LIVEgg: A data-driven hatchery

At IPPE 2019, we met with a lot of up and coming innovators in the tech industry, but LIVEgg stood out for its desire to improve performance - starting in the hatchery.Alon Blum, CEO of LIVEgg, was born in Israel where he has a wife and three children. With a background in industrial and management engineering, he has been in the poultry industry for 10 years. Before coming to LIVEgg, he worked in large poultry operations in Nigeria where he managed breeders, hatcheries and rearing houses. He also represented a number of satellite companies working in feed additives and vaccines and equipment for the poultry industry.

Bringing all this experience back home, he joined LIVEgg, an Israel-based bio-tech company founded in 2015 by Baram Group, a leading Israeli broiler breeding, semi-integration and bio-medical engineering firm.

CrystalEgg: A hatchery that responds to what the embryo needs

Already on the market, CrystalEgg is a technology which seeks to improve not only the quantity, but the quality of chicks that leave hatcheries.

“The problem is that once you put the eggs inside the incubators, we’re only able to observe the environment around the egg – the humidity and temperature - but nothing inside the of it,” explains Alon.

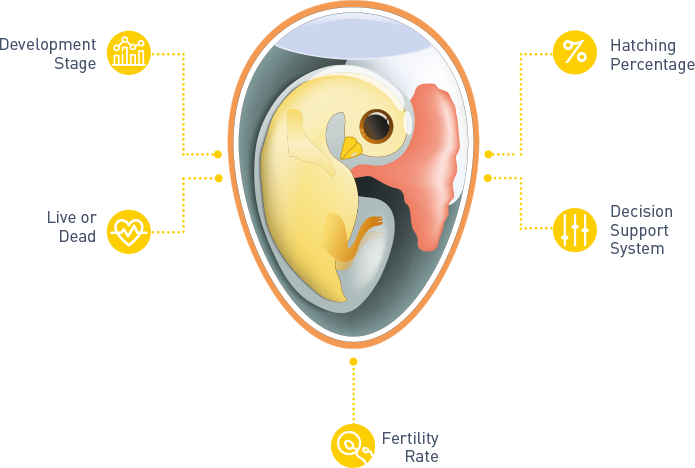

“So CrystalEgg is actually monitoring the embryos’ development stage and gives a very clear observation about that.”

What CrystalEgg does, Alon explains, is monitors eggs to check which are fertile and infertile, which are alive or dead and, if there is a mortality, at what time the mortality occurred. With this information, hatcheries can give feedback to breeders about such issues as early mortality or fertility drop – an issue which is normally referred to the breeder level rather than the hatchery.

This early feedback is in contrast to the 21-day cycle, at the end of which a problem is observed but the hatchery may not be aware as to what that problem actually is, so they do another cycle. “Now, we’re already one and a half months later and only then, if you have a very good staff, will they tell the breeding manager that they have a problem.

“With CrystalEgg, after 7 days the system will send an alert by itself to the poultry manager,” explains Alon.

Another issue the CrystalEgg system seeks to resolve is uncertainty around actual hatch numbers. By the seventh day of the cycle, Alon says that CrystalEgg is able to accurately predict exactly how many chicks will hatch, so that hatcheries can more effectively and efficiently plan their sales and logistics, such as if there is more than one hatchery and they need to combine trucks and transportation to meet demand.

“After seven days, [the hatcher] knows how many chicks there will be and still has two weeks to plan everything.

“Then at the upper level, we monitor the development of the embryos, and we know how to connect between the environmental conditions and the development of the embryo inside the eggs,” Alon goes on.

In so doing the incubation conditions can be perfected according to what the embryos need, which leads to better optimisation of the incubation process. One of the main advantages to this is that the hatch window is made shorter, so more chicks result from the same amount of eggs - and with better quality and uniformity to boot, owing to conditions which respond to the specific needs of the embryos in the hatchery.

The question of cost is raised, but owing to CrystalEgg’s processing capabilities, only 400 of 60,000 eggs, for example, need be placed into the smart tray systems which, according to Alon, yields an accuracy of 99.5 percent.

“Our vision is to connect our system to the hatcheries’ controllers, so that the embryos will manage the hatch protocol, rather than using fixed protocols; then you will have a completely automated hatchery.”

Alon explains that their CrystalEgg technology has already been installed in several places around the globe.

LivEgg’s mission to end male-chick culling

Another product which is in the final stages of development is LivEgg’s in-ovo sexing technology, ChickMale Saver.

It’s claim-to-fame is that it is non-invasive. “We are using the same technology [as CrystalEgg], but we are doing in-ovo sexing. It will be ready for sales in early 2020. It will actually work like a candling machine. It will not be on the trays like this,” Alon gestures towards the CrystalEgg trays, “it will be on a candling machine that, instead of taking out only the infertile eggs, it will separate between male and female embryos.

“Depending on the segment, if we are talking about layers, it will take out the eggs. If it’s a broiler or breeder, it will just separate between them so each one of them will hatch differently. We can even combine between the two products later, because if we separate between male and female, by using the CrystalEgg, we develop a way for us to give each of them a different protocol of incubation.”

What sets ChickMale Saver apart from other breakout technologies is that it identifies sex without getting anything inside the egg and the test itself doesn’t cost anything. “Once you have the system, you have the test” unlike polymerase chain reaction (PCR) tests which cost money, explains Alon.

Why it matters

The other benefit to LIVEgg sexing technology is that it’s efficient. Compared to the PCR method which is limited in number of eggs per hour, ChickMale Saver can reach about 50,000 eggs per hour.

Their in-ovo sexing technology uses algorithms combined with machine learning methods. Once it identifies whether it’s a male or female egg, it will be exactly like a normal candling machine, says Alon.

“The egg will come, there will be some kind of device that will look at the egg, will check out those parameters using our technology, and analyse it very quickly. We are talking about an analysis that will take about 5 seconds, and then continue.

“And when it continues, since we know whether it’s male or female, vacuum arms will come and take only the male eggs, and as I said before, either throw them away, or separate between the female and male.”

Such technology has big implications for the industry, not only in terms of driving efficiencies but in terms of animal welfare – as today about 5 billion male chicks are being culled on the day of hatch. The big integrators investing in animal welfare understand it is not only something that consumers care about, but that it’s important too.

“Eggs are sexed at about the seventh day,” explains Alon. “We do it earlier than 10 days at least because there is not much development of the embryo, so you can just take out the eggs without harm.”

This technology also benefits the broiler industry, Alon adds, since growing the males and females in different houses appears to be more efficient for the industry and for farmers. In fact, the breeders benefit as well, since the males and females need to be sexed and separated, and in-ovo sexing can go a long way to making that process more efficient, he says.

Big data for a big industry

The last product in LIVEgg’s portfolio is that of data solutions and insight. Seeking to share their knowledge, they aim to provide insight by means of a system which uses proprietary algorithms connected to the global industry to help users make better, data-driven decisions based on an understanding of trends in the industry.

If an organisation wants to make money, it will need to be even more efficient, and today, this is the only way to do it. To manage data, to combine all kinds of system together, sort it, analyse it and present it in a way that will really make the management of the operation efficient and to have insights with which one can make decisions.

“We’re developing our data management all the time with many companies. We optimise it and give solutions for all kinds of data management needs.

“This is us.”