Productivity Improvements - The Betagro Way

Vanus Taepaisitphongse is CEO of the Betagro group, a major force in the Thai livestock and food industries. Speaking at the 2009 Asian Livestock Feed and Meat Industry Conference, he gave a fascinating insight into the benefits to Betagro of detailed analyses of the company's working practices, writes Stuart Lumb for ThePoultrySite.

Betagro has joint-ventures with six different Japanese companies, which generally involve producing top quality cooked pork and poultry products which are shipped to Japan.

In 2000, Betagro used Kaizen (Japanese for "continuous improvement") concepts to improve productivity in the company's plants.

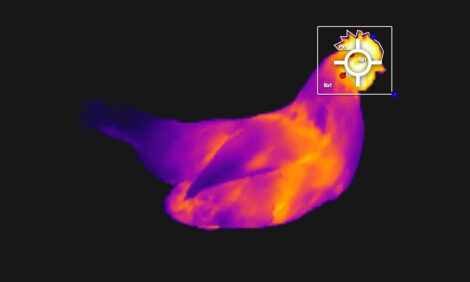

One analysis is related to a special cutting process.

Through the use of video analysis, the cutting process was rejigged, resulting in a 39 per cent reduction in operator body movements.

Unfortunately, these productivity improvements did not always result in financial benefits and so Betagro moved on to "Total Productivity Improvement".

One example involved analysing poultry breeding operations, right through from the production of parent stock to the slaughter of broilers.

Feed manufacture and feed handling were also assessed.

Betagro had planned on increasing the size of its poultry operation to increase output. However, after the analysis was carried out the improvements when implemented resulted in improved output from the existing plants/operations. Consequently, there was no need to spend money increasing the size of the operation.

Yakitori is a type of Japanese chicken kebab which Betagro produces, with the product line being staffed with groups of 10 workers.

Skill levels and work rates of all the workers were assessed and turned out to be quite varied. Productivity was determined by the slowest workers and the supervisors had to help these slower workers in order to maintain satisfactory production levels on the line.

Following these assessments, all the workers were graded by their work rate, from fast through to slow. New teams were put together so that all the workers in each team had the same work rate, ranging from fast through medium to slow. This new concept was implemented and resulted in massive savings for the company.

Betagro has its own feedmills and significant savings have been made there.

The automatic bagging of feed had never been checked properly and it was found that the feed flow into the bagging lines was not smooth. Once corrected packing losses were reduced from 40g per bag to just 6g.

In one year, savings in just one mill amounted to between 1 and 2 million baht (THB) and for all mills, a very significant THB7.2 million.

In another example, the re-engineering of pelleting plants resulted in a saving of THB8 million.

Mr Vanus concluded by telling the audience: "Many ideas are coming through the company but from the bottom up."

This is heartening as Betagro is obviously encouraging its staff to make suggestions regarding improving efficiency and they are responding positively.

From Our Farm To Your Table Eddy Ng and his daughter.

Mr Ng has runs a 550-sow pig unit near Kuala Lumpur. His sows are LW × LR F1 crosses inseminated with Duroc semen giving a slaughter pig with 50 per cent Duroc genes. The Duroc breed is noted for eating quality and it is no coincidence that Mr Ng likes this breed because he sells his own pork through his own butcher's shop in downtown Kuala Lumpur. His shop doubles as a restaurant and his clientele like the fact that they know where the pork comes from. "We have only been up and running for four months but all's going well," said Mr Ng. "I'm very proud of the fact that my business has HACCP certification, plus I am the first and only business in Malaysia to have achieved ISO 22000 status and so am Quality Assured." The indiscriminate feeding of antibiotics to pigs has caused many affluent Malaysians with higher disposable incomes to eat other meat. Mr Ng's operation is 100 per cent transparent and so his customers can feel comfortable about eating and buying his pork. Looking at the shop section much of the pork on sale appears unusual to Western eyes – heart, stomach, tails, feet and the like. What in the West is classed as offal is a delicacy in Asia, hence a growing trade in offal exports from Europe to Asia. Mr Ng is helped in the restaurant and shop by other members of his family, which is all good experience for them as he wants to open several more restaurants. |

December 2009