Key Focus Areas of Development for the Future Within Animal Nutrition Technology

Richard Cooper, Managing Director, AB Vista, Hadden Graham, Technical Director, AB Vista and Mike Bedford, R&D Director, AB Vista discuss some of the key focus areas of development for the future within animal nutrition technology, highlighting the potential impact for customers and the marketplace.What are some of the focus areas that will have the most influence on AB Vista’s strategy in 2016? What makes these particular areas so compelling? [Richard]

As AB Vista were the first to bring the concept of phytase superdosing to the global market several years ago, ongoing research and customer experience has allowed us to build on our extensive knowledge in this field. In 2016, we look to bring this additional insight to the market to help producers derive maximum value from phytase application.

In addition to phytase, we look to contribute to improved industry understanding of fibre degrading enzymes, enabling poultry and pig producers to target a lower cost of production by achieving more consistent performance gains through xylanase application.

In addition to our products, we will continue to develop our technical services. In this area we will exploit recent advances in analytical technology, particularly related to NIR enabled feedstuff evaluation and accessibility, helping our customers improve raw material purchase decisions and feed formulation accuracy.

Phytase has been one of the most successful and most heavily researched feed additives of the last 25 years. Do you still see opportunities for the industry to get more value out of this enzyme? [Richard]

Absolutely yes, AB Vista continues to carrying out comprehensive research into both the enzymological functionality of various phytase molecules as well as applications in the animal. In both areas we have some very exciting developments that should be coming to the market in the next few months. For instance, new research has helped explain where the benefits from superdosing phytase are coming from. This increased understanding has led to superdosing being re-defined as using enough phytase to prevent the build-up of lower phytate esters such as IP3 and IP4 in the gut of the animal.

You have said that recent research concerning the degradation of IP3&4 “exposes differences between phytases that are not apparent when they are used at standard doses.” Can you elaborate on these differences? [Richard]

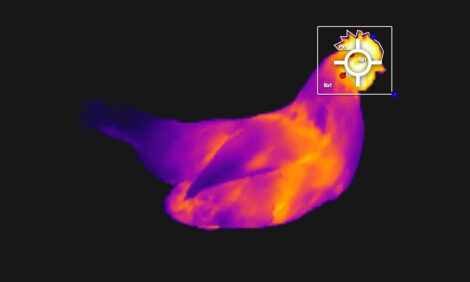

Standard doses of phytase, traditionally targeted at releasing an extra 1 kg of available phosphorus (avP) per tonne of feed, need to release approximately 2.5 of the 6 P units on the phytate (IP6) molecule. This results in the accumulation of lower phytate esters, primarily a mixture of IP4 and IP3, in the animal gut.

The anti-nutritive effects of phytate (IP6) in reducing nutrients availability, including minerals and proteins, are well known; what previously was less well known is that these lower phytate esters also have important anti-nutritive effects. What AB Vista did when introducing Quantum Blue superdosing was essentially destroy all phytate in the gut, releasing close to 5 of the 6 P-units.

Thus, by taking away the anti-nutritive effects of IP4-3, superdosing successfully improved animal performance. However, to achieve this, a phytase must be capable of degrading phytate, including lower esters, at low concentrations in the gut, and not all phytases are capable of doing this. Thus, with superdosing we are now seeing clear differences between phytase products in their ability to destroy phytate and thus improve animal performance.

The industry seems to find it difficult to differentiate between the multitudes of NSP enzymes offered. Can you shed any light on this challenge? [Hadden]

This probably stems from a poor understanding, of the mode of action of fiber-degrading enzymes (NSPases). Initially we all understood the use of NSPases to reduce digest viscosity in wheat- and barley-based diets, and to open up fiber-rich cell walls in the feed, for digestion of the nutrients by the animal’s endogenous enzymes.

However, in recent years we have come to understand better the role of the production in the animal gut of oligosaccharides by NSPases, and how these oligosaccharides can influence the gut microflora as well as the digestive processes. This can influence both gut health and nutrient availability, and thus have a major influence on animal performance. It is thus also now apparent that to see a consistent effect of NSPases, it is of paramount importance to use an enzyme product that is;

- well characterized (i.e. all enzyme activities present produce oligosaccharides that are positive for animal performance)

- quantified (ie all enzyme activities are subject to quality control in all batches), all enzyme activities can be easily and accurately analysed in feeds

- all enzyme activities are stable through feed processing and the proteolytic conditions of the animal gut.

Research would indicate that this is best achieved in corn- and wheat-based diets through the use of well characterized, highly stable single-enzyme xylanase-based products that are not susceptible to the xylanase inhibitors found in feed.

Dr. Mike Bedford argued in mid-20141 that there is a gap in our understanding of the efficacy of NSP-degrading enzymes or proteases when used in the presence of a phytase. Have you made any progress in addressing this question? [Mike]

There is a reasonable amount of data in the literature which suggests that the energy and amino acid sparing effects of NSPases and phytases overlap to some degree, such that the value of one in the absence of another is greater than when they are combined. This is to be expected as there is only so much “undigested” energy or amino acids at the end of the small intestine. And any enzyme that improves digestibility of either will reduce the amount of undigested material remaining for the next enzyme to work on.

This is classic law of diminishing returns and as a rule of thumb the energy and amino acid matrices of an NSPase and phytase should be reduced to 80% of the value that would be used if either was used uniquely. In practice, since matrices to date for NSPases and phytases are generated in diets which generally do not contain any other enzymes, this means that the energy and amino acid matrices of any NSPase and phytase should be discounted if they are to be combined. So 1 + 1 = 1.6 in effect.

Proteases are in a similar situation; they also work on the undigested fraction, and it is unlikely that the undigested amino acids which are made available by a phytase or NSPase would be unique and distinct from those released by the protease. As a result the value of a protease is equally reduced in the presence of a phytase, an NSPase and even more so if the phytase and NSPase are combined.

Our own data, which has evaluated a number of proteases including a number of available commercial proteases, has confirmed their utility is limited in a diet which already contains a phytase. Thus the end user needs to determine whether the value created by a combination of enzymes, given that the response to each successive enzyme reduces the value of all, is justified given the costs of inclusion. In some cases it may, for example, be better to increase phytase dose than include a protease.

There has been some debate recently around whether our industry might be over-feeding calcium. What are the implications of widespread Ca:P imbalance for AB Vista’s phytase strategy? This would seem to be a question of awareness-raising among the feed manufacturers and farmers. [Mike]

Even in the absence of a phytase, too much calcium in the diet results in precipitation of Ca phosphate in the small intestine, which reduces the availability of phosphorus. This is not an issue if phosphorus is in excess of requirement, but in most situations this is not the case. The result is that too much calcium can result in a deficiency of phosphorus.

A further and additional problem is that high Ca diets reduce the efficacy of phytases, such that the amount of phosphorus released is less than expected.

This is exacerbated by the first problem, and thus high Ca diets really need to be avoided if phytase use and thus animal production economics are to be optimized. The measure of whether you have too much calcium is not simply the total amount of Ca in the diet, although this is extremely important. It is also related to the ratio between Ca and P. If you have a high Ca diet but there is also a lot of P, then the precipitation of CaP will not impact the performance of the animal too drastically as both minerals are oversupplied (P pollution and diet costs will suffer, however).

Thus, the consequence of a high Ca diet is greatest if the ratio between Ca and P is also high, and as a result both measures should be considered simultaneously. Analysis of a wide range of feeds has established that actual dietary Ca can be higher than formulated, in fact we have frequently seen diets ~20% higher than the value formulated. Part of the reason is that limestone is cheap and thus may be used to make batch weights up to target if they are light. Also, limestone is used as a flow agent in soya bean meal which is often not accounted for by nutritionists.

What’s changed in the last 12 months in the field of raw material analysis? What does the future look like for NIR enabled feed analysis? [Hadden]

Feedstuff purchase and feed formulation has been relatively unchanged over the past half-century, with decisions based on parameters such as moisture and protein content as well as bushel weight.

The introduction of Near-Infra Red Reflectance (NIR) technology around 40 years ago helped reduce the cost and increase the speed of analysis, but didn’t really change the basis on which decisions were made. However, in the past few years changes in NIR hardware and software have opened up new opportunities. Firstly, internet technology has allowed NIR units web-enabled access to the latest up-dated calibrations on a pay-by-use basis, without the need to either purchase or update these calibrations.

Secondly, NIR calibrations have been developed for decision-critical parameters such as cereal energy value, digestible amino acids and reactive lysine. Feedstuff and feed analysis has moved into the 21st Century, and AB Vista is pleased to be able to offer the latest developments in this technology to customers through the AB Vista Feed Quality Service. In 2016, we will also look to offer our customers even more, with the introduction of miniaturized, hand-held NIR hardware. This innovation will allow immediate determination of a wide range of nutritional parameters, anywhere from the field to the feed mill.

What can the industry expect out of AB Vista in 2016? [Hadden]

During 2016 the industry can expect AB Vista to continue to provide new and innovative technical applications within our core products areas, enzymes, live yeast and betaine. As with phytase superdosing, which we introduced a few years ago, we expect these innovations will change the way the industry apply and the value they extract from these products. These product developments will be supported by a range of new and unique services focused on adding value to our customer’s businesses.