San Miguel Transforms Farm Management, Products into Future Success

San Miguel believes that every quality product, its goodness and wholesomeness, starts right at the farm. Every dressed chicken that makes its way from the farm to the various fresh markets, retail outlets, branded Magnolia Chicken Stations and into the home carries with it the whole process that makes the product live up to its promise to the consumer.

San Miguel, established in 1890 as a brewery is now one of South-east Asia's largest publicly listed food, beverage and packaging companies with 15,000 employees in over 90 major facilities throughout the Asia-Pacific. Its foundation of closely related businesses enjoy major positions in each market segment and export to 60 markets around the world. The company has an important tradition of product quality which it exploits in its food and agribusiness group, namely San Miguel Pure Foods Co (SMPFC), to create and develop poultry products which are attracting a growing consumer base in domestic and export markets.

According to vice president, Rita Imelda Palabyab, of SMFI-Poultry, there is really no secret in raising chicken, yet among the major industry integrators the company provides a distinct effort across all the phases of getting a product from the farm to becoming a popular, growing product choice for consumers.

SMFI-Poultry start with the best feed, the top breed and continue with the most efficient processing utilising the latest technology, research and development down to innovative distribution and product presentation to the market.

A priority is the thriving outsourcing model for growers, which has been running for more than 40 years and covers all of the 1,300 contract farms nationwide.

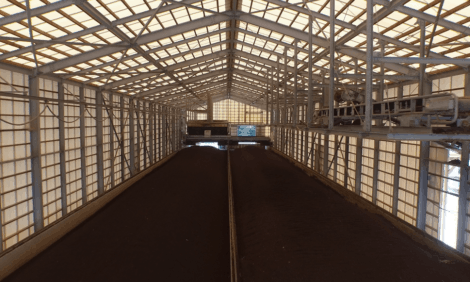

“We have the most widespread and successful application of third party arrangements for the broiler growers which has a history from around the late 70’s," says Mrs Palabyab. "The stability provided by this programme based on high quality feed and day-old chicks, supported strongly with technical service, house design and other farm services, assures growers of good performance."

SMFI-Poultry national contract growing manager, Enrico Zavalla, heads up the growing unit and is tasked – along with the farmers – of delivering the right sized chicken in the right quantity to the different segments of the market.

"Getting it right starts with the grandparent stock received as day-old chicks with the required traits that come from the breeding company, the parent stock produced from these birds which are delivered to dedicated farms where they in turn produce broiler eggs, which are hatched and placed on contract grower farms all over the country," says Mr Zavalla.

"These growers are then intensively supported by broiler production representatives and broiler technical specialists who work together with the growers in making sure the house environment, systems for feed and water and general management skills for the correct technical procedures when vaccinating, sample weighing or just maintaining the right environmental conditions are all part of the joint target of forecasting accurate bird weights and determining when each flock is ready for depletion," he added.

In addition to technical support, SMFI-Poultry assists growers in working with financial organisations to ensure funding is in place. They use poultry house innovations like plastic poultry house slats produced by a sister company from the San Miguel Group, partnering with a national gas supplier to ensure that efficient, affordable heating is used in production, clearly demonstrating financial return and supporting the introduction of controlled climate systems or tunnel ventilation in raising modern broilers efficiently.

The extensive support has improved growth rates, maximised the number of broiler flocks a grower can raise annually and optimized their capacity and profitability &ndash all important ingredients in the continued success of the poultry company.

The early intensive technical and operation support management that goes into growing a quality product is enhanced by the modern processing facilities required to produce a wide range of fresh products for the consumer. Processing then turns into a range of options including flexible ordering systems, online sales options and customised products, which work together to deliver the final products the customer desires.

SMFI’s poultry business is allowing consumers more opportunity to exercise their choice in choosing a product and the quantity they prefer. Market research has assisted in helping the company decide on the Magnolia Chicken Station – a concept inspired by the traditional wet market ‘tingi’ system where chicken parts are laid out and consumers select the exact quantity and number of parts required.

Magnolia gave it new life by branding the products, conveying quality, hygiene and freshness and presenting a wider variety of chicken cuts than normally available.

* "Although the demands are more than usual, being an exporter to Japan’s premium market is attractive business for San Miguel" |

Consumers have responded with tongs in one hand and a plastic bag in the other, selecting their favourite chicken part in spicy, seasoned, marinated or just unflavoured fresh form, growing the business dramatically each year. Quality, convenience and variety have combined along with placement in major supermarkets nationwide to grow Magnolia chicken to an estimated 40 per cent of the market and place it firmly in the minds of consumers.

The reputation for value-added, customised products has assisted SMFI-Poultry in winning approval to export to Japan, a market renown for its rigorous quality and product specification standards. While exporting a range of products to Japan, the major product comprises of skewered, succulent chicken pieces dipped in barbeque sauce and grilled and served at yakitori restaurants.

Meeting the requirements of Japanese importers is challenging. Mrs Palabyab describes how each yakitori stick is made. "If they ask for a 50 gram yakitori chicken it cannot be 49 or 51 grams, it has to be 50 grams. It also should be skewered in such a way that the stick doesn’t show between the chicken pieces and there should be a 0.5 centimetre allowance at the tip so that it fits their griller perfectly."

SMFI-Poultry has developed a dedicated team at two processing plants within the Philippines to meet the requirements and produce the yakitori sticks at up to 100 sticks per hour. "Although the demands are more than usual, being an exporter to Japan’s premium market is attractive business for San Miguel”, adds Mrs Palabyab.

Many markets prefer locally branded products over imported counterparts. San Miguel offers private label options, also known as in-house or store brands, to carry the name of an individual or business. It is a solution to clients who wish to partner with San Miguel yet provide the specific requirements they consider important to their businesses.

The task of marketing and selling these products is in the hands of the client company and San Miguel can complement this advantage with competitive pricing and quality. Private label business is strategically important to overseas expansion and enables the company to become further acquainted with markets and in good position if at some time its own branded product options are introduced at a later date. It also helps manage production costs and enables utilization of any excess capacity that may be available.

Whether it is selecting key inputs like the best feed, the best breed and providing intensive technical and operational support to ensure a quality product is produced or employing modern processing techniques, meeting the highest quality standards and specifications or using innovative, convenient ordering and distribution where the customer gets involved making final product selection, San Miguel has demonstrated an ability to transform itself to meeting customer needs – a distinct offering for future success.