Minimising Wet Litter Problems During Hot Weather

It is crucial that broiler producers understand the impacts that evaporative cooling and airspeed in order to maintain litter conditions in hot weather, according to Michael Czarick (Extension Engineer) and Brian Fairchild (Extension Poultry Scientist) at the University of Georgia.Managing proper litter moisture during cold weather with low outside air temperatures, loose houses, low air exchange rates and high fuel prices has been and always will be a challenge. But, many producers are now finding maintaining good litter quality during hot weather can be equally as challenging, even in the best of housing.

One of the primary reasons why it is becoming more difficult to control litter moisture during hot weather is the trend towards growing larger and larger birds. Larger/older broilers require lower house temperatures toward the end of the flock in order to keep them comfortable. Whereas a target temperature the last week of a flock for some growing a four-pound broiler may be around 75°F, for someone growing a seven- or eight-pound bird, the target temperature the last week of the flock will be 10 or more degrees lower. The lower target temperatures will inevitably result in an increased need for evaporative cooling pads to maintain desired house temperatures during hot weather.

Furthermore, since the birds are in the house longer, instead of pads systems being used for a week or two during a summertime flock, producers growing large broilers may need to use their pads systems on a daily basis for nearly a month increasing the likelihood of litter moisture problems.

It comes down to the simple fact that the more a producer uses their evaporative cooling system, the more of a challenge it will be to maintain proper litter conditions.

It is very important to keep in mind that evaporative cooling is not “air conditioning”. An air conditioning system reduces the temperature AND the relative humidity of the air. The more you use it, the lower your temperature and humidity will be in a house.

As the name implies “evaporative cooling” pads reduce the temperature of the incoming air through the evaporation of water into the air. As a result, cooling comes at a price - increased humidity. For every one degree cooling, the relative humidity of the air will increase approximately 2.5 per cent. For example, when the outside air temperature is 90°F and the relative humidity is 55 per cent (hot, humid weather) the typical pad system will decrease the incoming air temperature approximately 10°F, which in turn will increase the relative humidity of the air to 80 per cent.

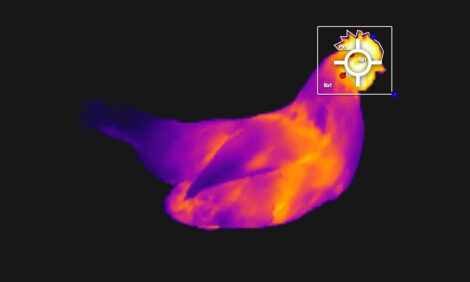

The end result when using evaporative cooling during hot, humid weather is that the relative humidity in a house will typically run between 75 per cent and 90 per cent, making it very difficult to keep litter dry (Figure 2).

Using evaporative cooling when outside temperatures are below 82°F will also contribute to litter moisture problems.

During the summertime, outside temperature and relative humidity tend to cross over at 80°F and 80 per cent humidity. That is, when the outside temperature is above 80°F, the relative humidity will be below 80 per cent and evaporative cooling systems can generally be used without resulting in excessive house humidity.

However, when the outside temperature is below 80°F, the relative humidity will tend to be above 80 per cent and as a result, evaporative cooling pads will produce a very limited amount of cooling and tend to push the relative humidity of the incoming air to near saturation making it next to impossible to keep litter dry.

To minimise wet litter problems, ideally, evaporative cooling pads would be set to operate closer to 85°F than 80°F.

In Figure 3, the pads in the house were set to operate at 80°F, i.e. they turn off at 78°F. The relatively low pad operating set point resulted in the humidity of the incoming air to run between 85 and 90 per cent during the day. Had the pads been set at 84°F, pad operation would have been reduced, thereby making it slightly easier to control litter moisture.

Being able to operate pads at a slightly higher set temperature depends to a large extent on the wind speed in a house. The higher the wind speed, the greater the cooling effect, the lower the need for evaporative cooling. For instance, if a house with 600 feet per minute air speed will produce substantially more bird cooling than one with 500 feet per minute, thereby making it much easier to delay the use of evaporative cooling pads without harming bird performance.

Bird migration is another contributor to summertime litter moisture problems (Figure 4).

In order to keep litter dry, especially with humid air, there needs to be a high level of air movement over the litter. The more humid the air, the greater the amount of air flow over the litter required to keep it relatively dry. When densities are very high due to bird migration, the amount of air movement over the litter is negligible. This is one reason why litter tends to be drier on the tunnel fan end of a house during hot weather where bird density is typically lower (Figure 5).

|

|

|

Figure 4. High bird densities can make it very difficult to control litter moisture.

|

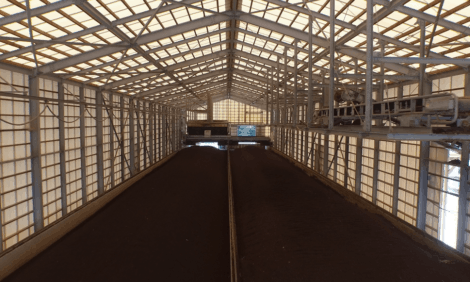

Figure 5. Lower bird densities on the tunnel fan end of a house increase air movement over the litter leading to fewer moisture problems.

|

Insufficient air movement over the litter can be a problem throughout a house when producers do not operate a sufficient number of fans when using their evaporative cooling pads.

Because the relative humidity of the air will tend to be very high when using evaporative cooling pads, it is important that air movement/exchange is maximised to ensure that adequate moisture is pulled from the litter. The more humid the air is in a house, the greater amount of air movement/exchange is required to keep the litter dry. It is not that different from trying to clean up a spill with a damp paper towel. The damper the paper towel, the more you have to move the towel over the spill to soak up the water and the greater the number of towels that will be required. As a result, with older birds (last two weeks of the flock), it is best to use all the house's fans before using the evaporative cooling.

With younger birds when all the houses, fans are not generally required to keep the birds comfortable, the cooling produced by a pad system should be limited through the use of a timer. For instance, when birds are two to three weeks old, pads should be operated in a way to temper the incoming air. Instead of the pad system operating constantly and dropping the house incoming air temperature to the low 80s with a humidity of over 80 per cent, it is often better to operate the pads on an interval timer - less than a minute out of five minutes - so that the incoming air temperature is only decreased to the mid to high 80s. The reduction in use of evaporative cooling will result in a house humidity possibly in the 60 to 70 per cent range, which will make it easier to control litter moisture.

An area of a house where air movement tends to be relatively low and as a result especially prone to litter moisture problems is at the tunnel inlet end of a house. It is often thought that litter caking in this area is caused by the proximity of the evaporative cooling pads and as a result the air is much more humid here than in other areas of the house.

The fact is that the variation in relative humidity in a house when tunnel ventilating typically is less than 10 per cent from the pad to the fan end of a house. It is the low level of air movement in this area of the house that is the real culprit.

Have you ever noticed that though the litter caking tends to be higher in the inlet area, it often quickly disappears just past the end of the pads where air velocity picks up? The air velocity in the pad area is typically less than 300 feet per minute and increases to 500 to 700 feet per minute just past the end of the evaporative cooling pads and as a result, the litter tends to be slightly drier.

Though it will not totally solve the problem of wet litter, tunnel doors have proven to help reduce litter caking in the tunnel inlet end of a house by increasing the amount of air movement over the litter (Figure 6).

Last but not least, the use of interior fogging nozzles on hot, humid days is a significant contributor to litter moisture problems during hot weather. It is important to realise that interior fogging nozzles will do little cooling in a house when the relative humidity is much above 80 per cent, which from the graphs above you can see is fairly typical in a house using evaporative cooling pads.

As a result, most of the water added to a house by a fogging system tends not to evaporate leading to wet birds and floors.

Worse yet, the moisture added to the house by the fogging nozzles tends to wet fan shutters, increasing the likelihood that dust will collect on the shutters, reducing the air moving capacity of the fans and in turn bird cooling. This is not to say that interior fogging nozzles should never be used. If the house temperature climbs above the mid- to high-80s, the relative humidity of the air in the house will tend to be below 80 per cent and therefore the limited use of interior fogging nozzles is generally advised.

In order to maintain litter conditions in hot weather, it is crucial that producers understand the impact that evaporative cooling and air-speed can have on floors. Using the information above, producers can operate evaporative cooling during optimum periods when the temperature is high enough that the relative humidity will not result in wet floors.

The drier floors will, in turn, provide better environment for the birds and reduce caking that will result in less clean-out effort for producers.

August 2013