Cleaning and Disinfection of Layer House Systems for Shell Egg Production

The poultry industry is a dynamic one and the egg producers, who are part of it, are no exception to the rule, according to Karel Bossuyt and Lieven Dambre from CID Lines.The traditional (battery) cage ban that was opposed in EU beginning 2012 is a prime example of how the poultry production industry needs to be flexible and ready for changes in order to be sustainable today and in the future.

The main goal of the ban of traditional cages is to raise the hen welfare standards but what about the hygiene standards in the alternative layer housing systems? The cages scored well on egg and hen hygiene and had less dust flying around in them. Because the hens are occupying the layer house up to 58 weeks, a high level of soiling (manure, feed, dust, scale, etc.) can be expected.

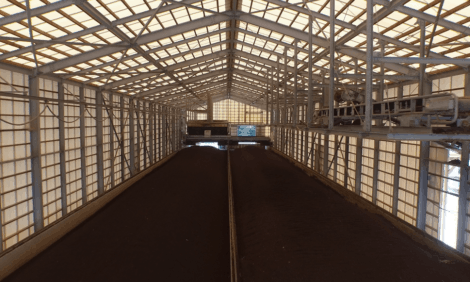

Which layer housing systems will also score well in terms of hygiene and are they easy to clean? The possibility to thoroughly clean and disinfect the layer house only comes by every 12 to 13 months. Farmers should take this opportunity to aim for a pathogen–free (Salmonella etc.) house during this all-out phase before introducing the new flock into the layer house.

Swab Analysis

A trial has been conducted by Karel Bossuyt, in which five different layer housing systems where cleaned and disinfected. A comparison was made in labour, water consumption, product consumption and cleaning- disinfection results between the different systems. The same cleaning company cleaned and disinfected all houses. In this way, the way of working in terms of people and the equipment they used could not negatively influence the cleaning and disinfecting results (C&D results). The C&D results were analysed by swabbing (RODAC plates). After incubation the remaining colony-forming units (CFU) are counted in order to analyse the hygiene result. Twenty-five plates were taken per layer house and this twice, one after cleaning and one after disinfection.

Three plates on the drinking system (pipe & drink cup), one on the egg belt, one on the hopper, one in the egg storage room (floor), one on the air inlet (grid), three in the laying nest grid), three on the laying nest side panels, two on the ceiling, four on the floor, three on the feeding system, two on the wall and one in the packing area.

The number of CFUs per plate are categorised by range and are given a score (table 1). The swabbing, the incubation, reporting and interpretation of the scores are executed by an official and independent laboratory. In this case it was done by dgz (Animal Health Care Flanders in Belgium.)

| Table 1 | |

|---|---|

| CFU per plate | Score |

| 0 | 0 |

| 1 - 40 | 1 |

| 41 - 120 | 2 |

| 121 - 400 | 3 |

| > 400 | 4 |

| TNTC | 5 |

There are three possible interpretations of these results:

- score: <1.5: C&D procedure has been done properly and is approved.

- score: 1.5 to 3.0: C&D procedure has to be done again before a new flock can be introduced to the layer house.

- score: >3.0: C&D procedure has to be done again and this by a professional cleaning company, before a new flock can be introduced to the layer house.

Dare to Compare

The five systems that were compared are an enriched cage system with a central egg collection belt (Easy80/100, Fienhage), a traditional cage system (Univent, Big Dutchman), an organic free-range system (side band nesting, Vencomatic), an enriched cage system with colony housing (Specht) and an alternative housing system with winter garden (Natura and manure pit system, Big Dutchman).

It clear that each system has its own specific design and therefore the critical points for each housing system will differ. These Critical Control Points (CCPs) will influence the cleaning result in terms of labour costs. The time and personnel spent on dry and wet cleaning are taken into account. Some systems are easier to clean than others. Of course, when something is difficult to clean, the risk of it not being cleaned properly is higher. This will reflect in the disinfection result as well because heavy organic soiling will influence the disinfection negatively. This cause and effect mechanism creates a vicious circle where some spots can really become infection sources that recontaminate each new flock over and over again.

The detergent used for cleaning was KENOSAN (CID LINES) at 1.5 per cent, except for the traditional cage system. Here, only water was used for cleaning. The detergent was applied by a foaming. For disinfection, two product were used, or VIROCID (CID LINES) or CID20 (CID LINES). Both products are well tested and have a strong bactericidal, virucidal and fungicidal action. The difference was situated in the application of the disinfectant. Some fogged (at 20 to 25 per cent) the disinfectant, and others foamed it (wet disinfection, at one per cent). In table 2, the different methods are specified.

| Table 2 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity | DRY CLEANING | WET CLEANING | Product consumption | Average cleaning score | DISINFECTION method | Product consumption | DISINFECTION | ||||

| hours | n people | hours | n people | hours | n people | ||||||

| Easy 80/100, 2 floors | 60.000 hens, 1920m2 | 36 | 5 | 278 | 5 | 60 L | 3.9 | Thermo fogging | 30 L | na | na |

| UNIVENT, traditional cage | 13500, 800m3 | 20 | 2 | 60 | 5 | WATER | 4.6 | Sprayer nozzles | na | na | |

| Organic, free range | 7200, 1200m2 | 10 | 2 | 100 | 3 | 40 L | 3.8 | Termo fogging | 10 L | na | na |

| Specht, 2 floors enriched colony | 24000, 780m2 | 25 | 3 | 120 | 3 | 20 L | 3.1 | foaming | 20 L | 30 | 2 |

| NATURA, manure pit + wintergarden | 30000, 3500m2 | 70 | 2 | 130 | 3 | 60 L | 2.7 | foaming | 40 L | 3.5 | 2 |

| thermo fogging | 20 L | na | na | ||||||||

Clean, Cleaner, Cleanest

In the easy80/100, the laying mats need to be pulled out of the nests and should be cleaned outside the layer house. Because this is a two-floor system, the dust and manure that comes from the 2nd floor needs to be evacuated to the 1st floor. A lot of dirt gets stuck between floors. These are the main two reasons why this system is more labour-intensive in terms of cleaning.

The traditional cage system was cleaned only with water, which results in a poor average cleaning score of 4.6. In the organic system grids, drinkers and feeders are dismantled and cleaned outside the house. This explains the high number of hours and people needed to clean a relatively small surface. The Specht Comfort two-floor system proved to be fairly easy to clean. It scored on average 3.1. The critical points were the laying nests. The Natura manure pit system has no automatic manure belt but the drinking and feeders could be winched up, which made the removal of manure easier. However, all the floor grids needed to be dismantled and cleaned outside the layer house. The laying mats are also removed and cleaned in an automatic system outside. The cleaning score was 2.7 so a dry cleaning phase, which is very labour-intensive but if done properly, it resulted in a very good cleaning score.

To Fog or Not to Fog

Labour cost and product consumption is one thing but the score at the end of disinfection needs to be equal or below 1.5 in order to consider the C&D protocol to be successful. The graphs in table 3 the disinfection scores are shown for each swab point (25), the average disinfection score and the norm (DGZ).

Average disinfection scores layer housing systems

Looking at the disinfection results, in the traditional cage system and the organic free-range system, the disinfection did not was successful enough with scores of 1.7 and 1.6, respectively. In the traditional cage, only water was used for cleaning. The organic load was too high when the disinfection phase started. The nests still scored very highly. The automatic sprayer system does not reach the nests efficiently.

The organic system only fogged 10L of CID20. With such a high level soiling system, a wet disinfection is absolutely imperative. It will improve the contact of disinfectant with the surface dramatically. The grids are made of wood and therefore scored the worst: 3.5!

The easy80/100 just performed on the norm with 1.5. The floor and packing room score still above the norm.

Definitely the best scores were achieved with the enriched cage colony system and the Natura manure pit system with wintergarden with scores of 1.1 and 1.3, respectively. The bad score on the drinking system (3.3) in the Natura layer house was due to the fact that the swab was taken underneath the drinking cup. The drinking lines were winched down at the moment the disinfection was done. This place was not reached by disinfectant. Without this error, the score would be 0.7. Both applied the disinfectant VIROCID by foaming. A simple foaming cup lance was used (see picture). In the Natura system, a fogging phase was also done after the wet disinfection. The score afterwards dropped from 1.3 to 0.8.

Layer housing system can influence the dry and wet cleaning phase but when this is done properly, the disinfection results should not be influenced by them. Foaming the disinfectant when correctly applied (dosage) proved to be crucial for a clean and pathogen-free layer house. Fogging should be seen as an additional measurement for disinfection executed after the wet disinfection.