Helix: Local Exhaust Air Cleaning System By Big Dutchman

GLOBE - Simple and economical retrofitting of exhaust air chimneysEspecially in regions with a high livestock density, farm expansions often receive a building permission only on the condition that the installation of an efficient exhaust air cleaning system is planned. This is often required for the new building, sometimes for any existing buildings and quite often even for all buildings on the farm.

The following problem might arise: traditional exhaust air cleaning systems with more than one cleaning stage can usually only be operated sensibly, if the required ventilation technology is already designed in the form of a so-called central exhaust air system. The entire exhaust air of the barn has to be guided to one central point where the exhaust air system has to be erected in a separate building. However, such a solution is not always possible.

With its new local exhaust air washer system “HelixX” the company Big Dutchman now introduces an interesting possibility to retrofit existing barns with an air cleaning system easily and economically.

The concept already has a European patent pending and will save the farmer high investment costs for a new ventilation system or a completely new additional building since HelixX can simply be installed in the already existing exhaust air chimneys.

Another advantage of HelixX is that it does not require any packing material, which means that no additional pressure increase is necessary which in turn cuts operating costs. In case of a HelixX D65/82, with a flow rate of 10,000 m³/h pressure lies at approx. 30 Pa. Traditional washers range somewhere between 80 and 150 Pa (!)

As no packing material or trickling filters are required, there is no danger of blockage of the filter medium by solid particles.

By the way: in case of power failure, HelixX provides “emergency ventilation” thanks to the natural thermal current of the exhaust air chimney. This is a truly unique function for an exhaust air washer!

First results impressively demonstrate the efficiency of the HelixX-system. Regarding a reduction of ammonia, first tests have already shown an efficiency of up to 70%. And even odours could be reduced by up to 60% through an addition of components to the wash water.

„As soon as these results are validated by long-term measurements, we will carry out further field tests in the market“, says Big Dutchman product manager Andreas Kerssens. The next goal of the Big Dutchman developers is to receive the special DLG certificate (German Agricultural Society)

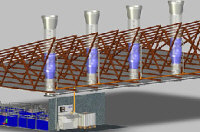

The installation of the newly developed system is relatively simple. Helix consists of a nozzle holder above a helix. Through the nozzles water is sprayed onto the exiting exhaust air thus binding dust, ammonia and odour-carrying agents.

The decentral HelixX units are all connected to each other and then connected to the central water treatment basin. The wash water is conditioned, that means sulphuric acid and / or odour-reducing additives are added to the wash water.

Every HelixX works for itself. This way, operating costs, especially power costs for circulating the wash water, can be reduced to a minimum.

A discontinuous filtration of the wash water into a separate waste store ensures that the waste-concentration in the wash water remains low.