Role of Feed Mill Laboratory Towards Improving Feed Quality

The goal of feed manufacturing is to produce feed that meets intended specifications in nutritional composition. writes Sunil Chauhan, a post graduate in chemistry working with Avitech Animal Health Pvt. Ltd as a lab technical officer.Today feed manufacturing is a very competitive activity and consistent feed quality is a key growth driver. Quality control and assurance have emerged as a critical feature in the business of feed manufacturing. A quality control system involves personnel being properly trained to ensure a high level of organisation, documentation and policing of various procedures and processes necessary to guarantee the basic quality of feed ingredients and feed.

Need for Laboratory

Laboratory analysis is a definitive aspect of a quality control. The analysis of raw materials can help the feed manufacturer in several ways, such as:

- Prediction of nutritive values of fed ingredients and feed

- Avoiding contaminants

- Detecting adulterants

A) Prediction of Nutritive Value of Feed Ingredients

Knowledge of feed ingredient composition is vital for the nutritionist in order to meet precisely the nutrient requirements of livestock. The nutrient values in any feed ingredient vary from season to season, source to source, batch to batch as also within a batch therefore feed ingredients need to be analysed carefully for their nutritive value before they are incorporated into the diet.

The graph in Fig.1 shows the variation in crude protein content of soybean meal used widely as a vegetable protein source. The crude protein percentage range from 37.60 per cent to 47.99 per cent in 49 samples analysed at Nutrisys.

Such variations unless otherwise accounted through laboratory, may lead to poor livestock performances or pinch the economy of feed production.

Source: Nutrisys analysis of Crude Protein in Soy meal in year 2005

B) Avoiding Contaminants

Substances that are inherently present in feed ingredients or acquired during processing, handling, storage etc and which may be harmful to livestock productivity are classified as contaminants. These, when present in more than prescribed levels are harmful to livestock productivity. Knowing the levels of these contaminants is important. (See Table 1)

Besides these there exist possibilities of bacterial contamination of feed ingredients, oxidation of oils and fats . The presence of mycotoxins in the feed due to mould growth is also a possibility. Pesticides /insecticides/ fungicides used by farmers are harmful for livestock when present at high levels. Usage of Thiram (Fungicide) in maize is common and this increases the incidence of tibial dyschondroplasia (TD) in poultry. A laboratory helps in detecting these contaminants and thereby protects feed quality.

C) Detecting Adulterants

Intentional contamination is termed as adulteration. Some unscrupulous agents adulterate feed ingredients in an effort to derive economic benefit. This adulterants seriously affect feed quality and thereby animal productivity and health (Table 2).

Laboratory and Feed Quality

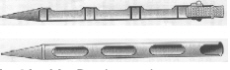

Sampling Equipment

| For Powder: Slot sampler. |

|

| For Grains: Open handed grain probes. |

|

| For Liquids: Bomb sampler |

Even a slight variation in quality of feed ingredients or feed affect animal performances. It is difficult to have a general assumption of the published values because a wide variability is observed in the nutrient content of raw materials. Whilst under formulating a ration will reduce animal performance and is an obvious quality deficiency, over formulation also deviates from quality since it results in losses of revenue.

The establishment of a feed mill laboratory can ensure feed quality by controlling the quality of feed ingredients and by assuring the quality of final feed. Every quality control program should include periodic laboratory analysis of ingredients and feed.

To achieve optimal animal performance well balanced diets that satisfy nutrient requirements of the animal is mandatory and for producing these diets accurate formulation is essential. The most accurate formulations result when laboratory analysis of ingredients is available.

How Can a Laboratory Improve Feed Quality?

Success of a quality control program hinges on collection of representative samples for laboratory analysis. Great care should be taken to ensure samples are representative of material so that lab results reflect the nutrient content of the ingredient or feed being sampled.

No of bags to be sampled √n +1.

For example: If total number of bags are 100, then number of bags to be considered for sampling is √1OO+1 = 11.

Procedure for collecting powder and grain samples

Source: Quality Assurance Manual ASA.

SiteA: Probe the grain approximately 0.5mt from the front and side.

SiteB: Probe approximately halfway between the front and center, 0.5mtfrom the side.

SiteC: Probe approximately three quarters the distance between the front and center of the truck, 0.5 mt from the side.

Site D: Probe grain in the center of the carrier.

Site E,F,G: Follow a similar pattern described above for the sites A,B,C for back half of carrier.

Collect approximately 1 Kg of the grain or powder sample in a tray and divide the sample into four parts as shown in Fig.3. Collect the sample diagonally opposite to each other. Quantity of representative sample must be approximately 500g.

Source: Quality Assurance Manual ASA.

Procedure for collecting liquid ingredients

Drums or barrels of liquid ingredient such as fat, oil and molasses can be sampled using a tube of glass or stainless steel, 1 to 1.5 cm in diameter and 0.5 to 1 meter long. Sample at least 10 % of the containers and collect a minimum of 500 ml. Liquid ingredients should be subjected to some stirring action (e.g. Rolling drums) prior to sampling to ensure ingredient distribution.

The following information should be provided with the sample to the laboratory.

- Contact details.

- Lot No./Batch No.

- Sample type

- Date sampled

- Sample location (Bag, truck, silo etc) Method of sampling

- Method of sampling

- Desired tests for sample

Testing of Feed Ingredients

At the feed mill, different feedstuffs need to be analyzed for different parameters depending on the vulnerability and the economic impact on the feed quality.

Table 3 enlists some of the test, which need to be carried out in different feed ingredients.

Proximate principles consist of Moisture, Crude Protein, Ether extract, Crude Fibre, Ash and Nitrogen free extract.

*Ether extract and moisture is the required test.

Critical Test for Some Feed Ingredients

- Maize-Thiram

Seeds are treated with pesticide Thiram. Presence of Thiram increases the incidence of tibial dyschondroplasia (TD) in poultry.

- Soy meal-Protein dispersibility index

Adequate processing of soya is necessary because if it is under processed, anti-nutrients will be present and if it is over processed protein degradation may occur. Urease activity, Protein solubility index and Protein dispersibility index are the three tests done in laboratory to understand soya processing.

Urease activity is a good indicator of under processing but not a good indicator of over processing. Protein solubility index is a good indicator of over processing but not of under processing.

Protein ddispersibilityindex is a good indicator of both under processing as well as over processing and also it relates to soya digestibility.

- MBM (Meat Cum Bone Meal)-Total Ash & Crude Protein

MBM is a dry rendered product derived from mammalian tissue, exclusive of hair, hoof, horn, hide trimming, manure and stomach contents.

Meat acts as a source of crude protein while bone act as a source of ash. So, in MBM crude protein is indirectly related to ash content. More the content of meat in meat cum bone meal more will be content of crude protein while increase in bone meal will increase the ash content.

- Fats & Oils-TBA Value

Fats and oils chemically are triglycerides (esters of glycerol and higher fatty acids). In general fats and oils are prone to rancidity, thereby losing its nutritional value.

Rancidity is of two types.- Hydrolytical rancidity

- Oxidative rancidity

In its initial stages oils undergo hydrolysis to produce free fatty acids while later on in presence of oxygen, peroxides are generated and oils become highly rancid. Further these peroxides are converted into aldehydes and ketones, thereby converting the oil/fat totally rancid. While in initial stage (hydrolytical rancidity) it is determined by free fatty acid test and the oxidative rancidity is determined by peroxide value. Although both of these test indicates rancidity, the conformation can be done by only TBA value method (production of aldehydes).

Testing of Micro-Nutrients

|

| HPLC |

Micro-nutrients are very critical in any feed manufacturing unit. Their analysis is also challenging.

Precise equipments like HPLC (High performance Liquid Chromatography), Flame photometer, UV spectrophotometer are required to analyze these nutrients.

It is feasible for large scale feed mill operators to have such equipments, otherwise it is recommended to analyze such Micro-nutrients from reputed labs or buy Micro-nutrients as a premix from reputed organizations.

Table 4 enlists the tests need to be done for micro-nutrients along with their periodicity.

Testing of Finished Feed

The performance of bird is totally dependent on the quality of finished feed. The following tests are important to decide the quality of feed. Every batch of feed must be analyzed for its proximate principals.

- Moisture

- Crude protein

- Ether extract

- Crude fiber

- Total ash

- Acid-insoluble ash

- Acid-soluble ash

- Salt

Further to this:

- Analysis of calcium, phosphorus and ME has to be carried out periodically

- All procedures should be carried out as per AOAC methods

- Every protein analysis should be carried out in triplicate and an average value should be taken

- Salt percentage should be considered by doing analysis for sodium and not for chloride.

Apart from these some other tests should be carried out to ensure a good quality feed, which are as follows:

- Coefficient of variation (C.V.)

The aim of mixing is to blend entire ingredients uniformly. C.V studies are carried out by analyzing the salt content for feed and manganese levels for premix. Table 5 summarizes the relationship between C.V and mixer performance.

For a premix C.V. should be below 5%.

Sieve Cabinets - Particle size

Birds perform their best on diets having uniform particle size. It influences:

- Selectivity of the bird in picking particles

- Amount of feed consumed

- Digestibility of the feed that enters in the stomach

It is evaluated by using US sieve no 8,10,14,28,48,100,150.

- Pellet durability index

The aim of pelleting is that birds should get each ingredient within a pellet.

If pellets break during the transport from feed mill to farms then the aim is not fulfilled.

Pellet durability index measures the damage that occurs during transport.

It is measured by Pellet durability index tester.

Conclusion

Compound feeds are composed as a blend of various raw materials and/or by-products. Whilst formulating feed, the feed manufacturer needs to find an optimum balance amongst different materials that will satisfy the requirements of specific animals in a specific physiological state. In order to achieve this, the manufacturer needs to keep an eye on the chemical composition and nutritional value of feedstuffs. Hence a laboratory at feed mill and right use of it can optimize both the quality and economics of feed manufacturing. A lab has a very key role to play right from purchasing of raw materials to despatch of finished feed. It requires a small investment relative to the enormous benefit of "customer satisfaction" and "enhanced productivity" through "Quality Feed".

March 2008