Litter Preparation Between Flocks: Management is the Key

G.T. Tabler, S.E. Watkins and F.T. Jones of University of Arkansas report on their experiments with various litter treatments for broilers in the Winter 2008 issue of the Avian Advice.

Ideal Litter Conditions

Proper litter conditioning is an essential tool of good management for keeping flocks healthy and profitable.

Conditioning litter between flocks addresses where the birds live, which is the most crucial aspect of the poultry house environment. Ideal litter is loose and free flowing (friable), not too dry or too wet (20-30 per cent moisture is ideal), low in ammonia (less than 20 parts per million), uniform particle size (no large clumps) and contains a minimum load of insects.

Moisture is the key factor which influences litter quality. Allowing litter cake to remain in a facility can trap moisture in the litter, which will promote bacterial growth, pathogen development and ammonia release once the house is closed and re-warmed for the next flock (Watkins, 2001). In fact, recent information suggests that poor litter conditions cost the grower an average of $960 per 20,000 bird house (Ritz et al., 2005).

Litter Preparation History

Prior to World War II, the poultry industry primarily involved small, privately owned flocks. Neither nutrition nor disease control principles were well understood so frequent litter clean-out was seen as necessary and labour was plentiful. However, the start of the War meant that labour and materials became scarce, while the war effort increased demand for poultry products. This situation forced producers to use built-up litter rather than clean out one or more times per flock. Interestingly, during this time period, poultry researchers discovered that birds grown on built-up litter and fed nutritionally deficient feeds were healthier and grew faster than birds fed the same feeds on new litter (Kennard, 1950). Thus, nutrition and management experts began advising that 'The use of built-up litter makes it unnecessary to clean the house more than once a year' (Morrison, 1948). Yet flock sizes were smaller and growth rates for broilers were considerably slower than today’s standards so many issues with litter either did not exist or could be dealt with by hand. However, since current broiler strains grow rapidly, flock sizes continue to increase and labour costs have escalated, mechanical methods are required to deal with litter issues.

In the early days, producers pulled discs, harrows, weighted wire cattle panels, or old tyres tied together behind tractors to break up caked litter. Garden tillers were also used to reduce litter cake in preparation for the next flock. Yet these methods tended to leave larger chunks of hard, caked, high moisture litter with rough edges. It was difficult for baby chicks to manoeuvre over these chunks and older birds developed foot problems. In addition, the excess moisture increased ammonia concentrations in houses and, in turn, increased the need for ventilation, resulting in increased fuel usage.

Today, many producers own or have access to tractor-operated decaking machines to collect caked litter for spreading on fields or pastures. These units can do an excellent job and continue to serve the industry well. However, these units must be operated correctly to achieve the desired results and biosecurity is always a concern when several producers share any type of equipment. In addition, increasing environmental concerns and nutrient management plans of many farms now restrict or prohibit land application of litter, especially in sensitive watersheds.

An alternative litter preparation method that could satisfactorily prepare used litter without cake removal would have potential benefits to the industry in many areas across the country.

Evaluation of an Alternative Litter Treatment Method

Equipment Description

While standard decaking machines remove caked litter for spreading on pastures or fields, the Priefert Litter Saver (Priefert Ranch Equipment; Mount Pleasant, Texas; PLS) uses a series of curved hammers or teeth to break apart caked litter. When properly used, the PLS thoroughly mixes and aerates all the litter on the floor, allowing the once caked litter to remain the house and resulting in smooth, friable litter with little crust or hard pan at the pad surface.

Equipment Operation Principles

It is important to match PLS unit size (4’, 5’, or 7’) to tractor PTO horsepower rating to achieve proper performance. As litter depth increases over time, the horsepower demand required to properly operate the PLS also increases.

One pass of the PLS through the house is not enough to break up all the chunks of caked litter. We observed that three or four passes were necessary to obtain litter of the consistency and particle size desired. Initially, the litter treated with the PLS will be fluffier than litter in a decaked house but after a few days of baby chicks walking on the litter, this difference is no longer detectable.

Test Procedures

Flocks 92, 93 and 94 were placed on February 26th , May 15th and July 27th 2007, respectively, and were used to compare the effects that processing litter using the PLS or a decaking machine had on flock performance.

Inspection prior to the processing of litter revealed that approximately the same amount of caked litter was present in each house. Prior to flocks 92 and 93 litter in houses 1 and 3 were decaked, while cake in houses 2 and 4 were conditioned with the PLS. Prior to a third flock (flock 94), only the litter in house 3 was processed using the decaking machine and litter in the remaining houses was processed with the PLS.

The PLS was used to process all the litter in each treated house three or four times over a three-day period. Four loads of caked litter (about 7 tons per house) were removed from houses 1 and 3, prior to the placement of flocks 92 and 93, for a total of approximately 14 tons of caked litter per flock. Five loads (about 8.75 tons) were removed from house 3 prior to flock 94.

Test Results

Flock performance data obtained from the comparison of decaking with the PLS are shown in Table 1.

While the data presented slightly favour the PLS system over decaking, the few observations mean that such conclusions can only be tentative. However, in our situation we observed a savings in litter preparation time and fuel expense with the PLS. Yet the majority of this savings was due to hauling and spreading loads of caked litter on appropriate fields. If the Applied Broiler Research Farm (ABRF) had a litter stacking shed, time and fuel costs would likely have been similar.

In addition, if ABRF were selling litter as an income supplement, more litter might be present in PLS-treated houses. However, whether or not the PLS is a wise economic decision will depend upon the facilities and situation on the farm involved.

Observations and Precautions

It appears that the practice of reusing litter will remain the industry standard for the foreseeable future. Therefore, it will be necessary that each production unit have some strategy for processing litter prior to each flock. Since every farm and every farm manager is different, it is difficult to make overall recommendations. However, regardless of which litter processing system the unit uses, day-old chicks must not be placed on damp litter. Chicks placed on damp litter will be stressed and have reduced feed consumption, resulting in poor flock performance (Tabler, 2003).

Units are faced with a “pay me now or pay me later” choice with respect to litter processing. Skimping or short cutting litter processing will save house preparation time, but will provide a less than optimum environment for bird growth and the “pay me later” scenario may be seen in the form of a less than pleasing settlement check. The “pay me now” approach to litter processing will require extra time and effort prior to flock placement, but will likely pay dividends in the settlement check.

The approach to litter processing is entirely different when the PLS is compared to decaking. Decaking captures caked material from about the top six inches of litter and removes it from the house. The PLS pulverizes, mixes and aerates about the top 12 inches of litter into a soft, smooth, even surface. However, the PLS requires that litter be processed multiple times to achieve acceptable results. In this case, the PLS required that all the litter be processed three or four times to achieve satisfactory results. Both litter processing systems (decaking and the PLS) are only farm management tools.

Both the PLS and decaking machines can produce poultry house conditions that are good… or…bad.

The operator decides which environment the day-old chicks will face at placement.

| Table 1. Bird Performance Following Litter Preparation by Decaking or PLS | |||||||||

| FLOCK 92 (February 26, 2007 - April 20, 2007) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Litter Prep. Method | House Number | Livability (%) | Age (Days) | Avg. Wt. (Lbs.) | Net Sold (Lbs.) | Feed Conv. | Pay/lb. (cents) | Pay/house ($) | Gas Use (gals.) |

| Decaked | 1 | 96.90 | 53 | 6.90 | 118474 | 2.06 | 5.28 | 6248 | 1263 |

| PLS1 | 2 | 96.92 | 53 | 7.02 | 120430 | 1.99 | 5.63 | 6778 | 1134 |

| Decaked | 3 | 95.93 | 53 | 6.77 | 115006 | 1.98 | 5.57 | 6400 | 1114 |

| PLS | 4 | 96.78 | 53 | 5.74 | 115534 | 2.03 | 5.35 | 6178 | 1100 |

| FLOCK 93 (May 15, 2007 - July 10, 2007) | |||||||||

| Decaked | 1 | 96.56 | 56 | 7.60 | 127242 | 2.12 | 5.25 | 6676 | 376 |

| PLS | 2 | 96.23 | 56 | 7.52 | 125469 | 2.05 | 5.57 | 6934 | 375 |

| Decaked | 3 | 96.27 | 56 | 7.30 | 121880 | 2.02 | 5.63 | 6858 | 389 |

| PLS | 4 | 96.58 | 56 | 7.63 | 125413 | 2.05 | 5.54 | 6953 | 363 |

| FLOCK 94 (July 27, 2007 - September 24, 2007) | |||||||||

| PLS | 1 | 96.15 | 59 | 8.26 | 128770 | 2.11 | 5.27 | 6784 | 50 |

| PLS | 2 | 96.67 | 59 | 8.14 | 127497 | 2.07 | 5.43 | 6920 | 59 |

| Decaked | 3 | 96.20 | 59 | 8.23 | 128829 | 2.09 | 5.36 | 6910 | 72 |

| PLS | 4 | 96.47 | 59 | 8.17 | 129426 | 2.14 | 5.08 | 6571 | 68 |

| Average Data | |||||||||

| PLS | --- | 96.61 | 56.00 | 7.37 | 123961.50 | 2.06 | 5.43 | 6731.14 | 449.71 |

| Decaked | --- | 96.54 | 55.40 | 7.15 | 122391.80 | 2.06 | 5.37 | 6574.00 | 640.00 |

| 1PLS = Priefert Litter Saver (Preifert Ranch Equipment; Mt. Pleasant, TX) | |||||||||

|

|

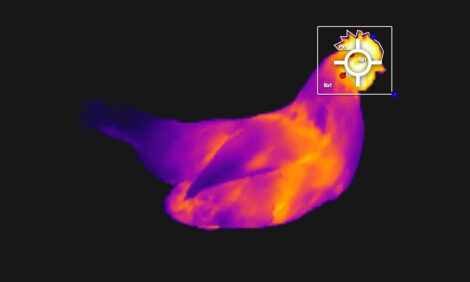

| BEFORE AND AFTER - The pictures above were taken in an ABRF house. The one on the left was taken before using the Priefert Litter Saver, and the photo on the right was taken after four passes with the machine. | |

Summary

Short down-times between flocks and increased concern for the environment have created a need for alternatives to removing and land applying caked litter after every flock of birds.

One such alternative was evaluated and no negative effects on flock performance were observed.

However, management is the key to successful litter preparation between flocks, regardless of the method used.

Skipping steps, cutting corners, and less-than-satisfactory conditions could prove costly to the next flock.

Investing the extra time and effort to do things right will likely pay dividends.

References

Ritz, C.W., B.D. Fairchild and M.P. Lacy. 2005. Litter Quality and Broiler Performance. Georgia Cooperative Extension Service Bulletin 1267.

Kennard, D.C. 1950. Floor litter management as a factor in poultry nutrition. World’s Poult. Sci. J. 6(3): 177-182

Morrison, F.B. 1948. Feeds and Feeding – A Handbook for the Student and Stockman. The Morrison Publishing Company, Ithaca, NY

Tabler, G.T. 2003. Early feed intake and bird performance. Avian Advice 5(1):13-15

Watkins, S.E. 2001. Litter conditioning for a healthy flock. Avian Advice 3(2):10-12.