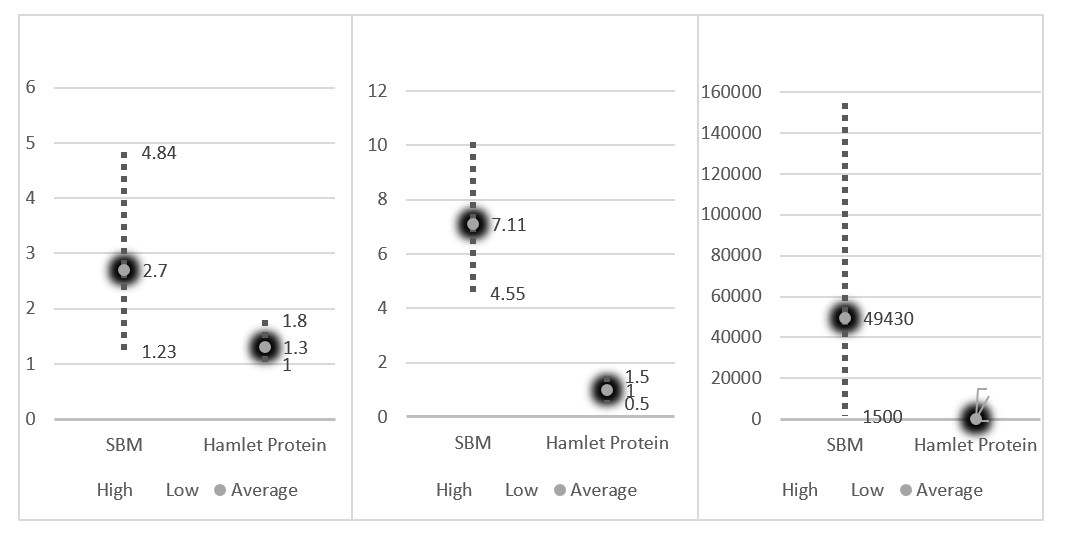

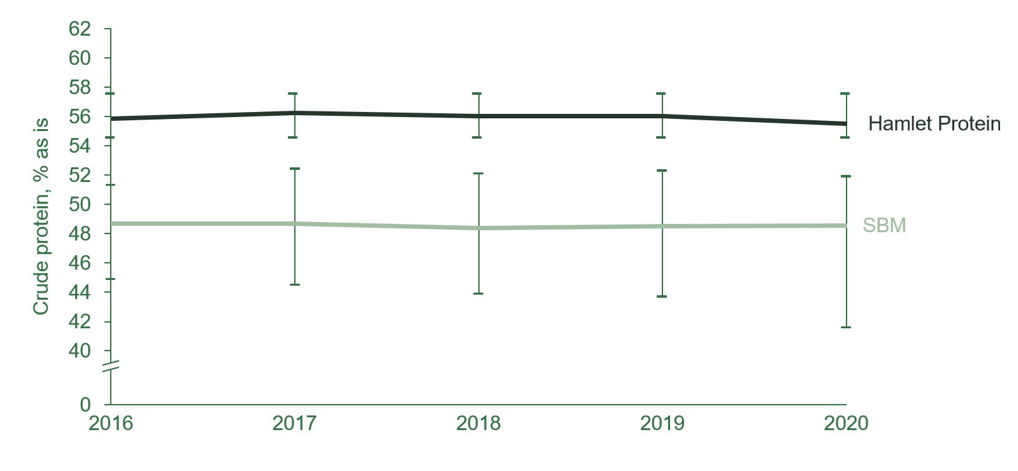

These variation concerns can be reduced by further processing SBM into a specialty protein ingredient with the same consistent protein content regardless of geographical origin, growing conditions, or other seasonal variations. At Hamlet Protein, a patented enzymatic processing method is used to significantly reduce the amount of undesirable ANFs in SBM and reduce the variation in protein content to an absolute minimum regardless of the raw material (Figure 1 and 2). Other further processing techniques utilize high temperatures or prolonged heating to lower dry matter and increase SBM protein content which increases the chance of protein denaturation or unwanted Maillard reactions. Throughout the process at Hamlet Protein, enzymatic treatment prevents the need for excessive heating and ensures consistent protein content without impacting the amino acid profile.

Any variability in the actual nutrient content of the ingredient and the nutrient values utilized in formulations will not only limit the nutritive value of the diet but may also affect feed efficiency and growth performance of the animal if the variations are large enough. This concept is especially important in young poultry nutrition as they are still physiologically immature and have relatively high protein and amino acid requirements. Gut health development and digestive physiology, growth performance, and immunity can all be influenced by the characteristics of feed ingredients used (Beski et al., 2015). The inclusion of a consistent, high quality protein ingredient can alleviate concerns around SBM variation and ensure the finished diet’s nutritive value corresponds with what the animal is consuming.