The Commercial Egg Industry Should Consider Controlled Atmosphere Stunning for Spent Hens

By A. Bruce Webster, Poultry Scientist. University of Georgia, Cooperative Extension Service. Unlike the broiler industry, where individual companies maintain ownership of flocks through farm production and processing, commercial egg flocks sent for slaughter are sold to a fowl processing company.The processing company catches and transports the hens from the farm. Egg companies typically do not see themselves as being responsible for a hen’s welfare once ownership of the bird is transferred, and what happens to spent hens after that tends to fall under the radar.

Caged egg-type laying hens are prone to develop osteoporosis. These hens have been found to have high rates of bone breakage after being removed from cages, and each handling step thereafter adds to the numbers of hens with broken bones (Gregory and Wilkins, 1989). Strong muscle contractions during electrical stunning induce more bone breakage, which is unlikely to be a welfare problem but does affect product quality.

Spent hens also differ from broilers in that they are much more active, agile and reactive to disturbance. Modern electrical stunning systems for chickens have been designed for broilers, and when properly adjusted are effective for these birds. A market weight broiler is heavy and not physically fit. It is unable to struggle for long in a shackle and after a short time hangs passively as it travels toward the stunner. Unless broilers are disturbed just before the stunner to make them struggle, they typically make good electrical contact when first presented and are immediately stunned. In my experience, the situation is more variable for mature birds such as spent hens. They are more likely to struggle in the shackle and lift their bodies away from the stunner bath, reducing the probability of making good electrical contact with the stunner. They also can flex their necks so that the head is not the first part of the body to contact the stunner, and the bird gets a pre-stun shock. Birds start back from such a shock and can receive more than one pre-stun shock before being captured by the stunner. Since the head is not part of the electrical contact, these shocks do not stun the bird. Pre-stun shocks tend to make hens even more mobile in the shackles, enabling some to miss the stunner altogether by riding up on the bodies of adjacent birds.

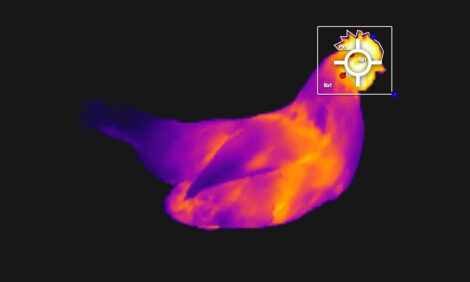

The twin problems of bone breakage and pre-stun shocks make controlled atmosphere stunning (gas stunning) an option that fowl processors should seriously consider for spent commercial laying hens. Many spent hens have at least one broken bone by the time they reach the shackling station, and no doubt experience pain when picked up. All gas stunning systems stun birds before they are placed in the shackle, thus eliminating fear, stress, pain, and further injury at that point of handling. Gas stunning eliminates pre-stun shocks. Although most fowl processors take many spent breeders, which do not suffer from bone fragility, elimination of pre-stun shocks would still make gas stunning an attractive option, at least from an animal welfare perspective. Incidentally, the job of shackling birds becomes much easier for handlers as well.

Why should this be the concern of the egg industry? The bone fragility and reactive capability of spent layers at the stunner create serious animal welfare problems. The American public probably will not appreciate the significance of the ownership transition from egg company to fowl processor, and I believe will hold the commercial egg industry responsible for whatever happens to spent hens. Egg companies will be seen as having the foresight to know what happens to hens after flocks are removed from farms. Since the animal welfare problems described above can be alleviated by controlled atmosphere stunning, this technology may benefit public perception of the egg industry. It may also be possible that fowl processors could achieve some improvement in product quality by reduction of bone breakage.

What can the commercial egg industry do to influence the practices of the fowl processing industry? Maybe little directly. On the other hand, an effort by egg companies and egg industry associations to engage the fowl processing industry in dialogue to raise awareness of the importance of spent hen welfare to the egg industry as a whole, and to discuss standards for fowl processing that would match those for other aspects of egg production, as outlined in the UEP Animal Husbandry Guidelines, might be productive. As part of this, fowl processors could be encouraged to consider the merits and feasibility of the different controlled atmosphere stunning systems on the market.

It is important to note that these suggestions apply specifically to the slaughter of spent commercial laying hens and, secondarily, spent heavy fowl. Other poultry industry sectors do not necessarily have the same problems and controlled atmosphere stunning may not offer the same benefits for them.

Reference:

Gregory, N.G., and L.J. Wilkins. 1989. Broken bones in domestic fowl: handling and processing damage in end-of-lay battery hens. British Poultry Science 30:555-562.