Delivering Chicks in Prime Condition Round the Globe

A profile of the Transportation departments of Cobb, which deliver feed, hens and pullets, hatching eggs and day-old chicks to customers in many markets around the world. The article is published in the latest issue of Cobb Focus.

It is 2am and the Cobb chick delivery drivers based in Siloam Springs, Arkansas, have just pulled into the hatchery from a previous day-old chick delivery. They will unload the empty chick boxes, clean and disinfect the vehicle, load the next delivery, and start out again – sometimes without even seeing their family who may be only a few miles away.

These events are likely to be repeated several times a week by the dedicated people in Transportation departments for Cobb worldwide. They are responsible for many tasks including feed delivery, hen and pullet shipments, picking up the hatching eggs from multiple farms and delivering them to the dedicated hatcheries, and finally delivering day-old chicks to customers in many markets around the world.

The Transportation group provides an essential function, which the company relies on for its efficient delivery of quality products and professional communication with the customer.

Delivering products on time and in the best condition calls for highly specialised equipment for each area. Feed trucks have electronic cab controls for ease in unloading feed out on the farms. Egg transport vans have specialised suspension systems to give the hatching eggs the smoothest ride possible to avoid breakage.

The chick delivery trucks are the most specialised of all, as transporting baby chicks is a very real challenge. A chick delivery may be as short as one mile requiring only a few minutes to complete from the hatchery – or as far as 1,900 miles encompassing 40 to 42 hours of travel. The volume of chicks can be as small as several hundred to over 75,000 per delivery.

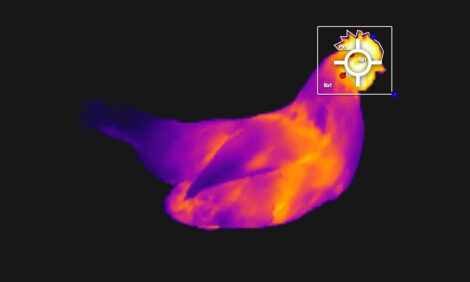

Outside temperatures will vary with the season from highs over 100°F (38°C) to lows of minus 20°F (-29°C). Yet, through all these varying conditions, the chicks must remain inside the specially designed climate-controlled van trailer at a comfortable temperature with plenty of air exchange to keep them active and healthy.

* "Drivers have to respond to delivery times dictated by international flight schedules" |

On-board power units supply the energy needed to keep the ventilation equipment operating continuously. Many vans even have two electrical generating units on board, each capable of powering the full load in case one unit fails. Readings from several temperature sensors positioned throughout the trailer show up on the control panel in the cab and are regularly monitored by the driver. GPS technology allows the logistics managers to know the exact location of the trucks at any time during the delivery.

All of this technology means nothing without the professional, reliable and committed drivers who pilot their vehicles and maintain surveillance of the cargo to the ultimate destination. Jim Gottsponer, transportation manager for the US, reports that our drivers and vehicles are over 99 per cent in compliance with Department of Transportation roadside inspections. This excellent rating is due to the efforts of the operators to keep the equipment in the best condition.

In Brazil, the parent stock chicks are delivered through a contract with another poultry company, Globoaves. The dedication of the drivers is best summed up by Globoaves driver, Roberto Jorge Maciel. He says: “I like everything I do, especially working for a company that is very strict but treats everyone with respect. It is a big responsibility because the company trusts me with its most important product.”

This professionalism is also reflected by the length of service of many of the drivers. “We just do not have turnover of personnel,” says Merrill Bishop, feed mill manager in Arkansas. For example, his drivers’ length of service for Cobb ranges from five to 23 years, and this is typical rather than the exception throughout the company.

International chick deliveries are portrayed by the transportation regime followed at Cobb Europe. The job for Iain Bolton, chick vehicle driver for Cobb in the UK, revolves around the two 18-tonne vehicles that deliver chicks from the Elsing Lane hatchery to airports in the UK and mainland Europe. The drivers have to plan and respond to a wide range of delivery times dictated by international flight schedules. Movements of the vehicle are tracked by satellite – a requirement of European Union for all animal transport lasting more than eight hours. The route is planned by satellite navigation, which takes into account weight and height restrictions. The tachograph records speeds, distances travelled and the hours worked by a driver, and are capable of storing information in five languages.

Readings from the many temperature sensors at different points in the load show up in the cab and the driver is able to alter the temperature by one tenth of a degree at a time.

Concise planning and excellent team work is required to get feed, eggs and chicks moved when required and delivered on time to customers each and every day.

Shipping a live product creates additional demands on drivers, requiring them to maintain a constant vigilance on the environment for the chicks, road conditions and delivery times.

The absolute end goal of everyone is for the day-old chicks to arrive on the customer’s farm in prime condition, anywhere in the world.

December 2009