Nutriad Concludes 2016 Polish Maize Mycotoxin Survey

POLAND - Poland is one of Europe’s biggest grain producers and the farming sector has changed dramatically since it joined the European Union (EU) more than 10 years ago.Poland is also known to be a major agricultural country with maize planted over approximately 700,000 hectares making it one of the main seed importing countries in Eastern Europe.

Mycotoxins are secondary metabolites produced by filamentous fungi that cause a toxic response (mycotoxicosis) when ingested by higher animals.

Fusarium, Aspergillus, and Penicillium are the most abundant moulds that produce these toxins and contaminate human foods and animal feeds through fungal growth prior to and during harvest, or during (improper) storage (Bhatnagar et al., 2004). Maize and maize products (maize gluten meal or DDGS) are considered to be some of the most risky ingredients in terms of mycotoxin contamination.

The 2016 Nutriad Mycotoxin Survey included 46 maize samples collected across Poland. The 46 samples were collected either directly from the farms or from animal feed production sites. Sample providers were advised to follow the principles of good sampling (Richard, 2000).

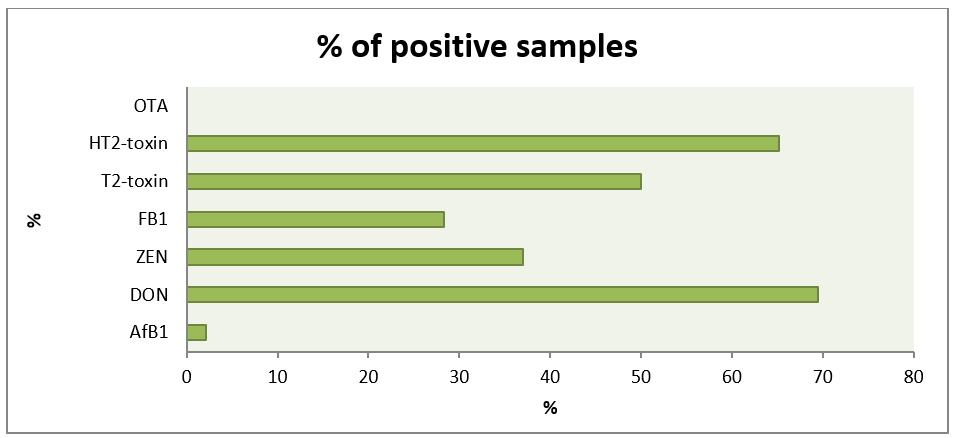

The analytical personnel and/or laboratory staff were not involved in sampling and, therefore, did not influence any part of this procedure. The survey provided an insight into the incidences of aflatoxin B1 (AfB1), zearalenone (ZEN), deoxynivalenol (DON), T-2 toxin, HT-2 toxin, fumonisin B1 (FB1) and OTA across all regions of Poland.

More than 320 analyses were conducted to test for the occurrence of the seven mycotoxins most frequently found in agricultural commodities that are intended for animal feed production. All seven mycotoxins were analyzed by liquid chromatography tandem mass spectrometry (LC MS/MS).

For the purpose of data analysis, non-detection levels were based on the limits of quantification (LOQ) of the test method for each mycotoxin: AfB1 < 0.5 μg/kg; ZEN < 10 μg/kg; DON < 75 μg/kg; FB1 < 125 μg/kg; OTA < 1 μg/kg; HT2-toxin< 4 μg/kg and T-2 toxin < 4 μg/kg.

The results from the Nutriad survey showed that almost 70 per cent of the maize samples were contaminated with DON and 65 per cent with HT2-toxin.

As expected only 2.2 per cent of the samples contained AfB1. Surprisingly almost 30 per cent of the samples were contaminated with FB1, a typical maize mycotoxin. Most of the recovered mycotoxins were in concentrations regarded as medium (>LOD but below EU recommendation levels). The highest concentration of DON and T-2 toxin found reached 1900 μg/kg and 327 μg/kg respectively.

Interestingly, 37 per cent of the samples contained zearalenone, a mycotoxin that affects reproductive performance in breeding animals. Its maximum concentration reached 1000 μg/kg, a significant level.

One sample was contaminated with AfB1, none of the samples were contaminated with ochratoxin A a known typical storage mycotoxin. One sample was positive for AfB1 but did not exceed the maximum EU permitted concentration of AfB1 in maize (20 μg/kg) (Commission Regulation (EU) No 574/2011).

The maize mycotoxin survey conducted by Nutriad in 2016 concludes that last year’s harvest of maize in Poland is of concerning quality in terms of mycotoxin contamination. Based on the results of this survey, it is the belief that this year’s maize crop should not be considered safe for inclusion into finished feed rations for all animal species.

Maize in animal feeds originates from many sources and vigilance is always advisable.

Maize harvested in 2015 across Europe has been shown to be contaminated with medium concentrations of mycotoxins. The last possible line of defense is the detoxification of mycotoxins in vivo.

The addition of proven mycotoxin deactivators to animal feeds is a very common method to prevent mycotoxicosis and is an effective strategy to keep the risk of mycotoxin contamination low under any and all conditions.

Nutriad delivers products and services to over 80 countries through a network of own sales offices and distributors. Supported by 4 application laboratories and 5 manufacturing facilities on 3 continents. Find out more at http://nutriad.com/