How Much Moisture Do Brooders Add to Poultry Houses?

Y. Liang and G.T. Tabler from the University of Arkansas report their study into the the contribution to moisture in the broiler houses from different sources, and from heaters of both the standard type (unvented; propane or natural gas) versus vented biomass heating systems. They reported their experiment in the Spring 2009 issue of the University's Avian Advice.Introduction

The vast majority of poultry growers use unvented heating units, i.e. brooders or space furnaces, to heat their poultry houses, using propane or natural gas as fuel sources. Record high propane/natural gas prices over the last two years have led a number of producers to explore the possibility of using biomass furnaces to provide heat in their poultry houses. A number of alternative heating systems exist with a price range of less than $10,000 to over $60,000 (Czarick, et al., 2008). Generally alternative heating systems are considered profitable if they are able to replace approximately 85 per cent of the propane use, but conventional brooder/space heating systems must still supply heat during peak demand (Wimberly, 2008).

While the main benefit of biomass furnaces lies in its potential fuel saving, an overall improvement in air quality in the house as a result of introducing “dry heat” is an additional benefit reported by furnace vendors and some growers. This claim is based on the fact that unvented heating units such as brooders or space heaters release water vapor as they generate heat, while vented systems leave the combustion byproducts outside and introduce heat into the houses by heat exchangers. Unvented propane heaters are estimated to add 0.000078 pounds of water vapor for each BTU heat generated (ASHRAE, 1985). Natural gas releases slightly more water vapor than propane per unit of heat generated. If “dry heat” releases less water vapor into the poultry house, this is likely to lower in-house ammonia and ventilation requirements because of drier litter conditions. However, water vapor from unvented conventional heaters is only a portion of the moisture load added to the house, and this portion varies both within a flock and among flocks in a year. It may represent a high proportion of the moisture load during the brooding stage in cold weather when feed and water consumption are low, but much less of the load as birds get older. We decided to study the relative contribution of moisture to housing environment and potential significance of the “dry heat” benefit based on available scientific data so that growers are equipped to make wise investment decisions with respect to the relative importance of “dry heat.”

Materials and Methods

This analysis was conducted based on weekly propane usage, feed consumption and water intake data collected from 18 winter flocks (flocks placed in November, December and January) raised at the Applied Broiler Research Farm (ABRF). When the authors carried out this study they assumed that, when relatively low levels of heating were required during mild weather (because of convenience and system efficiency) propane heating systems would be favoured over biomass furnaces.

Moisture loads in poultry houses consist of moisture generated by birds and water vapor generated by propane heaters. Moisture generation by birds included water intake from drinkers, water in the feed (assume feed moisture content of 13 per cent) and metabolic water generated through the digestion of feed. Yet some of the water in poultry houses is retained in the bodies of the birds. Therefore, the amount of water retained by the birds (water retention) was calculated.

Several assumptions were made to conduct the analysis:

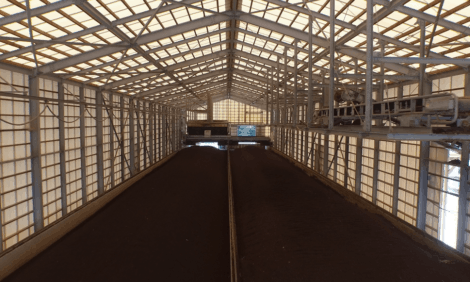

- Each 40 by 400 house was assumed to have 20,000 birds at placement, even though the actual bird number of each flock varied by target market weight and season;

- Water was assumed to make up 80 per cent of live weight of birds. This assumption was used to calculate the proportion water in the house that was retained by the birds (water retention);

- One BTU of propane generates 0.000078 (7.80 x 10-5) lbs of water vapour;

- One gallon of propane generates 92,000 BTU.

Further analysis was made on daily propane use during the first two weeks of the most recent five winter flocks raised in 2006, 2007 and 2008, and compared to daily moisture loads added by birds.

Results and Discussion

On average, birds drank between 1.5 to 2.1 pounds of water for every pound of feed consumed. Water consumption from drinkers was found to represent a majority of water added to the house. An average of 19 per cent of the water in the house was retained by the birds. This means that 81 per cent (range of 75 to 85 per cent) of the water that entered houses was released back into the house environment, by respiration and excretion (Figure 1).

If unvented propane heaters account for a large portion of the moisture added to poultry houses, it seems logical to assume that moisture addition problems would be worst in the winter months. Yet, analysis of propane consumption data from winter flocks revealed that unvented burning of propane generated an average of 23 per cent of total moisture loads in the first week of brooding, 11 per cent of the moisture in the second week, and five per cent or less in the remaining weeks (Table 1, Figure 2). Still, a major portion of the fuel combusted over the life of the flock is expended maintaining house temperatures of 85 to 90°F during these early weeks. In addition, the overall growth rate and settlement status may well be determined during these early weeks (Tabler, 2000; Tabler, 2003). Therefore, daily propane usage data from the five most recent winter flocks was analysed to get a better picture of moisture loads within the first two weeks of chick placement.

| Table 1. Weekly moisture loads generated by birds and unvented propane heaters | |||||||

| Week | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| Water generation from unvented burning (gallons/week) | 322 | 405 | 299 | 172 | 103 | 82 | 79 |

| Water from birds (gallons/week) | 1078 | 3206 | 5772 | 8443 | 10926 | 12964 | 14319 |

| Proportion from propane (%) | 23 | 11 | 5 | 2 | 1 | 1 | 1 |

(analysed for 18 winter flocks, per-house basis)

Figure 3 shows that moisture generated by propane burning represented 84 and 41 per cent of the total load on days 1 and 2, respectively. The percentage of moisture from burning propane decreased as birds grew, and stabilised at around 11 per cent during the second week of age. The dry heat from vented furnaces is clearly beneficial during the early days after bird placement when propane consumption is very high. Calculations show that on average the moisture load could be reduced by 20 per cent during the first week. While this reduction in moisture load would translate to drier litter conditions, and may allow the grower to reduce ventilation rates, it is important to remember that total moisture loads increase dramatically as birds grow, and moisture generated by birds remains the main reason for ventilation. While the benefits of dry heat from biomass furnaces become smaller as birds grow, it is also important to recognise that energy efficiency is also related to litter preparation between flocks. Growers that skip or short cut may save time but those who take the extra time to do the job right will likely find dividends in the settlement payment (Tabler et al., 2008).

(analysed on five winter flocks per house basis)

Summary

Several potential environmental and economic benefits have been reported for biomass furnace systems. While these benefits are often valid, it is important to see the whole picture. Vented furnaces produce dry heat that is reported to reduce in-house ammonia levels, decrease ventilation rates, improve litter quality and produce a healthier environment within the house (Wimberly, 2008).

Moisture load calculations based on propane usage data collected at the Applied Broiler Research Farm indicate that when using vented biomass furnace, about 23 per cent less moisture can be added to the indoor environment during the first week of brooding, when birds are very sensitive to house conditions and maintaining elevated temperatures requires the combustion of large amounts of propane. However, as birds grow bigger, more moisture is added by feeding and drinking, which represent more than 90 per cent of in-house water inputs from second week on.

References

ASHRAE. 1985. ASHRAE Handbook, 1985 Fundamentals. American Society of Heating, Refrigerating and Air-Conditioning Engineers. Atlanta, GA.

Czarick, M., B. Fairchild and D. Dartnell 2008. Alternative heating system... an overview. University of Georgia Corporative Extension Service, Poultry Housing Tips. December 2008.

Tabler, T. 2000. Brooding chicks in colder weather. Avian Advice 2(1):3-4.

Tabler, T. 2003. Early feed intake and bird performance. Avian Advice 5(1):13-15.

Tabler, T., S.E. Watkins and F.T. Jones. 2008. Litter preparation between flocks: management is the key. Avian Advice 10(4):4-7.

Wimberly, J. 2008. A review of biomass furnaces for heating poultry houses in the Northwest Arkansas region. Winrock International, Little Rock, AR.