US Poultry Industry Manual - laying hen numbers and location

Part of Series:

< Previous Article in Series Next Article in Series >

Editor's Note: The following content is an excerpt from Poultry Industry Manual: The Foreign Animal Disease Preparedness and Response Plan (FAD PReP)/National Animal Health Emergency Management System (NAHEMS) Guidelines which is designed to provide a framework for dealing with an animal health emergency in the United States. Additional content from the manual will be provided as an article series.

Producing eggs for human consumption is a major agricultural industry in the United States. In the 1950s and 1960s, egg production was concentrated in the southeastern United States where producers put up inexpensive houses and utilized regulated railroads to bring in feed and ship eggs all over the country. As railroads were deregulated, southeastern producers lost their economic advantages and much egg production moved to the Midwest. Most commercial egg production now occurs in the Midwest, eastern areas of the United States, and in California.

According to the American Egg Board, 192 egg producing companies with flocks of 75,000 hens or more account for 95% of all layers in the United States. In 2010, there were 61 companies with 1 million-plus layers and 13 of those companies own 5 million-plus layers. In 2009, the average number of laying hens in this country was 280 million with an average daily rate of lay of 75%. Large commercial producers tend to be highly automated, however, hand gathering is still practiced on some larger operations in western states where labor is readily available. The leading egg-producing states are listed in Table 1. The five largest egg production companies in the United States own approximately 50% of all egg-type chickens in the USA. These companies are listed in Table 2.

Table 1. Leading Egg Production States (2012) |

||

National Ranking |

State |

Millions of Layers in Production |

1 |

Iowa |

52.3 |

2 |

Ohio |

26.9 |

3 |

Pennsylvania |

24.4 |

4 |

Indiana |

22.8 |

5 |

California |

18.9 |

Table 2. Leading Egg Production Companies (2012) |

||

National Ranking |

Company |

Millions of Layers in Production |

1 |

Cal-Maine Foods |

33.5 |

2 |

Rose Acre Farms, Inc. |

23.7 |

3 |

Moark, LLC |

14.9 |

4 |

Daybreak Foods |

13.5 |

5 |

Rembrandt Enterprises |

13.4 |

In-Line Egg Farms

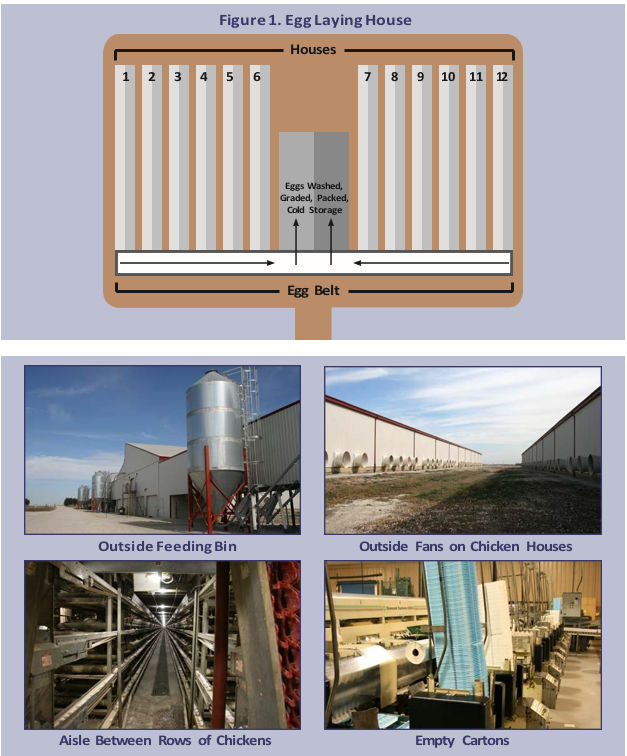

In-line egg operations are characterized by an automated egg collection system that carries eggs directly from chicken houses to the egg processing plant (building). These farms produce, process, pack, and ship eggs at one location. Large commercial “in-line” farms containing 50,000 to 6 million laying hens produce over 85% of table eggs in the United States. The average number of chicken houses in a large, integrated egg production complex is 10 and a complex may consist of 15 or more houses. Each house contains 50,000 to 350,000 laying hens. In-line chicken houses are highly-automated and eggs are moved on egg conveyor belts through enclosed passageways in a line to a processing building where eggs are processed within 24 hours after being laid. During processing, eggs are washed to remove fecal material and stains from shells, rinsed with a sanitizer, dried, candled to remove eggs with defects such as cracks or blood spots, weighed by computerized electronic scales, sorted by size, graded, and packed into cartons by automated equipment. Automated, high speed machines may process up to 400 cases of eggs per hour. A large number of chickens is required on the farm to keep machines operating at capacity. The day on which USDA-graded shell eggs were packed is shown on the carton by a Julian date.

Off-Line (Nest Run) Egg Farms

“Nest run” or “off-line” egg farms do not have a processing facility and typically consist of one or two chicken houses which lack processing equipment. Nest-run egg operations currently range from about 75,000 to 500,000 hens and eggs are collected in henhouses either by hand or by egg belt and moved to the egg room. In the egg room, they are placed on egg flats (fiber or plastic) and are then packed onto farm pallets or sometimes farm racks. Off-line eggs are packed “as is” without having been washed, sized, and/or candled for quality. Full pallets are placed in a refrigerated cold storage room. Nest run eggs may be held at their production farms for 2 to 4 days under refrigerated conditions after being laid, though some farms may ship the eggs quicker without the need of refrigeration.

Niche Market Egg Farms

Niche market farms account for less than 10% of eggs produced in the U.S. but account for the majority of egg production farms. These farms include small and large cage free, aviary-housed, free range, organic, and nutraceutical operations, and such farms may have several hundred to several thousand hens. In some cases, these farms house up to 50,000 to 75,000 hens. Smaller farms with less than 10,000 laying hens are likely to hand gather the eggs, but larger farms depend on mechanical gathering using egg collection belts to gather eggs from nests. Eggs produced on niche market farms may be marketed at the farm, brought to market by the farmer, or picked up by a processor.

Capital Investment

A typical Midwest multi-age, in-line egg production facility contains 1.5 to 4.0 million laying hens. With a 75% average rate of lay and eggs priced at $0.95 per dozen, 1.25 to 3.0 million eggs produced each day have a market value of $98,960 to $237,500. Typical modern in-line egg production operations in the Midwest may have chickens in cages with 67 square inches per bird, grading and packing equipment, egg-breaking machines to produce liquid whole eggs, and rooms for packing, cooling, and storing eggs. Capital investment for this type of facility ranges from $24 million for an operation with 1 million chickens ($24/hen) to $80 million for a 4 million bird complex ($20/hen). Maximum egg storage capacity in cooler rooms at most egg production premises is limited to the number of eggs produced during a period of 48 hours.

Reference: "USDA APHIS | FAD Prep Industry Manuals". Aphis.Usda.Gov. 2013. https://www.aphis.usda.gov/aph...

The manual was produced by the Center for Food Security and Public Health, Iowa State University of Science and Technology, College of Veterinary Medicine, in collaboration with the USDA Animal and Plant Health Inspection Service through a cooperative agreement.