Sustainable Poultry: Production Overview - Part II

By Anne Fanatico, NCAT Agriculture Specialist - This is the second of three article's from the National Center for Appropriate Technology (NCAT) which provides information on raising poultry on pasture, including descriptions of production systems and facilities, as well as detailed nuts-and-bolts information.

Alternative Poultry Production Systems

Range poultry production systems, like other production systems, should provide fresh air, clean feed and water, and protection from predators; shelter from cold, rain, wind, and sun; and a source of heat when birds are young (brooding). Birds need to be able to grow, sleep, and lay eggs in comfort. In a good production system, birds are free from stress and disease. Alternative

systems also emphasize enabling the birds to behave in a natural way. Pasture-rearing is a cornerstone of this approach. In range systems, land should be well drained and well

covered with high-quality vegetation. Pasture rotation will reduce disease-causing pathogens,

avoid buildup of excessive manure, and prevent turf damage. However, if done improperly, production on range becomes a problem instead of an advantage.

In general, poultry are raised in three ways:

Confinement - you keep the birds indoors. Confinement is the production model used by the conventional industry; however, there are some applications to alternative poultry production. In the conventional industry, broilers are raised on litter-covered floors, and layers are kept in cages.

Free-roaming - Layers are not kept in cages but rather on the floor in buildings.

Outdoor: Contained - you contain (and protect) the foraging of the birds in some way - within a fence, pen, or netting. Containment allows you to have bird activity where you want it.

Yarding - Usually this is a stationary house with a fenced yard. However, the need to avoid buildups of manure, pathogens, and worms, and to provide fresh forage, has spurred grassroots range poultry producers across the U.S. to search for ways to rotate pasture and provide multiple yards.

Field pens - Floorless "pastured poultry" field pens or shelters are moved daily; "chicken tractor" pens are used in gardens for fertility and tilling.

Net-range or "day-range" (movable) - A small portable poultry house is used with movable net fencing.

Net-range (stationary) - Stationary houses are used with movable net fencing to rotate pasture.

Outdoor: Uncontained - you do not contain the foraging of the birds. Birds range freely during the day - usually in a pasture - and return to a portable house at night. The house is moved regularly to a fresh site.

Free-range (houses on runners or .skids;. houses on wheels or .eggmobiles.)

Colony . Several small roosting houses share a common nest house and feeding area.

Type - intensive vs. extensive

Fertility - heavy loads on a small piece of ground vs. light loads on a large piece of ground

Flexibility - getting started with a low investment and the ability to switch systems

Labor - labor-intensive manual vs. automated

Bird welfare - providing fresh forage and fresh air and permitting natural behaviors, while limiting exposure to the elements, predators, and pathogens

Site - or operation-specific needs - handling rough terrain, keeping eggs clean, etc.

The production systems are discussed in more detail below. Please note that the terms classifying these systems are not legally binding terms, but rather popular-use terms in the U.S., except for the term "free-range". However, the USDA definition for "free-range" livestock is vague: "free access to the out-of-doors for a significant portion of their lives". The lack of legal definitions in the U.S. causes marketing problems and consumer confusion.

Confined Production

Confined production is the system used by the conventional poultry industry. It can be a stand-alone operation on a small amount of land and permits a high level of automation that reduces labor. Manure must be managed intensively.

In the industry, broilers are raised on littercovered floors at a density of 0.7 square feet per bird. Layers are raised in cages (four to a cage) at a density of 64 square inches per bird (7). Cages may be modified to provide more space. "Freeroaming" refers to layers that are kept on the floor of the house, not in cages. Eggs from alternative confinement models are sometimes marketed as "barn eggs" or "nest eggs"; however, "free-roaming" broilers would not be any different from

conventional broilers.

In Europe, additional comforts, such as roosts, are offered to layers. Some of these modifications

may be of interest to range poultry producers in the northern U.S., where flocks may have to be kept indoors a lot in winter. Percheries and aviaries use perches and platforms to increase

vertical space in the house, to allow birds to jump around (8). Slatted floors, used by the

conventional industry for broiler breeder housing, are a way to increase stocking density; birds

roost on the slats at night and droppings accumulate in a pit.

An interesting floor-raised layer production system was developed by Virginia poultry pioneer

Joel Salatin (9) (also known for his "pastured poultry" production system). His "raken house" system keeps chickens with rabbits. The rabbits are kept in hanging wire cages and the chickens are floorraised. The chickens scratch through the rabbit droppings, aerating the litter. Salatin believes indoor flocks should consist of no more than 300 layers. He also believes that stocking density should be no more than 1 hen per 3 square feet. Otherwise, the manure load exceeds the birds. ability to incorporate it into the litter by scratching.

In the past, sunporches - elevated runways with wire platforms - were commonly used in poultry production to provide access to sunlight and fresh air. Wire or slatted floors permitted manure to pass through. Nowadays litter is used to dilute manure in confinement production. Sunporches were used to raise birds to maturity, but they also helped poultry to make the transition between confined brooding and outdoor production systems.

Outdoor Poultry Porduction: Contained

Yarding, even on a small scale, can result in dirt yards. |

Although this system can be run with minimal labor (especially if feed and water are somewhat automated), disadvantages include manure and pathogen buildup and turf damage, particularly around the house. The result is "fowl sick" land. In fact, range poultry producer Robert Plamondon in Oregon (10) calls this system inferior to the confinement system because of the disease potential. Mud from bare lots dirties eggs, greatly increasing egg cleaning costs, and yards with heavy clay will become hard and packed from continuous use. According to Plamondon, this system may only work in very dry climates, such as parts of the western U.S., where biological activity is low and pathogens are kept at bay. Older birds, such as layers, are less susceptible than young pullets or broilers to health problems in yards.

A similar system is the "farmstead" production model, which permits poultry to roam a farmstead at will during the day and shuts them in a coop at night. There is no fence, and the birds continuously have access to the same piece of ground. While this may work at a low density and be appropriate for hobby production, it is generally not a commercial production system in the U.S. Disadvantages include loss to predators and droppings in undesired places such as your porch. According to Plamondon, you can get away with anything at low densities (i.e., a 25-50 hen flock) but at higher levels, you need to use a commercial production system.

One way to help reduce the "fowl sick" land problems of yarding is to rest the ground by "double yarding" - dividing the yard in two with a fence and rotating the flock. The British book Free-Range Poultry (11) by Katie Thear describes a quadruple yarding system with four rotating yards accessible by four .popholes. (bird doors) from the house. Unfortunately, Thear has yet to see any yarding system that can solve the problems on a large scale.

As mentioned earlier, excessive fertility is prevented when litter is cleaned out of a house and spread on other land, but this is labor-intensive. Resting the ground for part of the year is helpful in reducing manure load and pathogen buildup. Older systems used cultivation of crops as part of yarding to use up the nutrients and keep the soil loose. Although many pathogens and parasites will die after their hosts (poultry) are removed, some are able to survive for a long period of time and re-infect birds when they are returned to the land. Moving a semi-fixed house after a few years to a new site or fallowing the site would solve the buildup problem.

Yards may simply be "scratching areas". In this case, the focus is on providing not vegetation for foraging but just a place for outdoor access. Amendments such as straw, mulch, sand, or even concrete may be preferable to a dirt lot. They may help reduce mud, and could be removed or cleaned. In the U.K., scratching areas may be open yards, yards partially covered with an overhang, or enclosed verandas.

Straw-yard scratching areas may be a way to address problems in yarding. Plamondon has reported on a system used by a British poultryman in the 1940s. A relatively small yard was completely covered with a thick layer of straw. Additional straw was added weekly. In winter, straw was placed on top of snow! The yard was sheltered to prevent the wind from blowing the straw away. Once a year, the entire layer of straw was removed by bulldozer. Plamondon believes a straw yard has potential as a good hub for pasture-based systems in the U.S.

In Europe, yarding is common, but stocking density recommendations differ in the various certification programs.

- The European Union requirements for "freerange" poultry limit stock density to 1,000 hens per hectare (400 per acre).

- A U.K. organic program called the Soil Association requires fewer birds: no more than 625 hens per hectare (250 per acre).

Birds in the French Label Rouge certification program are generally raised in .semi-intensive. or large-scale yarding systems. |

In France, 30% of poultry is produced on range under the Label Rouge certification program. Generally, yarding is used, sometimes unfenced. Under this program, 500 birds per hectare (200 per acre) are permitted, although some participants voluntarily increase the space.

When yarding is done on a large scale in Europe, it is called "semi-intensive". The European

Union definition for "semi-intensive" is 4,000 birds per hectare (1,600 birds per acre). This type

of production is done by some large range poultry companies in the U.S. Even the final rule of

the USDA National Organic Program permits this type of industrial production system.

Field Pen Production System - "Pasteurised Poultry"

Field pens are inexpensive shelters that are set in a pasture, garden, or lawn and moved daily

to provide multiple yards. This is a favorite production system for beginners, because expenses

are minimal and many of the management details have been worked out, giving producers a good rate of success. However, moving the pens daily is very labor-intensive.

The popular "Salatin" pen. |

The pens, which weigh about 200 lbs., are moved manually by putting a custom dolly on one end and lifting by a handle on the other. Birds learn to walk along with the pen as it is dragged across the field, but occasionally a bird will escape or be crushed. Some producers find they need to move the pen twice a day when the birds get bigger, so that the grass is not "burned" and the birds are not sitting on manure. No litter is used.

Since the field pen is only a shelter, this system is seasonal; birds are usually raised only in warm weather. Pens may need to be propped up in hot weather to allow ventilation. On rainy days, producers use hay to help keep chickens dry under the covered section of the pen. Low spots in the pasture should be avoided, since puddles may form during rain. Roosts can help layers stay out of puddles and manure. The daily moves control coccidiosis, a parasitic disease that occurs when birds stay in contact with manure.

The confined space inside the pens makes bird welfare a concern; however, although the birds are not free to roam, they still have the important advantages of fresh forage and fresh air. Pens may not be suitable for turkeys because of their large wing spans.

A field pen generally provides good predator control, but some predators (namely raccoons) can grab chickens through the wire. If there are low spots in the pasture, holes between the bottom of the pen and the ground need to be stopped up with scraps of wood or other materials. Some producers surround the pens with electric net fencing.

Size, design, and construction material can be modified in many ways to make the pen lighter to move, to adapt it to hot climates, or to address other needs. PVC pipe and rebar have been used in place of wood to lighten the structure. However, in areas with strong winds, light pens need to be staked down. Some producers peak the roof to allow more heat to escape, to keep rainwater from pooling, and to keep goats off! Skids or wheels can be used instead of a dolly to move the pen. The field pen can also be adapted for egg production by adding nestboxes (hanging or on skids). See ATTRA.s Range Poultry Housing for pen designs and construction details.

Pollo Real in Socorro, New Mexico, is the largest field-pen operation in the U.S., producing 50,000 broilers per year. In Europe, there are some pretty fancy - and expensive - pens. Some have attached housing; these European "ark" houses are available through U.S. distributors, but there are also some similar U.S.-designed and -built pens. The Henspa (13) is one such American product. Sold for about $1,000, this unit for 12 layers can be moved on lawns or pasture; it.s designed for busy people and features an automatic feeder and waterer. Attractive, elaborate designs like this are described in ATTRA's Range Poultry Housing; they are used in the same way as the field pen. The "Chicken Tractor", popularized by Andy Lee (14), is another well-known poultry pen, used in a system to provide fertilizer for vegetable production. It is discussed below under the heading Permaculture Production Systems.

Net-Range or "Day-Range" Production System (Moveable)

Net-range uses portable net fencing around a house to make multiple yards. Houses are also moved regularly to fresh sites. This low-cost, flexible system facilitates larger-scale production since moves do not need to be daily. Also commonly called "day-range," netrange production is usually one component of a diversified farm, done on pastures that are also used for cattle or other ruminants - an extensive system.

Electric fencing technology has allowed the development of net-range. Electric net fencing comes in rolls of 150 to 165 feet. Some brands have step-in posts and are easy to move. "Fence the flock - not the field" is a motto of this sophisticated system. It allows you to direct your birds' activity right where you want it. The housing is usually enclosed; it offers improved protection for the birds compared to shelters and a year-round production option.

Net-range has not been fine-tuned; it is still a "work-in-progress," benefiting from continual innovation. The descriptions below are snapshots of the current state of net-range production.

Andy Lee (14) in Virginia, who coined the term and has pioneered the development of "day-range" systems, uses portable housing on skids or runners. His house has popholes at the ends. He loops the electric netting around one end of the house to make a paddock and opens the pophole so the birds can come out. The netting encloses an area roughly 40' x 40' (1,600 square feet of pasture) in which Lee raises 200 broilers or 100 turkeys (he also raises layers with this system). After a week, he moves the netting to the other end of the house. Weekly rotation gives the paddocks a rest. This is similar to the double-yarding practice described earlier, but it is on fresh sites, since the house is moved after each grow-out period. Lee says that 1,000 broilers per acre is fine. The pasture grass under the house may need to be re-seeded. David Schaffer (15) in Kansas uses a floorless house with litter and found it can take two to three years for pasture to recover.

Having used many different "mini-barn" designs for housing, Lee prefers a hoophouse with a litter-covered plywood floor. The house is on pressure-treated skids and is moved by tractor, pickup, or draft animal. Lee recommends at least a square foot of floor space for each broiler in the house.

A floorless hoophouse with roosts; litter on the ground. |

http://www.groups.yahoo.com.

As producers work on fine-tuning "dayrange" systems, some recommend that water be placed not only outside but also inside the house. In heat, cold, or rain, some breeds of bird may be reluctant to leave the house. Perimeter fencing around the entire pasture may or may not be used in addition to the netting enclosure. Since many producers graze poultry in ruminant pastures, perimeter fences are often already in place. Some of the factors producers consider in housing are listed below.

"Floor vs. no floor". This is an important consideration in range poultry housing design. A floor is sometimes a structural necessity to keep hoops in place or keep the house from pulling apart when moved. Also, a floor may be required in cold regions to keep the birds off the ground and can help producers extend their season. Litter is used for insulation on floors, but it is labor-intensive to handle and clean out. A bird-cagetype floor that could be removed would be an easy-to-clean option. Other options include using a slatted floor or mesh floor with no litter or insulation. Litter is sometimes put directly on the ground in floorless houses, but it can be soaked by heavy rains. The litter can be left behind when the house is moved. An additional option for a floorless house is to use roosts for layers with no litter; however, the manure pack may need to be scraped after moving the house.

Number of popholes. The number of paddock subdivisions can be increased by adding more popholes on the sides of the house that open directly to them. Broad popholes reduce wear and tear on turf at the entryway. Some houses have panels at the bottom that open like a clamshell. Some have continuous openings all the way around at the bottom, encircled by netting, making a central hub.

Closing doors vs. not closing. Opening and closing the doors of a house in the morning and at night is time-consuming. With netrange, you may be able to forego the task, since the birds are protected from predators by electric netting day and night. However, if they bed down outside, they may get rained on or preyed upon by owls. Layers return to the house on their own at night, but may need some initial training. Producers keep them locked in for a few days or shoo them inside in the evening for the first week. Broilers and turkeys are more of a challenge. Depending on the breed, they may not seek shelter as readily. Having broad popholes in the house can help. Lee (14) makes sure a feed trough is in the shelter in the late afternoon to encourage broilers to return to the house. David Schaffer (15) had owls enter an open door even after the birds returned to the house. Therefore, he uses a flap door on his house. Birds can come and go, but the flap deters owls.

Electric vs. non-electric net fencing. Since most predators are nocturnal, some producers turn off the electricity for their net fencing at night if the birds are shut in and the house is predator-proof. Producer Tim Shell in Virginia is leading the way in exploring non-electric netting. It should be electrified if you have daytime predators (such as stray dogs) that will not respect the fencing.

Net-range Modifications

The house can be completely encircled by netting, forming one large paddock. Joel Salatin (9) encircles a quarter-acre around the house with netting and puts 1,000 layers in it . he calls this

system the "feathernet". He moves the house and netting to a new site frequently (every three

days), making a figure-eight with two 450-foot circles of netting (using three rolls each), so he can move the housing into a new circle without letting birds escape. It takes Salatin one hour to move the system, including two skid hoophouses (20. x 20.) hooked together, along with a feed sled in a "train". The unit requires five acres of pasture and seven hours of work per week. The houses are floorless and no litter is used for bedding. He uses the system only for his layers and does not shut birds in the house at night; the birds return on their own.

There are other variations on net-ranging. Some producers use a combination of field pens and net-range, opening up field pens within netting enclosures; the birds range in the entire enclosure during the day. The pens may be moved several times before moving the netting enclosure, but they do not have to be moved daily, since the birds only sleep in them. Aaron Silverman in Oregon groups three pens together in a netting enclosure and moves the enclosure every three to five days.

Net-Range or "Day-Range" Production System (Stationary)

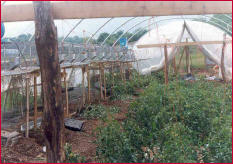

In addition to portable houses, net fencing is also used with stationary houses to make paddocks.

Since houses are fixed or semi-fixed, it is possible to incorporate more labor-saving automations

of feed and water delivery. Since it is an intensive production system, operations can be stand-alone and done on a small amount of land, but careful manure management is required.

Luke Elliott in Arkansas has used stationary 12' x 21' hoophouses with doors on both ends,

making paddocks with electric netting as needed to maintain pasture. He keeps 210 birds in each

hoophouse. The turf right around the door of the house gets worn down; Elliot believes that

multiple exits are an important modification to reduce turf damage.

Tim Shell (17) in Virginia is a pioneer of stationary and semi-stationary housing. He makes multiple paddocks in a wagon-wheel design with netting. He developed a "stationary netting model" for his broiler breeders; however, he recommends this system for layers and broilers as

well.

For layers he recommends a house with eight popholes to access eight separate paddocks. He

makes one quarter-acre paddock at a time, radiating out from the house in the shape of a pie

slice, using two rolls of electric netting per paddock. Birds are moved to a fresh paddock every

seven days. He uses the same ground several times a year but believes that the seven-week rest period helps prevent disease and parasite problems. He encourages foraging by gradually moving

the range feeder to the end of the paddock away from the house. He uses a total of 2 acres

for 400 heavy layers and recommends irrigation (in Virginia). For broiler production, birds

should be kept for a relatively long time on the first paddock, when they are still small, and for

a shorter time on the last paddock when they have grown. Although this is an intensive production

system that can be used without ruminants, Shell grazes sheep in the poultry paddocks.

His housing is a 15. x 40. hoophouse providing 1.5 square feet per hen, with no floor but with

litter on the ground. Roosts are provided. The hoophouse is stationary but is built to move to a

new location if needed. He is also trying out a kit to build a small predator-proof hoophouse (8.

x 16.); he will place 100 birds in it. The small house has six popholes accessing six yards.

Another design option Shell recommends is a central straw yard around an open-bottomed house encircled with netting. This can be used instead of multiple popholes in the house, because

birds can come and go from any part of the house. An .instant gate. to a paddock can be made by propping up the inner circle of netting.

Shell sells a "Stationary Netting Model Manual". He is also working on:

- Several permanent pads to which the hoop cover can be dragged and mounted. This would create multiple houses with less expense; the houses could be used in rotation.

- Use of old poultry houses - there are many in the South. Using net fencing with these stationary houses could provide good access to range.

- A conveyor system to reduce labor in handling eggs.

Outdoor Poultry Production: Uncontained

In uncontained outdoor production, the foraging of the flock is not contained by a fence, pen, or netting - birds roam at will. "Freerange" usually refers to operations using portable housing that is regularly moved through a pasture. Birds have total freedom during the day, but the producer has to be faithful about shutting them up at night for protection from predators and the elements. This is usually a mixedhusbandry system; since producers typically graze poultry on ruminant pasture, there is usually a perimeter fence in place for the cattle or other livestock. While these perimeter fences help deter predators such as stray dogs, they are usually not meant to contain poultry. Birds are more subject to predation than in other systems. Since foraging is not managed by net fencing, birds may concentrate in an area for an extended period, damaging pasture.

Free Range Production System

Salatin's eggmobile is moved every 3 to 4 days |

If a layer house has wheels, it is often called an "eggmobile" or a "layaway;" these are generally moved often. Joel Salatin (9) has been instrumental in popularizing an eggmobile system in which a layer house is mounted on a trailer hitch and moved through pasture every three to four days, following grazing cattle. He finds that significant acreage (a minimum of 50 acres) is needed in order to move the birds far enough each time that they do not return to the previous spot or identify a favorite spot such as a garden. Wheeled housing can be difficult to park on hilly land. Foraging for insects and plants, the layers will range up to 200 yards from the eggmobile. They usually return but sometimes get lost. Salatin says the eggmobile can be returned to a plot of land after just one month.

Salatin first developed a 12. x 20. house for 100 to 200 layers. He later hitched a second house to the eggmobile and now houses up to 400 layers. The house must not be made so big that it is unwieldy to move. Since the birds only stay inside the eggmobile at night, Salatin allots only one square foot per bird. For use in the winter or during long periods of inclement weather, more area may be needed since birds will remain indoors. He provides feed inside the house.

In cold weather, bales of hay are added for bedding. According to Salatin, the frequent moves deter predators. When the layers are newly placed in the eggmobile, he encloses them with poultry netting around the bottom of the structure for the first night, so that they learn to go in.

Old mobile-home trailer frames have been used for eggmobiles. Wheeled houses for broilers are not as common. Please see ATTRA's Range Poultry Housing for a discussion of eggmobile design.

Skids

Skid housing is used in the "Modern American Free-Range" system for broilers, popularized by Ohio farmer Herman Beck-Chenoweth in his book and video Free-Range Poultry Production and Marketing (18). He developed the system for broilers but it also serves for layers. Portable houses on runners (skids) are moved every few weeks to new locations in the pasture. Broilers range freely during the day, foraging about 100 feet away from the skids. Beck-Chenoweth finds that the birds return to the house on their own at night. It is necessary to open and close the house in the morning and evening. He stresses the importance of a strong perimeter fence to reduce predator pressure from stray dogs; predation at night is generally not a problem if the chicken wire is tightly attached to the skid. He doesn't recommend more than 400 broilers or 100 turkeys per acre.

Beck-Chenoweth.s 8' x 18' wooden skid houses are enclosed with chicken wire and have gabled tarp-covered roofs and litter-covered wood floors. He keeps about 300 birds in them. This is a high density, but since he harvests continously some birds are small. Beck-Chenoweth's system is described on his website http://www.free-rangepoultry.com.

Skids used for turkey production may be little more than roosts. Heritage turkey breeds are hardy and do not require a lot of shelter when mature.

The British book Free-range Poultry (11) shows a number of different skid housing designs on pasture. Some are surrounded by hay since they are not moved frequently. The attractive housing used in the U.K. reflects "planning permission" requirements to keep poultry housing looking decent, even in rural areas, to benefit tourism.

A number of modifications can be made to the free-range system:

- Some producers use a system combining field pens with free-range. They open up their field pens and let birds roam during the day, returning them to the pen at night.

- Bob Tochor in Saskatchewan, Canada, uses a portable hoophouse within a very large electric netting enclosure - an entire acre. His 15. x 15. hoophouse contains 250 birds. Only one house is placed per acre.

- Jim Hawthorne also fences a large area. To deal with heavy predator pressure, he uses netting and electric wire to make a strong, permanent perimeter fence. He moves two houses around in the enclosure and believes that 600 birds per acre is viable.

- Herding, a free-range method, was used in the past with turkeys. Turkey foraging was managed by a herder.

- "Wire-ranging" is a type of free-range. Electric wire is used, not to confine or manage the birds, but rather to deter predators.

Colony Production System

The colony system uses multiple small roosting houses scattered on pasture. It is based on a mixed poultry-livestock system that was popular before 1900 in the California poultry industry centered near Petaluma. The houses have nothing inside but roosts. "Colonies" of roosting houses share a feed area and a nesting house. A nesting house has nothing but nest boxes. The system has been promoted for layers by Robert Plamondon (10) in western Oregon. He moves his houses every few weeks to a new spot 20 to 100 feet away. A perimeter fence reduces predation.

The colony system lends itself to egg production; according to Plamondon, it reduces the labor

involved in gathering eggs from houses on range. Eggs are concentrated in special nest houses; the producer collects the eggs onto flats for pick-up by truck or ATV (or, in the past, horse). Plamondon says it is an indication that you need a nest house when you have more eggs than you can carry. Nest houses have litter on the floor to clean hens. feet before laying.

Again, the roosting houses contain only roosts inside. Plamondon's houses are floorless and no litter is used. They are on skids. When he moves the house, there is a 2- to 4-inch layer of manure left, which he scrapes with his tractor. The houses should be kept 100 yards away from barns, garages, and other places where you don't want birds to roost.

Plamondon recommends the colony system for mild climates on the Pacific coast and throughout most of the South. Roosting, nesting, and feeding should be under a single roof during the winter in areas with prolonged periods of freezing.

Plamondon's unique open-fronted housing design frees him from having to close his houses up at night. The front wall of the small 8' x 8' house is only 20 inches high. Chickens hop up to the top of the wall and then into the house. Climbing predators are deterred by an electric fence wire strung on insulators along the front wall. However, some predator losses occur at dawn when birds leave the house too early, or at dusk.

Plamondon encourages foraging by keeping the feeder and waterers outside the house; the feed area is 50 to 150 feet from the house. He also tosses scratch grain on the ground away from the feeders.

He keeps 50 hens in each small house, and his colonies consist of 200 hens each. Plamondon has details on his colony system and house construction, as well as other poultry resources, on his website http://www.plamondon.com.

Permaculture Production Systems

"Permaculture" integrates natural systems with the production of food, shelter, fiber, and other human needs. Permaculture poultry production systems are usually less commercial than other systems and are specialized to focus on services poultry can provide, such as fertilization, tillage, and insect and weed control. Since the systems are so varied, they are not classified

as contained or uncontained in this publication.

Chicken Tractor

The "chicken tractor" system was popularized by Andy Lee and Patricia Foreman of Buena Vista, Virginia, in their book The Chicken Tractor (19). The system integrates poultry and vegetable

production, using a small floorless pen enclosed with chicken wire and a covered top. The

pen is moved daily on fallow beds. You may need twice the garden space to use this system,

but this allows the land to be "treated" every other year. Garden yields are increased by the

added fertility. The chickens also weed and till the beds and help control insects. Garden wastes

are useful feed supplements.

In addition to rotating the pen daily to a fresh spot, Lee suggests other ways to use the chicken

tractor in a garden, such as keeping the pen in one spot and adding fresh straw bedding daily

to create a raised garden bed. (However, according to ATTRA Soil Specialist Barbara Bellows,

unless a lot of manure is added or over a year is provided for the straw to decompose, the straw

will immobilize nitrogen and other soil nutrients.) Moving the pen after less than one month

will put a sheet-mulch on top of the beds to kill grass and weeds and add fertility.

Lee uses a 4' x 10' pen that holds 20 broilers or 10 layers. Some producers add a small portable

house to the chicken tractor to provide more protection from the weather and to hold nestboxes. Small runs have also been attached.

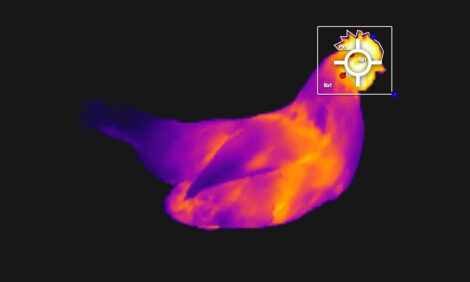

The inside of Salatin's overwintering hoophouse planted with early vegetables |

In another permaculture example, Joel Salatin (9) uses a hoophouse for overwintering layers and integrates it with other farm operations. His son's pastured rabbits are also moved into the hoophouse during the winter and kept in wire cages. Below the cages, a wire covering over the rabbit droppings keeps the chickens out of the manure bed, which is used to produce worms. However, the chickens are allowed to roost on the wire and thus add fertilizer. Pigs are also kept inside in small pens. In the spring, after the animals are removed, the hoophouse is used for vegetable production - vegetables are planted in the bedding to get an early start.

There are many other permaculture systems for range chicken production. Art Biggert and Suzy Cook in Washington place a portable house in their market garden and enclose a bed with netting. Their layers forage on winter cover crops and post-harvest crop residues. The house and fencing are moved every two to three weeks. Other permaculture systems include building hoop tunnels in the garden; having permanent wire runs and moving a portable shelter to the runs in succession; and attaching runs to housing. Permaculture systems often focus on selfforage systems; practitioners claim poultry will eat many types of shrubs and plants. See Bill Mollison's book Permaculture: A Designer's Manual (20) or Alanna Moore's Backyard Poultry - Naturally (21) for more poultry permaculture ideas. ATTRA also has information on greenhouse systems that incorporate poultry and rabbits and make use of their body-heat production.

Choosing a Production System

All systems offer advantages and disadvantages. Tim Shell recommends "thinking for yourself" instead of copying someone else's recipe. Each type of system can be effective, depending on the producer's management ability and level of commitment.

Your motivations will influence the size and type of production system you choose. Do you plan on range poultry being a farm centerpiece or a part-time source of supplemental income? Do you plan on year-round production or seasonal? The following are important considerations:

Intensive vs. extensive. Do you already own pasture and raise ruminants or have access to pasture? If so, you can probably consider an extensive system. If not, it may not be profitable to buy land just for the purpose of extensively raising poultry. Therefore, you may need to choose an intensive system.

Fertility implications. How do you plan to manage the fertility brought in by poultry? Do you want a light coat of manure spread over a large area or heavier manure on a smaller area? Can you remove excess nutrients by rotating poultry land with crop production, grazing with ruminants, or making hay? Do you want fertility for your pasture? Or composted litter for your market garden or crops? Composted litter can be a valuable by-product for sale, but does it pay you enough to justify the labor involved in manure handling?

Making paddocks with net fencing allows for good fertility management - you have control of the birds' foraging and the ability to concentrate their manure deposition and other activity as desired. A field pen also concentrates fertility where you want it, but a pen filled with large broilers can leave a mat of manure.Flexibility. Many producers start with the most inexpensive system - a field pen - and try out one batch to see whether they like raising and processing poultry and whether they can build a market. Pens can be built from scrap materials on-farm and can be moved by hand. No tractor, draft horse, or pickup is needed. No fencing is required; a pen can be moved to any convenient place. Pens are a flexible option for those who do not have cattle pastures. While many producers eventually switch to a different production system as they grow, there are some operators who have a fleet of pens.

Production systems using field pens, temporary fencing, or no fencing at all allow you to put your operation in any pasture, even leased, without making expensive improvements. If there is no perimeter fencing, you might want to consider a net-range system.Labor and management. While producers discover many labor-saving solutions in any production system, there are important inherent differences among the systems. For example, with field pens, there is no need to open and close doors. With an uncontained outdoor system such as free-range, you need to be faithful about opening and closing doors (or devise an automatic closer). According to Robert Plamondon (10), there used to be full-time workers in California's Petaluma poultry industry employed to open and close doors in the morning and evening. Net-range systems may or may not involve door-closing.

Moving houses takes time. The daily moves for field pens are particularly labor-intensive, but cleaning litter out of a house also takes time. Back injury from dragging heavy field pens by hand is a concern for some. Daily moves require a lot of discipline.

Opportunities for automation of feed and water delivery are greater with stationary or semi-stationary housing - important in reducing labor. Users of field pens are noted for hauling five-gallon buckets of water and feed to each pen. Pens have to be served as individuals units, sometimes twice a day; pens may take twice as long to service as other systems. Replacing the use of five-gallon water buckets with piped water reduces labor with pens. Ease of access is also an issue. It can be hard to reach birds in parts of the field pen, depending on design; larger houses allow you to stand up.

Management is a key consideration, especially when adopting a new system. It takes a lot of time to work out the production details, such as how often to move a house or how often to move net fencing. An advantage of the field pen system is that many bugs have already been worked out.

Although reducing labor is important, it is also important to take time for a close-up look at your flock every day, to monitor their health and catch any problems.Bird welfare. Some consider the field pen inhumane because it exposes birds to the elements. Pens do not provide the substantial protection offered by enclosed housing; birds are affected by cold, heat, wind, and rain. The confining quarters can lead to pecking problems, because the birds lower in the pecking order cannot run away. Some egg-eating occurs because the birds do not have a lot to do. Birds may end up spending time in manure when they are larger, and breast blisters can develop. On the other hand, the Cornish cross birds typically used for meat production are not active anyway. They were bred for confinement systems that encourage inactivity, since activity burns calories that could be used for growth. If more-active breeds are used, less-confined systems may be preferred for welfare reasons.

Site-specific and Operational Needs

Terrain. Rough terrain can make towing houses more difficult and pulling pens by hand impossible. In arid climates, hard ground may be a problem for inserting posts for net fencing. A free-range system like the eggmobile requires extensive pastures to keep birds from returning to the same place.

Predators. Heavy predator pressure increases the risk of losses. The field pen usually protects against both overhead and ground, daytime and nocturnal predators. Some producers attempt another system but switch back to pens in the face of hawk problems. In a free-range system like the eggmobile, layers may wander off and get lost.

Weather. Preparing for weather extremes is important. Enclosed housing ensures shelter from the elements, and your workload stays the same when bad weather occurs since you are already prepared. In windy areas, it is easier to weigh down one house instead of several individual pens to prevent them from blowing away. Field pens, shelters, and other non-enclosed housing must usually be shut down for winter, especially in areas with cold winters.

Operation-specific. There are many specific considerations and tradeoffs that depend on your operation. For example, if you are producing eggs on range, it is important to use a production system that keeps the eggs from getting dirty. Cattle may interfere with poultry housing if there is no netting or fence to keep them away. For processing, it may be easier to catch poultry from a house than from a pen; David Schaffer (15) funnels chickens right from his house into a stock trailer. The choice of a production system is related to the type of chore cycle you want.light work every day or heavy work on a few days. The choice of a production system is even related to feeding issues. Salatin promotes an extensive grazing system for reducing feeding costs: Since layers are able to forage for highprotein insects in warm months, less concentrate feed is needed. The confined quarters of the field pen system keep feed in front of the birds at all times, an advantage if you want to encourage your birds to eat and grow quickly.

Note: The choice of a production system may be influenced by genetics. Cornish cross broilers are not known for foraging. They were developed for confinement systems and are relatively inactive, especially as they grow. The field pen system forces them to graze. Plamondon prefers two different systems depending on the type of bird: his family uses a free-range type system (colony) for layers but field pens for broilers. He says the broilers prefer to be in the shade and close to their feed anyway, so a pen is appropriate. Producer Kip Glass (22) did a study comparing pens to "day-range," and he prefers pens for broilers. On the other hand, layers are lighter birds and much more inclined to forage than the heavy Cornish Cross broilers. In the future, producers may have more options for broiler genetics adapted to foraging.

Integrating Poultry Onto The Farm

Animals and cropland have been separated in modern agriculture, in which livestock and feed-crop production are distinct industries. Range poultry production reverses this trend by reintegrating poultry with the land base as part of a whole farm system.

A permaculture concept called "stacking" combines several enterprises on the same piece of ground. Various species of domestic animals can be raised together to complement each other, creating mutually beneficial relationships (17). For example, Salatin keeps turkeys in his vineyard to control the grass and bugs; the vineyard shelters the birds.

As noted earlier, poultry production can be complementary to vegetable production. Chickens

may be confined in "chicken tractor" field pens or allowed free access to the garden at certain

times (23). Dr. Jim McNitt (24) at Southern University studies the fertility contribution of

pastured-poultry field pens integrated with vegetable production. Chickens also help to control

crop pests. They will eat insects in some crops, for example potatoes, without damaging the

plants. Researchers at Michigan State University (25) have studied the use of chickens and

geese in apple orchards; chickens were found to control insect pests while geese aided in weed

control. Chickens are sometimes used for tillage - clearing surface weeds and bulbs out of a plot

of land, scratching, and preparing the ground for vegetable planting. "Fold" houses in the U.K.

have allowed flocks of chickens to help glean fields after crops were harvested (11).

Poultry may share permanent pasture with cattle, sheep, and goats, improving the pasture

soil with their manure. As mentioned earlier, poultry contribute to cattle health by picking

apart dung pats that harbor fly and parasite larvae. Multi-species grazing is commonly employed

by pastured-poultry farmers. Several species of animals may be grazed together simultaneously,

or the grazing may be staggered to allow only one species at a time in the paddock. Multi-species grazing can aid in protecting poultry from predators that respect large animals. However, cattle and goats may disturb poultry housing and feed. Producers with field pens have complained of goats jumping on top of the pens and damaging them. Cattle may also disturb field pens, but they do not usually interfere with netting. Cattle have been known to kick turkeys, causing injury. It is necessary to exclude ruminants from poultry feeding areas to prevent foundering. This can be done with netting or wires.

Other Benefits Offered by Poultry

Some people keep chickens for tick control.

Turkeys were used in the past for insect control in crops, such as in tobacco during colonial times. Turkeys are more aggressive foragers than chickens.

Weeder geese were used on a large scale in California in the '50s to weed cotton fields before the widespread use of herbicides. Geese have been used successfully to weed crops such as strawberries, potatoes, and onions. Geese have a strong preference for young grasses.

Ducks, more commonly eaten in Europe and Asia than in the U.S., have been used to control aquatic plants in ponds, especially duckweed and pondweed. Muscovy ducks have been used for fly control on dairy farms. Ducks and geese provide insect, snail, and slug control.

Guineafowl, considered luxury food in Europe, are good foragers, controlling insects in pastures and gardens. Because of the noisy calls they sound when alarmed, guineafowl and geese can also act as "watchdogs".

A good community project

Further Sections

To continue reading the article, please click on the links below

Source: National Center for Appropriate Technology (NCAT) - February 2002