Hatchery Management: The Hatch Window

By Steven Tweed - The hatching of strong and viable chicks is a key factor in increased broiler performance. To increase the probability of strong birds, good hatchery management becomes critical. One management technique is to measure the 'hatch window'.The 'hatch window' is an investigation to check the number of chicks hatched after the eggs have been transferred from the setter to the hatcher. If the eggs are hatching too early, the chicks become susceptible to problems such as dehydration. Dehydration to chicks this early could lead to increased 7- and 14-day mortality and/or poor broiler performance. If the chicks are hatching too late, the result could be poor hatchability, chick quality problems, increased pipped eggs and live embryo unhatched eggs.

Method for Examining the Hatch Window

The procedure to investigate the hatch window is quite simple and should be included as a hatchery routine.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

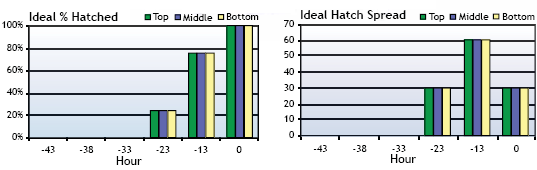

| 48 to 33 hours before pull Ideally, there should be no chicks hatching [below].  |

23 hours before pull 25% of the total pull should be hatched [below].  |

| 13 hours before pull 75% of the total pull should be hatched [below].  |

Day of pull 100% of the total pull should be hatched. The chicks should be dry and ready to process [below].  |

| The shell debris should be clean [right]. |  |

An example of advanced wing feather growth: this indicates that the chicks have hatched too early [below]. |

If the shell debris is soiled with meconium, it is another indication that the chicks have hatched early [below]. |

| This is the normal wing feather growth when the incubation cycle is correct [right]. |  |

Factors affecting early hatch include:

- Extended pre-heating period

- Setting eggs too early

- Incorrect setter and hatcher temperatures

- Hot-spots inside the setter and hatchers

- Incorrect ventilation

- Seasonal temperature changes

- Too many fertile eggs in the hatcher

Factors affecting late or delayed hatching include:

- Setting eggs too late

- Incorrect setter and hatcher temperatures

- Incorrect ventilation

- Seasonal temperature changes

- Eggs that have been stored for long periods

- Eggs that have been stored at too low a temperature

- Incorrect setting patterns in multi-stage machines

- Disease/fertility problems

Conclusions

The hatchery manager should be aware of the condition the chicks appear at pull.

The hatch window should be investigated periodically during the seasons. Not all hatcheries have a temperature-controlled environment. Where there is no control, setter and hatcher room temperatures may fluctuate during the year, affecting the time the chicks will hatch.

Setter/hatcher and ventilation calibration are essential elements of hatchery management.

Steven Tweed

Steven TweedSteven Tweed has served in the UK working as a hatchery expert since 1966. He brings with him extraordinary knowledge of hatchery operations as he has been responsible for the pedigree, great-grandparent and parent hatcheries for over 13 years.

Investigating the hatch window is an indication that procedures may need to be changed and regular servicing / maintenance of equipment is maintained.

The hatchery manager must have knowledge of 7-day customer/company mortality. It is essential information to understand what is happening with hatchery incubation.

August 2008