Teaming Up to Fight Biofilm Food Contamination

US - A former Agricultural Research Service (ARS) scientist and a private company worked to develop a new chemical formulation that could help meat processing plants keep work surfaces free of contamination.

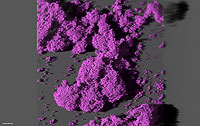

[Image courtesy of MSU Center for Biofilm Engineering, B. Pitts]

Prior to her retirement, microbiologist Judy Arnold worked at the ARS Poultry Microbiological Safety Research Unit in Athens, Georgia. In cooperation with Sterilex Corp. of Owings Mill, Maryland, she tested the company's proprietary formulation for controlling biofilms that contain the foodborne pathogen Listeria monocytogenes. This organism, which can contaminate some ready-to-eat meats, causes serious illness in about 2,500 people each year, resulting in 500 deaths.

Biofilms are protective layers of proteins and polysaccharides that surround bacteria and stick to equipment surfaces. These protective shields trap spoilage bacteria and other pathogens that contaminate food during processing, and they resist cleaning and sanitizing. Longer production runs provide more opportunity for biofilms to establish themselves, and today's longer shelf life adds to the risk of contamination, according to Dr Arnold.

In studies, Dr Arnold found that Sterilex's proprietary formulation appeared to be a cost-effective disinfectant for use in environments for poultry and meat production and processing. The formulation uses multiple chemical and physical actions to penetrate a biofilm, kill the microorganisms, and remove the biofilm from surfaces.

Dr Arnold's results show that the formulation was 100 per cent effective, providing total kill and more than 90 per cent biofilm removal. This disinfectant, according to Arnold, is more effective than currently used disinfectants in reducing L. monocytogenes biofilm growth. These test evaluations also resulted in instructions for use that will meet US Department of Agriculture "zero tolerance" regulations for L. monocytogenes.

Though L. monocytogenes is killed by cooking or pasteurization, it can survive many chemicals used during processing. The pathogen's ability to grow at low temperatures may allow its growth in or on raw or improperly processed, ready-to-eat foods even when they are refrigerated.