Ammonia Concentration Versus Ventilation Rate

Monitoring ammonia levels in poultry houses can help producers to adjust ventilation rates and thus prevent problems, say Michael Czarick (Extension Engineer) and Brian Fairchild (Extension Poultry Scientist) at the University of Georgia in the latest in the series of 'Poultry Housing Tips'.One of the biggest challenges with maintaining optimal air quality during cold weather is the fact that much of what we are trying to control is constantly being generated. For instance, if we had an empty house and filled it with smoke we could turn on a few exhaust fans and within minutes the smoke would be gone – problem solved.

But, when it comes to gases such as ammonia and carbon dioxide which are constantly being generated, it is a never-ending process to keep them under control. For example, during the minimum ventilation, “off cycle” ammonia levels will slowly rise as the ammonia produced by the litter builds. When the minimum ventilation fans turn on the ammonia levels will quickly decrease as fresh air is added to the house. But as soon as the exhaust fans turn off, the ammonia level will start to rise again and by the end of the “off cycle” it will be back to where it was prior to the fans turning on.

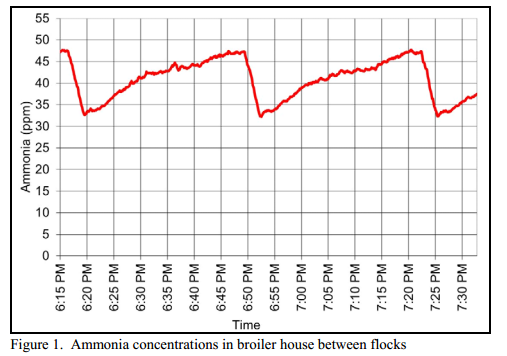

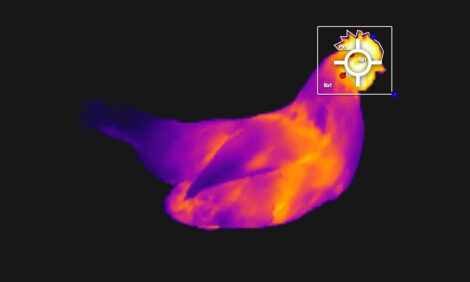

The cyclical nature of ammonia concentrations in poultry houses can an be seen in Figure 1 where between flocks two 48-inch fans were operating three minutes out of every 30 to help limit the build-up of ammonia and moisture.

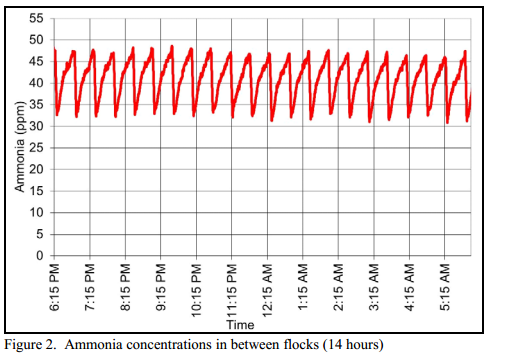

Though operating the exhaust fans lowered the concentration of ammonia in the air by approximately 15 parts per million (ppm), as soon as the fans turned off ammonia concentration started to rise and within 30 minutes, it was back to what it was before the exhaust fans turned on. The pattern continued for the next 14 hours of the study (Figure 2).

Little if any progress was made in lowering the overall average ammonia concentration.

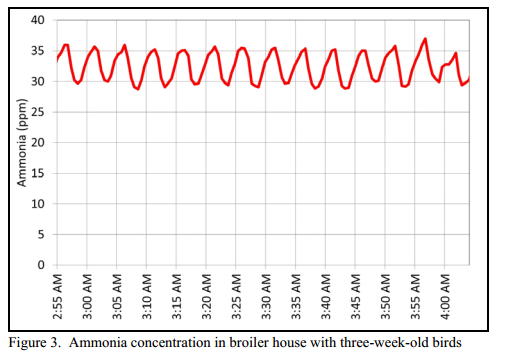

The same cyclic pattern of ammonia concentrations can be seen in Figure 3 where minimum ventilation fans were operating 90 seconds out of five minutes in a house with three-week-old birds. Minimum fan operation decreased ammonia levels by approximately 7ppm but by the end of the minimum ventilation fan “off cycle” they rose the same 7ppm. The average ammonia concentration remained essentially the same, 33ppm, over the course of the night.

For any minimum ventilation fan setting, the ammonia levels will tend to reach a level of equilibrium. In Figures 1, 2 and 3, though the minimum ventilation fans reduced ammonia concentrations quickly, the reduction was temporary and over the short-term, average ammonia levels did not significantly change. The equilibrium ammonia concentration can, of course, be lowered by increasing the minimum ventilation rate.

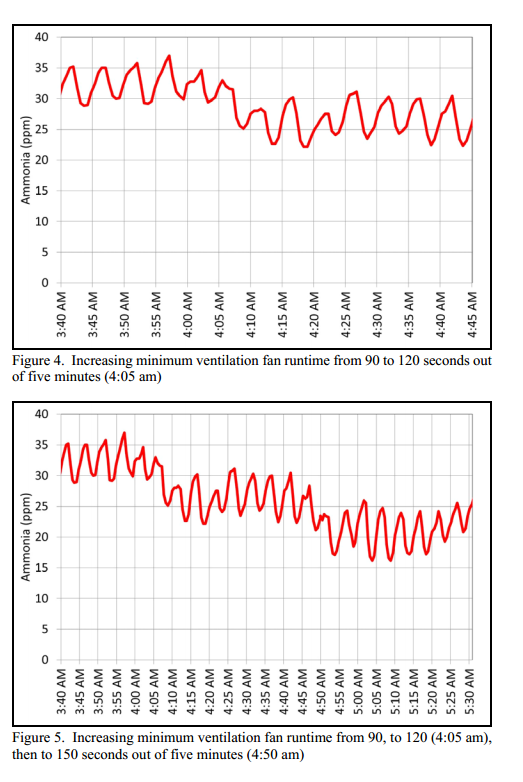

An important fact to keep in mind is that the reduction in the equilibrium or “average” ammonia concentration will be roughly proportional to the change in exhaust fan run-time. This means that in order to make large changes in average ammonia concentrations, relatively large changes in minimum ventilation fan runtime need to be made. For instance, the minimum ventilation fan run-time in the house illustrated in Figure 3 was increased from 90 seconds to 120 seconds out of five minutes (4:00am).

The increase in fan run-time of 25 per cent reduced average ammonia concentration by 22 per cent (from 33 to 27ppm; Figure 4). Increasing fan runtime from 90 to 150 seconds, a 40 per cent increase, reduced ammonia concentration by 35 per cent (from 33ppm to 22ppm; Figure 5).

So in short, if you want to cut your ammonia levels in half, double your minimum ventilation rate. This holds true if the ammonia concentration is 80ppm and you want to drop it to 40ppm or even if the ammonia concentration is 40ppm and you want to decrease it to 20ppm.

Does this mean that if you have high ammonia concentrations that you may have to double or quadruple your minimum ventilation rates indefinitely? Not necessarily. Though high minimum ventilation rates will help to keep ammonia levels to a minimum, they will also tend to address the root cause of ammonia: litter moisture.

Over time, higher ventilation rates will tend to reduce litter moisture levels, which in turn will reduce the ammonia generation rate, which in turn leads to lower ammonia levels and an overall reduction in the minimum ventilation rate required to keep ammonia concentrations to a reasonable level.

Can this method of ammonia control prove expensive? Sure. But, the fact is that once you have an ammonia problem it is expensive to solve. The key to keeping ammonia levels and heating costs to a minimum is preventing high ammonia levels in the first place. Between flocks, remove cake from the house as soon as the birds leave and ventilate the house to help dry the litter. Use a litter treatment according to manufacturer’s recommendations prior to chick placement.

Most importantly, closely manage house moisture levels by monitoring the relative humidity of the air in the house. The relative humidity of the air in a house is an indirect measure of litter moisture. Generally speaking, the ideal relative humidity would be approximately 50 per cent. As the relative humidity of the air in the house climbs, so does litter moisture. Increased levels of litter moisture results in higher ammonia production rates.

If you allow the average relative humidity climb to 70 to 80 per cent, you will have wet litter and high ammonia levels, which can only be reduced to acceptable levels by a dramatic increase in minimum ventilation rates.

To avoid this situation, make relatively small adjustments to the minimum ventilation rates on a daily basis. Record the relative humidity in your houses each morning. If you see the relative humidity climbing, make larger increases.

Bottom line: don’t wait until you have an ammonia problem to try to solve it. After all, “an ounce of prevention is worth a pound of cure”.

February 2015