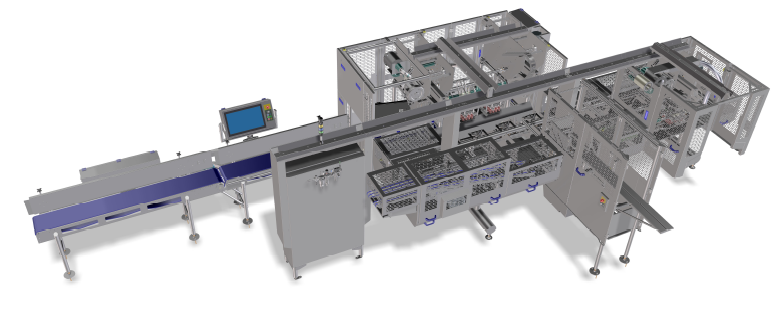

Moba launches new ML180 oader for gentler egg handling

Moba’s new ML180 loader is now available. The ML180 has been especially designed for the Omnia PX180 grading machine. The loader meets the requirements of today’s market such as gentle egg handling, hygienic design and good accessibility. The loader can load 180 cases per hour.With the introduction of the Omnia PX series, Moba has set a new standard in the industry with regard to three important goals for egg producers: efficiency, hygiene and food safety. With our customers’ need for a complete range of products in mind, Moba introduced the Omnia PX180 in 2018. The grader now comes with a brand new loader.

The ML180 can load 180 cases per hour on six-row-wide infeeds. It offers everything one would expect from a Moba loader, such as the gentle touch, high hygiene standards and the possibility to configure to ones needs.

© Moba

Gentle touch

The loader is placed at the beginning of the egg grader for grading purposes. Moving the eggs from the trays onto the rollers is a critical process. The eggs need to be treated gently to avoid cracks to ensure grade A eggs. Moba accomplishes the gentle touch through the ‘common speed loading’ principle. The loader synchronizes its speed with the infeed speed resulting in a gentle release of the eggs on the rollers. This drastically reduces the impact on the eggs.

High hygiene standards

The ML loader is constructed in such a way that makes it fully washable. The open construction makes it possible to clean every aspect of the machine quick and easy: only raising the covers to clean every part of your equipment is needed. The high standards of hygiene are met, but also cleaning time is reduced. This makes the operation as efficient as possible.

Configure to your needs

Another benefit of the ML180 loader is that the equipment can be configured to specific needs, which creates the ultimate fit into a packing station. The loader can be constructed in a left- and right-handed configuration, matching the grader layout. The orientation of the destacker or pre-loader can be positioned on the denester side of the machine, but also on the opposite side. The tray stack infeed conveyors can be oriented towards the left or right as well.

The ML180 loader is future-ready due to its ability to further automate a packing station. It is possible to equip the ML180 loader with Moba’s Easy Lift, for easy loading stacks of trays, or the MR50 De-Palletizer. The combination of layout choices and additional automation results in maximum flexibility in creating an efficient and future-proof loading solution.