Big Dutchman manure management systems reduce carbon footprint

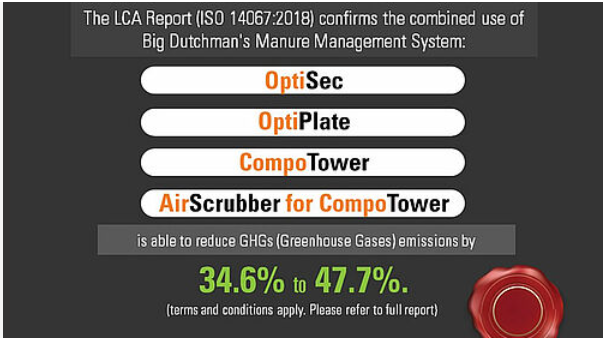

The Big Dutchman manure drying tunnels OptiSec and OptiPlate as well as the CompoTower fermenter help reduce the emission of greenhouse gases (GHGs) considerably. This was the result of a recent LCA study conducted by the industrial research and technology organisation SIRIM in Malaysia.

SIRIM assessed three different scenarios:

- scenario 1 representing the combined use of OptiSec for drying of fresh manure and CompoTower for composting,

- scenario 2 representing the combined use of OptiPlate for drying and CompoTower for compost production, and

- scenario 3 representing the sole use of CompoTower for fresh manure composting.

The results were then compared to a baseline scenario, i.e. the conventional manure management system of solid storage.

Results

The analysis showed that the combined used of OptiSec and CompoTower as represented in scenario 1, the combined use of OptiPlate and CompoTower in scenario 2 and the sole use of CompoTower in scenario 3 were able to produce a lower overall carbon emission of 567.2 kg CO2e, an average of 507.88 kg CO2e and 453.88 kg CO2e, respectively, as compared to the baseline scenario of 867.63 kg CO2e.

Relative to the baseline, this means that the quantified carbon emissions for scenarios 1, 2, and 3 were 34.6 %, an average of 41.5 % and 47.7 % lower, respectively. One of the primary enablers contributing to the emission reduction was the use of an air scrubber alongside CompoTower.

The analysis was based on the ‘cradle-to-grave’ life cycle assessment (LCA) approach, a methodology for evaluating the environmental performance of a commercial product in terms of carbon emissions, also known as carbon footprint (CFP).

OptiSec and OptiPlate

OptiSec and OptiPlate are manure drying tunnels developed for the optimal and efficient drying of fresh manure. The robust systems consist of several tiers equipped with manure belts or plates, respectively. The integration of an effective ventilation system ensures that the manure is dried very well.

Drying wet manure is a critical step before proceeding to manure composting to make sure that the process of composting is effective and successful.

CompoTower

CompoTower is a vertically enclosed, high-quality fermentation system. The components and properties of CompoTower enable an aerobic, high-temperature organic matter degradation, converting the manure into a high-quality compost, which is pathogen-free and nutrient-rich. The standalone CompoTower has a low space requirement of only 30 m2, thus giving the user great flexibility in farm layout design.

The enclosed CompoTower makes the control and treatment of odorous ammonia easy. Big Dutchman has developed the containerised air scrubber to solve the ammonia issue. One air scrubber unit can treat the exhaust air from two CompoTower units, with up to 99 % of ammonia separated.