A Salmonella Control Programme

A combination of all measurements taken to reduce the risk of Salmonella introduction and spread, explained by Lieven Dambre, Product Manager for CID Lines.Over the last decade there was a dramatic increase of human cases of salmonellosis and Campylobacteriosis in most Western Countries.

Figures of epidemiological research indicate that about 10 per cent of human salmonellosis and nearly all Campylobacteriosis cases are caused by consumption of contaminated poultry meat.

There are more than 2500 Salmonella serovars recorded but the European commission observed flock prevalence for the five most reported serovars, which are S. enteritidis (10.9 per cent), S. typhimurium (0.5 per cent), S. infantis (2.2 per cent), S. mbandaka (0.4 per cent), S. hadar (1.1 per cent) and others (6.6 per cent) (EFSA Journal, 2011).

The prevalence of these serovars is country specific. Because of this hazard to public health the European Union imposed in 2003 a regulation (EC) No. 2160/2003 on the control of Salmonella and other specified food-borne zoonotic agents.

For the poultry industry this meant a monitoring programme was installed and on rules were established to avoid the introduction of Salmonella on the farm.

Cause and Effect

Today eight years later several studies show that the EC regulation did not miss its effect on Salmonella prevalence.

In a field study in the Netherlands (Van Der Fels-Klerx HJ et al., 2008) for example data was collected during the period 2002 through 2005 and from six sampling points in the chain, covering hatchery up to and including processing.

Trends in Salmonella prevalence over years and seasons were analysed as well as the effect of slaughterhouse capacity on these trends. In addition, correlations between the occurrences of Salmonella at the various sampling points were calculated. The results showed a decreasing trend of Salmonella prevalence from 2002 through 2005 at all sampling points.

One Battle Does Not Win a War

EFSA also confirms a drop in the average salmonellosis cases since the implementation of the control plan however there is no reason to contemplate.

It must be considered as the first steps in the right direction. Yes we are off to a good start but there is still a lot of work to be done at every level (hatcheries, farms, transport and slaughterhouses).

Reducing Salmonella in the poultry production will be a constant battle on all fronts and the strategy for a combative programme must become an automatism in all countries throughout the whole production chain. So it’s needless to say vigilance and proactivity is still very much required on a daily basis to control Salmonella.

In this article we will refresh our memory on the how to act on farm-level based not only on the EC directive but also on the experience CID Lines has acquired in controlling Salmonella since the regulation was imposed.

The Weakest Link?

Salmonella and especially S. enteriditis can infect hatching eggs because there taking an invasion of internal organs place in the chicken and so Salmonella can be transmitted through the eggs from the parent poultry flock to the broiler. This is what we call vertical transmission. Salmonella can also be transmitted horizontally from the environment to the broiler.

In this case the infection cycle is 100 per cent oral-fecal and therefore apart from fecal and environmental contamination, the contamination to the egg is limited to the eggshell. It is clear that a control plan, focusing only on the vertical transmission by clinical treatment and eradication of the Salmonella positive parent flocks, is not effective when the horizontal transmission is not controlled.

The CID Lines' Salmonella programme covers both vertical and horizontal transmission routes and offers a clear guideline with hygiene solutions for each critical control point on the farm. As stated earlier all participants in the production chain are linked and therefore everyone has to make the effort to secure their part. One weak link can break the chain easily. CID Lines also has specific programmes for hatcheries and slaughterhouses but in this case we will focus on the farm-programme.

Prevention is Key

Research has shown that 30 per cent of Salmonella isolates are resistant for streptomycin, ampicillin, amoxillin and tetracyclin and about 12 per cent for nalidixin acid and trimethoprim/sulfamethoxazole. Furthermore it is shown that 42 per cent of the isolates are resistant for at least one antibiotic, 11 per cent for five antibiotics and all 49 S. Hadar strains were resistant for at least two antibiotics and most of them are resistant for three to five antibiotics (De Zutter Let al., 2000).

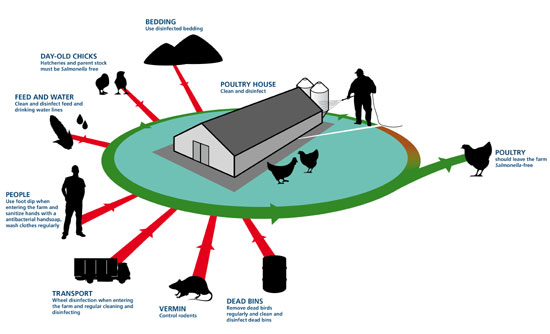

Next to a Salmonella free parent stock and hatcheries to obtain Salmonella free day-old chicks in terms of vertical transmission, CID Lines’ Salmonella programme defines 7 critical control points (see picture Salmonella programme) which are a potential danger for horizontal transmission.

It all starts with a clean and disinfected poultry house. Dominant types of Salmonella are easily transferred to the birds by insufficient hygiene in the house before arrival of the one-day old chicks. Furthermore Salmonella can survive in manure and dust for more than 30 weeks so following a strict cleaning and disinfecting protocol that has proven its efficacy is absolutely crucial to keep the infection pressure low.

The product duo KENOSAN and VIROCID will do exactly that job. An alkaline foam cleaner like KENOSAN to degrease and clean the building followed by the highly efficient disinfectant VIROCID to kill off 99,99 per cent of the remaining bacteria. Moreover both products are used and effective at very low concentrations which makes them very good value for money!

Secondly drinking water is an important vector for further spreading of bacterial contamination.

This indicates the importance of a correct disinfection of the drinking water during production. Drinking Lines should also always be cleaned out between flocks, especially to prevent biofilm build-up. CID Lines has a complete range of drinking water treatment products to clean, disinfect and acidify the drinking water such as CID2000, CID CLEAN, AGROCID SUPER oligo, etc. to ensure Salmonella free water of top quality and ditto performance of the poultry flock.

The poultry production is an industry on wheels and it’s therefore of vital importance that all outgoing and incoming traffic (chicks, bedding, manure, feed, slaughterhouse...) have been disinfected without exception.

A wheel bath or a sprinkler installation is of course all very nice but at farm level it’s just as efficient to have someone simply disinfecting the truck manually with for example a VIROCID solution of 0.5 per cent.

To conclude we look at the most discarded and forgotten measurement on the farm whilst it is probably the fastest, most simple and cheapest in order to prevent Salmonella spread: Disinfection of footwear and hand sanitizing with anti-bactericidal hand soap. A very small effort that really should become an automatism among farmers and workers because recent studies have again clearly proven that farm boots samples are an important risk factor with a Salmonella prevalence of 19.7 per cent! (Prev. Vet Med., 2011).

A Small Risk Repeated 1000 Times Becomes a Big Risk

Biosecurity is not about targeting on one or two possible contamination risk vectors and hoping you have made the right choice. Biosecurity is about controlling and addressing a whole series of little critical points.

It’s the combination of all measures taken to reduce the risk of introducing and spreading disease. Some may ask for more effort by the farmer than others but only by this approach infection pressure can be maintained at very low levels on the farm. Therefore CID Lines always offers a total bioprotexion programme, with the Salmonella programme being one of these, in order to achieve and guarantee results.

References

- De Zutter L. et al., 2000. Crates inoculate broilers with Salmonella and Campylobacter. World Poultry, 16, No 4,19.

- EFSA Journal 2011;9(3):2090. The EU summary report on trends & sources of zoonoses, zoonotic agents and food-borne outbreaks in 2009.

- Van der Fels-Klerx HJ et al., 2008. Salmonella prevalence in the broiler supply chain in the Netherlands.

- Prev Vet Med. 2011 Jan 1;98(1):39-45. Epub 2010 Oct 29. Sources of Salmonella contamination during broiler production in Eastern Spain., Marin C, Balasch S, Vega S, Lainez M