Meyn releases unique self-adjustable wing cutter The Meyn Wing Cutter High Yield Pro

Variation of breeds and weights within and between flocks, combined with the growing average bird weight, can create additional challenges for poultry processors everywhere around the world. The pressure on poultry processors to be flexible with both variable input products (live birds of variable breeds and weight ranges) and output products has never been so apparent. Market margins are getting increasingly smaller throughout the poultry industry. Forcing poultry processors to increase their yield wherever they can and dealing with challenging circumstances.

The most carefree and flexible cut up solution

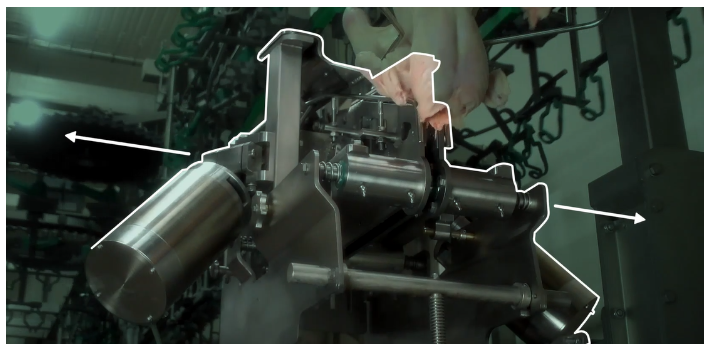

In close cooperation with various poultry processors, Meyn decided to redevelop the wing cutter to cope with variation of bird size and shape more conveniently. The development of the Meyn Wing Cutter High Yield Pro was a fact. This next generation of cutting module has the dual circular knives and their stainless-steel motors fitted within a spring coil suspension. Enabling the module to adjust to each bird individually, even whilst running at line speeds of an astonishing 7500 BPH (15,000 BPH when running a double line). For modern, high-speed poultry processor, smooth-running processing like that of the Meyn Wing Cutter High Yield Pro, makes all the difference.

As a matter of fact, even with a griller weight differentiation of up to 1,5 kg during process, the Meyn Wing Cutter High Yield Pro still reaches an astonishing accuracy in its anatomical cut. The highest accuracy of Cut Up within the market.

Additionally, the Meyn Wing Cutter High Yield Pro is adaptable to processing grillers from 1 kg up to an unrivaled 4,3 kg of griller weight with a minimum of adjustments required. With these heavy birds the operation runs smoothly without any blockage. As a result, flock and breed variations do not cause extra challenges at the processing line. An unseen achievement in any cut up module within in the poultry processing industry.

Cuts the tie with filet harvesting

Accuracy of wing cutting has a tremendous impact on the yield of breast deboning. Here the Meyn Wing Cutter High Yield Pro catches two birds with one stone: the high accuracy of anatomical cut, cuts exactly between the two joints. Leaving near to nun pieces of wing joint on the griller. Which, on its turn, results in an increased yield in fillet harvesting. When required, the cut can include a maximum amount of back meat while minimizing the amount of breast meat, but other combinations can be selected as well.

“With the new Meyn Wing Cutter High Yield Pro we don’t have to worry about the right set-ups no longer. We are extremely content with all that this Wing Cutter has to offer. Both considering the wings, as well as its effects on the processing results of the Rapid Plus M4.2 Breast Deboner.” –Poultry Processor within Europe.

With hundreds of Physic cut-up solutions sold worldwide, Meyn cut-up technology has proven to be very successful amongst poultry processors around the world. Today, Meyn is ready to launch the updated Wing cutter HY Pro and initiate sales. This upgraded automatic bird-size-adjusting wing cutter contributes to the need for carefree and flexible cut-up solutions with minimal down-time.