Nutriad: Addressing Current US Poultry Production Challenges

US - As of January 2017, medically important antimicrobials in medicated feed became veterinary feed directive (VFD) drugs.Strategies to face the new directive include proper management, hygiene, education and feeding programs. Implementing and maintaining a strong Bio-security program all times is a must. This also includes proper mortality disposal, as mishandled mortality from poultry barns creates “disease incubators”. Weighing mortality is always a good indicator for the flock weights and health. Total and proper cleaning of barns between production cycles reduces the need for any reactive or proactive remedies. Thus, a reduction of parasite/protozoal and respiratory challenges (load) and an improvement of gut health are noted.

Vaccine and vaccination programs are another important strategy to maintain a strong ABF program. Producers should be vigilant to all disease indicators through continuous proper monitoring of the flock and barns. Water systems should always be checked and cleaned to void incidence of chemicals, disinfectants, sanitizers and/or Biofilm. Producers should not use essential oils extensively, especially prior to any vaccination (at least for 2 days) to avoid negative effects that may contribute to “leaky gut”. Monitoring, measuring and managing the flock visually and keeping records on water, feed, mortality, etc. is always a good reference when needed to adjust, tweak or improve the production program.

While implementing the VFD regulation, the US poultry industry faces different challenges. Several of these challenges are driven by consumers as for example ABF production, veggie diets, no human antibiotics, GMO free, and free-range. Responding to these customer demands increases production costs, and right now those costs can be recovered. Impacts on production cost structure, and consequently product price, might affect consumer preference. Labor availability is another critical issue affecting the US poultry industry, following revision of immigration policies. Influenza is another major issue that needs to be always monitored. If HPAI hits the US, exports will be affected. From a farm management prospective, fixing biosecurity is cheaper than changing the environment to consistently handle all conditions. This includes continuous monitoring of everything to ensure that it is correct such as litter, feed, water, and ventilation.

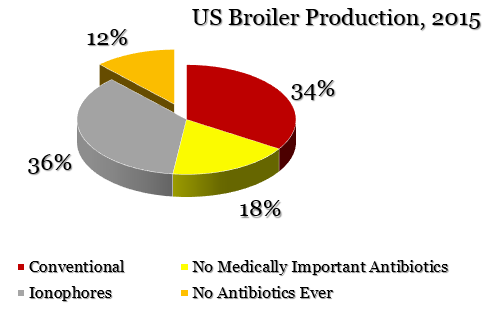

For example, no antibiotic ever broiler production represented about 12% of the US Broiler production in 2015 and this number was excepted to double in 2017. According to Watt Net, it now represents 33%.

The US Department of Agriculture reported that per capita poultry consumption has already increased in comparison to other meat categories starting in 2016. With the current VFD in place starting January 2017, this means that nutritionists have limited tools to utilize to achieve optimum production goals for responding to the higher consumption demand from this growing population.

Optimum gut health is a direct result of a well-balanced diet, microbiota and host. Feeding good quality ingredients, with proper feed additives that are not considered VFD drugs will result in a healthy gut microbiota with higher good bacteria than the bad bacteria “pathogens”. This will be reflected in better gut integrity with a solid cell wall barrier and improved bird heath.

Recently in North America, there has been a tremendous body of research investigating the ideal products or program to replace or reduce the use of antibiotics in livestock and poultry production. This is driven by the legislation to put VFD in place since this past January. Consumers will decide what they are willing to accept and pay for accordingly.

As there are many alternatives to AGPs, not all of them work well in the field. To evaluate these compounds, one should aim at understanding as much as possible about their safety, efficacy, and mode of action. If we are primarily looking to replace antibiotic growth promoters, we should first evaluate the effect on digestion and gut health.

Alternatives to AGPs “butyrate”

Butyrate is somewhat unique among its biological functions when compared with other short chain fatty acids (SCFA). The SCFA family constitute a group of molecules that contain from one to seven carbon atoms, which exist as straight or branched-chain compounds: predominant SCFAs are acetic, propionic and butyric acid. Because SCFA are weak acids with a pK of ≤4.8 and the pH of the gastrointestinal tract (GIT) is nearly neutral, 90-99% of the SCFA are present in the GIT as anions rather than free acids. Among the SCFA, butyric acid has received attention. Butyric acid is available in the salt form of Na, K, Mg or Ca. The advantage of salts over free acids is that they are generally odorless and easier to handle in the feed manufacturing process owing to their solid and less volatile form. For this article, the term ‘butyrate’ is used interchangeably for the acid, the salt and the anion forms.

Butyrate – Experimental results

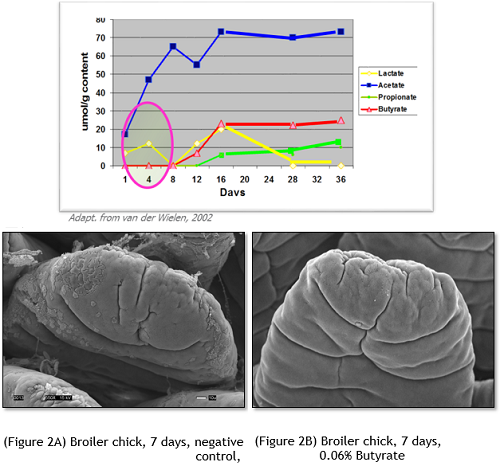

Dietary supplementation of butyrate has been shown to support enteric development and intestinal health of neonatal animals. At hatch, the chick’s small intestine has a very reduced absorption capacity due to the development villus height and crypt depth (Figure 1). Butyrate stimulates epithelial cell proliferation resulting in a larger absorptive surface, leading to improved feed utilization. Furthermore, butyrate supplementation during the starter diet supports villus length and thereby helps to maintain feed intake and better nutrient absorption.

Butyrate supplementation to starter diets positively supports gut morphology (Figure 2).

A broiler trial conducted at NCSU investigated early period (1 to 14d) butyrate supplementation on young broiler’s intestinal development and growth performance. Broilers were randomly assigned to 32 floor pens (30 birds each) and were provided feed and water ad libitum during the grower and finisher periods until 49 days. Dietary treatments in the starter feed were different levels of coated butyrate (0.0, 0.015, 0.03, and 0.06% butyrate) of 8 replicate pens per treatment. Body weight (BW) and feed intake (FI) was determined at weekly basis and feed/gain (FCR) calculated.

At 3, 8, and 14 days, 4 birds/treatment were sampled for gut histology evaluation. BW at 14 days increased linearly (p<0.01) as the level of butyrate increased (457 g vs. 470 g for 0 vs. 0.06% butyrate), while FCR for 1-14 days were non-significantly affected. Intestinal histomorgphology analysis correlated with early treatment effects on BW (Fig 2A and 2B). The positive starter feed treatment effects were observed throughout the experiment, with 0.015% butyrate resulting in a 3% and 2% improvement in 42 days (p<0.02) and 49 days (p<0.10), respectively. A linear improvement in 1-42 days FCR by up to 3% was also observed as the level of butyrate increased in the starter feeds. Dietary supplementation of coated butyrate in starter feeds showed to have a lasting positive effect on broiler growth performance.

Nutriad delivers products and services to over 80 countries through a network of sales offices and distributors. These are supported by four application laboratories and five manufacturing facilities on three continents. Find out more at www.nutriad.com