Poultry Waste: Georgia's 50 Million Dollar Forgotten Crop

By Larry Vest and Bill Merka, Extension Poultry Scientists & William I. Segars, Extension Agronomist, The University of Georgia - The value of manure as a source of plant nutrients has been recognized for centuries. Poultry manure contains all essential nutrients required for crop production. In spite of its beneficial effects on plant growth, manure constitutes only a very small percentage of nutrients applied to cropland when compared to commercial fertilizer.There are several reasons why poultry manure is not used to its fullest potential. Among these are: (a) lack of information on the value of manure as a source of plant nutrients (b) failure to recognize how and where to utilize it; and (c) lack of recognition of its economic value.

Quantity of Poultry Waste Generated

This publication summarizes the information presently available which promotes the better use of this by-product of the poultry industry.

This publication summarizes the information presently available which promotes the better use of this by-product of the poultry industry.

Growth of Georgia's poultry industry has produced large quantities of poultry manure and used litter. In 1992, Georgia's poultry population was estimated at 1 billion broilers; 12 million commercial laying hens; 11.8 million broiler breeder hens; 12 million replacement pullets (both light and heavy) and 2.4 million turkeys. These birds produced a valuable by-product, poultry manure, with a potential gross value of over 50 million dollars.

For each pound of feed consumed, a chicken or turkey will produce approximately 1 pound of fresh manure with a moisture content of about 75 percent. Once voided from the bird, the manure will rapidly loose water until the final product has a moisture content of 20 to 40 percent. The final moisture content will vary depending on type and quantity of bedding, bird concentration, watering equipment and ventilation system.

Good estimates of annual manure production are: 2.5 pounds of manure per broiler, 40 pounds per commercial layer, 44 pounds per broiler breeder, 8 pounds per replacement pullet and 31 pounds per turkey.

Composition of Poultry Waste

Semi-Solid and Solid Form

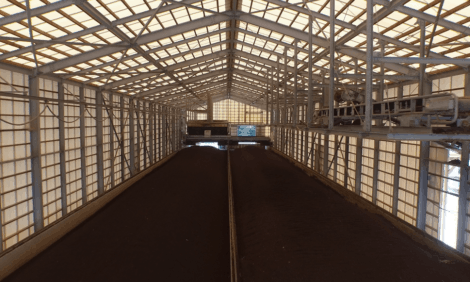

Poultry manure consists primarily of droppings and bedding (usually wood shavings or sawdust) with varying moisture content. Feathers and waste feed make up the remainder except in dirt floor houses where soil may be mixed in. Hen manure may or may not contain bedding materials.

Average plant nutrient content of poultry manure is listed in Tables 1 thru 4. Poultry litter and manure vary in both physical and chemical composition. Factors affecting composition include: type of birds raised, number of birds per unit area, nutrient density of the feed, type and amount of bedding material, time in use and other management factors. Environmental factors during production, storage and methods of handling after production also influence poultry manure composition.

Frequently it will be necessary to stockpile the poultry manure when the producers clean out their facilities. Place the manure in a structure that will prevent surface or groundwater contamination. Generally, the stockpiled litter will go through some degree of composting. Therefore, the level of certain plant nutrients will be changed, especially nitrogen (Tables 1, 3 and 4). Based on the average plant nutrient levels (Table 1), a ton of poultry manure has an estimated value of $26.00 (Table 5). A 20,000 bird broiler house will produce approximately 140 tons of manure per year (6 flocks) with a potential gross value of $4,000. A flock of 14,000 breeder hens will produce approximately 308 tons of manure in one year with a potential gross value of nearly $6,314.

The cost of transporting poultry manure can vary from location to location. Manure removed from a broiler house is usually very bulky (20 to 25 pounds per cubic foot); thus, increasing its transportation cost per pound of nutrient. The cost of transporting a ton of broiler manure ranges from $8 to $14 per ton. The average delivered cost per ton of broiler litter by commercial operators is $20.

An economic evaluation of poultry manure as a fertilizer should be made with actual costs figures and actual nutrient analysis. Also, consider the value of adding organic material to the soil.

| Table 1. Average Amount of Plant Nutrients in Broiler and Hen Manure on an As-Is Basis | ||||

| Manure Type | Total N | Ammonium NH4 | Phosphorus P2O5 | Potassium K2O |

| lb/ton | ||||

| Broiler house litter1 | 66 | 10 | 50 | 40 |

| Roaster house litter1 | 68 | 11 | 53 | 41 |

| Breeder house litter2 | 31 | 7 | 40 | 35 |

| Stockpiled litter | 36 | 8 | 55 | 35 |

| 1Assumes a moisture content of 23%; 2Assumes a moisture content of 40%. | ||||

| Table 2. Average Nutrient Composition of Layer Manures | ||||

| Manure Type | Total N | Ammonium NH4-N | Phosphorus P2O5 | Potassium K2O |

| lb/ton | ||||

| Undercage scraped1 | 28 | 14 | 31 | 20 |

| Highrise stored2 | 38 | 18 | 56 | 30 |

| lb/1,000 gallons | ||||

| Liquid slurry3 | 62 | 42 | 59 | 37 |

| Anaerobic lagoon sludge | 26 | 8 | 92 | 13 |

| lb/acre-inch | ||||

| Anaerobic lagoon sludge | 179 | 154 | 46 | 266 |

| 1Manure collected within two days 2Annual manure accumulation 3Six-12 months' accumulation of manure, excess water usage and storage-surface rainfall surplus; does not include fresh water for flushing. |

||||

| Source: Biological and Agricultural Engineering Department, NCSU. | ||||

| Table 3. Average Nutrient Composition of Turkey Manures | ||||

| Manure Type | Total N | Ammonium NH4-N | Phosphorus P2O5 | Potassium K2O |

| lb/ton | ||||

| Brooder house litter1 | 45 | 9 | 52 | 32 |

| Grower house litter2 | 57 | 16 | 72 | 40 |

| Stockpiled litter3 | 36 | 8 | 72 | 33 |

| 1Based on cleanout after each flock. 2Based on annual cleanout after full production. 3Based on annual house accumulation removed to uncovered stockpile to be spread within six months. |

||||

| Source:Biological and Agricultural Engineering Department, NCSU. | ||||

| Table 4. Average Secondary and Micronutrient Content of Poultry Manures | ||||||||

| Manure Type | Ca | Mg | S | Na | Fe | Mn | Zn | Cu |

| lb/ton | ||||||||

| Layer | ||||||||

| Undercage scraped | 43 | 6 | 7 | 4 | 0.5 | 0.3 | .3 | Trace |

| Highrise stored | 86 | 6 | 9 | 5 | 1.8 | 0.5 | .4 | Trace |

| Broiler Litter | ||||||||

| Broiler house | 43 | 9 | 15 | 13 | 3.8 | 0.8 | .6 | .4 |

| Roaster house | 47 | 10 | 14 | 13 | 4.0 | 0.8 | .7 | .6 |

| Breeder house | 120 | 11 | 8 | 9 | 9.4 | 1.6 | 1.0 | .4 |

| Stockpiled | 54 | 10 | 12 | 12 | 3.9 | 0.8 | .7 | .6 |

| Turkey Litter | ||||||||

| Brooder house | 28 | 6 | 7 | 6 | 1.4 | 0.5 | .5 | .4 |

| Grower house | 42 | 7 | 10 | 8 | 1.3 | 0.6 | .6 | .5 |

| Stockpiled | 42 | 7 | 9 | 6 | 1.5 | 0.6 | .6 | .3 |

| lb/1,000 gallons | ||||||||

| Layer | ||||||||

| Liquid slurry | 35 | 7 | 8 | 5 | 2.9 | 0.4 | 0.43 | 0.080 |

| Lagoon sludge | 71 | 7 | 12 | 4 | 2.2 | 2.3 | 0.80 | 0.14 |

| Boron - Approximately 20 grams per ton or 25 grams per 1000 gallons. | ||||||||

| Table 5. Value of Fertilizer Elements in One Ton of Broiler and Hen Manure | ||

| Plant Nutrient & Value per Pound | Broiler ($/ton)1 | Hen ($/ton)1 |

| Nitrogen - $0.25 | 9.75 | 4.65 |

| Phosphate - 0.28 | 11.20 | 8.96 |

| Potash - 0.12 | 3.84 | 3.36 |

| Calcium - 0.03 | 1.42 | 3.60 |

| Total | $26.21 | $20.57 |

| 1Assumes the following efficiency factors relative to commercial fertilizers: Nitrogen-60%, Phosphate-80%, Potash-80% For a cropping season when manure is soil incorporated. |

||

| Note:Only 50% of N is available if surface applied to pastures. | ||

Liquid

Liquid manures from laying hen operations with flush systems may be stored in concrete or steel storage tanks or in lagoons. In either case, the storage facility should be adequate to store the manure until it is used.

A lagoon is not considered a convenient method of waste disposal but rather one treatment process in the overall waste management plan. Lagoons are biological digesters in which bacteria decompose organic matter into gases, liquids and sludge. There are two types of lagoon systems: 1. anaerobic, and 2. aerobic. Nutrient values for anaerobic lagoon liquid and sludge are given in Tables 2 and 4.

Nutrient Quality

The nutrient quality of broiler litter has been improved by the move toward multiple flocks. It is now customary to produce four to six flocks per year with an annual clean-out of the house. The nutrient content increases from 5 to 15 percent when the management system was changed from one to four flocks per clean-out.

In addition to being an excellent source of plant nutrients, poultry manure can increase the water infiltration rates of soils by improving the soil structure. On a short term basis, poultry manure can also increase the soil organic matter content.

To obtain maximum nutritive value, incorporate manure into the soil immediately after spreading. First year nitrogen availability coefficients for different poultry manures are shown in Table 6. For optimum utilization, manure should be used to meet as much of the phosphorus and nitrogen needs of the crops as possible. Use commercial fertilizer to furnish other nutrients to the levels needed as indicated by soil tests.

Ammonia production begins upon adding manure to a warm, moist soil. Maximum levels of ammonia occur during the first two weeks. Nitrate production usually is slow during the first week and gradually increases until about the fourth week when it reaches a maximum rate of production; maximum levels of nitrate usually occur at this time if no leaching has occurred. Research shows that 30 to 60 percent of the total nitrogen comes available during the first six weeks, depending upon the nitrogen content of the manure and the form in which it is present. The ratio of carbon to nitrogen is also important. High carbon litters such as sawdust may materially retard nitrate accumulations. The remaining nitrogen will be released very slowly during the process of decom-position of the organic residues. This release may require considerably more than one season.

A study of the rate at which carbon dioxide is evolved from manure mixed with soil also confirms the fact that most of the microbial activity probably occurs during the first two weeks. During this period of time take care to prevent damage to plants either by an under or over supply of nitrogen. With poultry manure, it is usually the latter. Occasionally some poultry manures contain so little nitrogen that decomposition of the manure uses nitrogen present in the soil.

Phosphorus, except for small quantities in the urates, is in the organic form in chicken manure. Availability of phosphorus, therefore, is directly related to the rate at which the manure decomposes. This element becomes available much slower than nitrogen because it's easily bound by elements in the soil. Most potassium in living tissue is believed to be in ionic form and is moderately retained. Upon death of the cell, the potassium is no longer retained and is easily leached from the tissue. Potassium in chicken manure is present as an inorganic salt in the excretions from the kidneys and in the living and dead cellular material in the feces. All forms of potassium in manure are quite readily available to plants in most cases, but may be rapidly lost by leaching.

Many other elements are present in chicken manure in very small quantities (Table 4). Little is known concerning the rate of release of these elements, but essentially all become available in the course of decomposition.

Application of Poultry Waste

Poultry manure can be successfully used on many crops. General rates and times of applications are listed in Table 7. A successful manure utilization program includes the following: 1) soil test, 2) crop nutrient requirements, 3) manure nutrient values and 4) proper storage and application. To prevent excess application of poultry manure and the potential contamination of surface and ground water, prepare a nutrient budget worksheet for each field or crop.

The figures given in Tables 1 and 4 are average values. The actual nutrient profile of a particular manure sample may vary greatly from the averages. Therefore, analyze the manure you plan to use for its true plant nutrient content. Also, before using poultry manure, check with your county extension agent about a soil test. Armed with this information, you and your county agent can decide on the best plan of action to utilize part of Georgia's 55 million dollar forgotten crop.

Example: Land Application

Farmer Jones is preparing to spread broiler litter on a field and incorporate it within two days to supply nutrients to his corn crop. Last year, he grew soybeans in his field.

His corn-yield goal is 140 bushels per acre, and he has decided to apply the eqivalent of 140 pounds of nitrogen per acre. His land is not suject to erosion, is not a nutrient sensitive watershed, and has grassed borders and waterways to further prevent run-off.

Farmer Jones used a starter fertilizer on his corn crop at a rate to supply ten pounds of nitrogen per acre. He intends to supply the rest of his nitrogen needs by applying broiler litter with a litter spreader and incorporating it within 2 days.

How much litter does he need to spread in order to meet the needs of his nitrogen crop? Will he need to supplement the crop with additional potash or phosphate to satisfy his soil-test recommendations of 50 pounds per acre of each nutrient. The answers are given in the worksheet.

To read the nitrogen worksheet, please click here

Poultry Litter as a Livestock Feed

Poultry manure can also be used as a feed ingredient for cattle. When used properly, poultry litter can be an excellent source of supplemental protein, calcium, phosphorus, and roughage. Poultry litter is not a good source of energy for cattle. The total Digestible Nutrients (TDN) found in broiler litter indicates a relatvely low-energy feed. Calculated TDN values range from 25 to 60 percent.

Select only good quality litter for processing. The litter should be free of rocks, glass, metal and other foreign objects. The litter taken directly out of the house will usually have 20 to 25 percent moisture which is adequate for the ensiling process and storage. Deep stacking under a shed or outside (covered with heavy plastic) is the method most often used. Allow 4 to 6 weeks for ensiling before feeding.

Research shows that a mixture of 80 percent litter and 20 percent grain (mainly corn) is the best for beef brood cows. They can be fed 75-80 percent of their requirement from this type mixture. The other 20-25 percent should be some type of good roughage (coastal hay, fescue hay, fescue pasture, etc.). For growing stocker cattle, a mixture of 50 percent litter and 50 percent grain is suggested to be used with good quality roughage. Vitamin A (3.5 million units) should be added to each ton of litter and grain mixture. For more detailed information consult your county Extension agent and or Animal Science leaflet #406 entitled Use of Alternative Feeds for Beef Cattle.

Source: The University of Georgia - Georgia College of Agricultural & Environmental Sciences Cooperative Extension Service - July 2004