Seeking out Salmonella

By Ron Meijerhof, Senior technical specialist, Hybro B.V. and published in International Hatchery Practice Volume 19 Number 6, 2005 - Thinking of the hatchery as a crossroad is a useful analogy for understanding why it plays such a key role in the control of Salmonella. Eggs from various origins arrive, and resulting chicks depart for different farms.

The hatchery environment creates almost perfect conditions for Salmonella to flourish – and the intestinal tract of the newly hatched chick is easily colonised, so effective control at this stage is crucial.

The best way to avoid cross-contamination is to prevent contaminants from entering the hatchery in the first place. This relies on the breeder farms for the proper management of bio-security, feed quality, limited access for visitors, effective rodent and hygiene control and other factors.

Yet even with stringent measures at breeder farm level, we cannot eliminate the risk of contamination completely. So regular checks of Salmonella status in breeder flocks, for example by monitoring fluff in the hatchers after every take-off, are essential to identify contamination quickly – and respond accordingly.

And still, because chicks are hatched between contamination and identification, cross-contamination can occur. Even when a flock is identified as Salmonella positive, eggs will often still be processed in the hatchery, especially when we find a more exotic Salmonella strain.

We disinfect eggs and collect them separately, to avoid cross-contamination between farms. We do not set floor or washed eggs from a contaminated flock, and we mark eggs clearly, to identify possible risk.

But whatever we do, we will inevitably have to act to avoid contamination in the hatchery, even if no Salmonella has been reported in the breeder flocks.

Taking action by flow control

Contamination can be minimised by controlling three different flows in a hatchery:

- the flow of materials (including eggs)

- the flow of people

- the flow of air

For materials, people and air – flow should be directed from the cleanest, lowest-risk area to the dirtiest, highest-risk area.

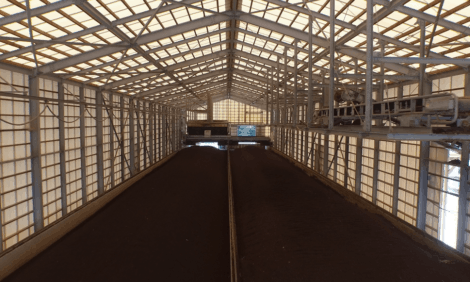

Typically, the cleanest area is directly after disinfection of eggs and materials: normally the setter room. From here, flow should be directed forward through transfer rooms, hatchers, chick handling and chick storage, to arrive finally at waste removal and tray-washing: the dirtiest areas.

Putting standard operating procedures in place will improve the management of risk in an established hatchery. However, the greatest improvements can be achieved by carefully planning the logistics of a new hatchery by these principles. This makes it easier for everyone in the hatchery to get it right, than to get it wrong. All too often, hatcheries are designed so that, for example, the easiest way to get to the canteen is through a clean area, perhaps the setter room – even for people working in waste removal!

Simple measures, like the adoption of differently coloured clothing by personnel from different areas of the hatchery, can be highly effective in identifying workgroups immediately - and makes it much easier to prevent ‘backwards’ movement.

Controlling the flow of air is more challenging – but it too must be prevented from moving from a relatively dirty area to a cleaner zone. Doors help to limit airflow, but their effectiveness should not be overestimated. In many hatcheries, doors are simply left open during working hours, as they obstruct normal working procedures too much.

The best ‘door’ for airflow control is a difference in pressure. By ensuring that air pressure is highest in the cleanest area and gradually reduced towards the dirtiest area, airflow is directed ‘forward’, from clean to dirty areas, correctly.

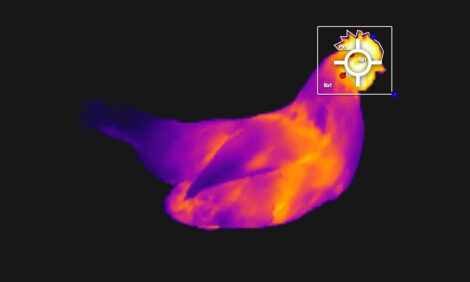

Salmonella spreads mainly from the hatcher, so it is important that air pressure here is correctly maintained, particularly when the hatcher-door is opened. When a flock is known to be contaminated, it should be held in a separate hatcher with the doors closed, and processed at the end of the day, after the uncontaminated flocks.

A hatchery is a crossroad, where eggs and chicks from different farms meet. By managing the flow through this crossroad effectively, so that materials, people and air move as directed from clean to dirty areas, the risk of cross-contamination will be significantly reduced.

Source: Hybro B.V. - October 2005