Why It Is Beneficial to Pre-heat Multi-stage Setter Egg Sets

Pre-heating of multistage egg sets before the onset of the incubation process is important to achieve a uniform hatch windows of short duration, according Ecuador-based Poultry Hatchery Specialist, Angel Salazar.Multi-stage incubators are dependent on the efficient transfer of metabolic heat from the embryos right at the end of incubation to those at the very start of the incubation process.

In a multistage incubator, eggs are usually set and transferred twice on a weekly basis. It is important that similar numbers of eggs at each stage of the incubation process are placed within the incubator cabinet and that these stages of incubation are evenly distributed across the incubation period.

The traditional method used in many broiler hatcheries to raise the internal temperature of the egg mass prior to setting in multistage incubators, has been to 'acclimate' these eggs for a period of eight to 10 hours in setter trolleys placed in the setter room hallway. This way of accomplishing this goal lacks precise control of ambient conditions and takes place over a long period of time. It leads to a non-uniform raise in internal egg temperature and a hatch window of long duration. Last but not least, carrying out this process of acclimating eggs sets in setter hall corridors increases the risk of moisture condensation on egg shells.

The internal egg temperature distribution of 'acclimated' egg sets lacks the needed uniformity to be able to start most of the eggs at a similar internal temperature once placed inside the setter cabinet to start the incubation process itself. That is why pre-warming/heating of the egg mass when carried out under a controlled set of ambient conditions accompanied by forced air and heat sources is a much better proposition. Thus, true pre-warming allows for the entire egg mass to be placed in multistage incubators to reach a relatively quick and uniform increase of internal egg temperature to a range of about 26 to 28 degrees Celsius before placing the eggs in the multistage incubator.

The author is convinced pre-heating of multistage egg sets before the onset of the incubation process, for block setting or in fixed rack units, is a very important and contributing factor in achieving uniform hatch windows of short duration.

Pre-heating is routinely achieved in single-stage incubators during the pre-warming step of the setter incubation profile. The aim in the multistage hatchery should be to allow for a uniform, similar starting point, e.g. internal egg temperature, for the great majority of the 'reactivated' embryos.

Without the benefit of pre-heating, multistage egg sets do exhibit greater eggshell temperature variation even after several hours of incubation inside the multistage setter cabinet. Further, pre-warming is also beneficial in reducing early embryo mortality, especially before and during the blood ring stage at three days into the incubation process.

A good rule of thumb is to provide 4,000 watts of heating capacity for each 30,000 to 32,000 eggs to be pre-warmed during a period of five to six hours.

There are several types of pre-heating chambers available in the marketplace. Some of these combine both hot water – at 80 degrees Celsius - inside copper coil assemblies and, electric heat generated by heating elements. This allows for a quicker and more energy efficient pre-heating procedure.

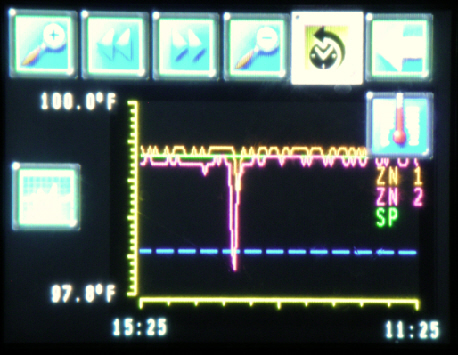

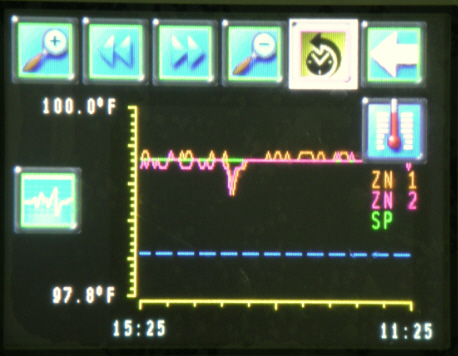

The table below illustrates a pre-heating schedule that has worked quite well for eggs that have been in storage for five to seven days at temperatures in a range of 18 to 20 degrees Celsius.

| Egg quantity | Heating capacity | Air movement | Duration | Goal |

| 100,000 eggs | 6,000 watts | (6) Fan motors @1,750RPM |

5.5-6.0 hours | Air temperature in the pre-heating chamber/room @ 100°C or 37.8°F |

When the air temperature reaches desired goal of 37.8 to 38.0 degrees Celsius, the internal egg temperature will be in a range of 26 to 27 degrees Celsius.

When the multistage setter is loaded with eggs preheated this way, there should not be any measurable temperature drop inside the setter cabinet.

The pre-heating chamber should be closed to the outside. There is no need to implement egg turning or to add moisture in the pre-heating chamber/cabinet. Only two things are required: the heat source and the forced air movement. The easiest way to implement the procedure successfully is to use idle multistage setter capacity as pre-heating cabinets.

Remember, the key concept here is pre-heating of eggs prior to setting can be done in a quick and uniform fashion. Acclimating of multistage egg sets in setter hall corridors takes a long time and the internal temperature rise achieved this way is not nearly as uniform.

July 2014